High-strength geogrid and its preparation method

A geogrid and high-strength technology, applied in the field of high-strength geogrid and its preparation, can solve the problems of aging, damage and deformation of the geogrid, and achieve the effects of delaying aging, improving flexibility and promoting anti-oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

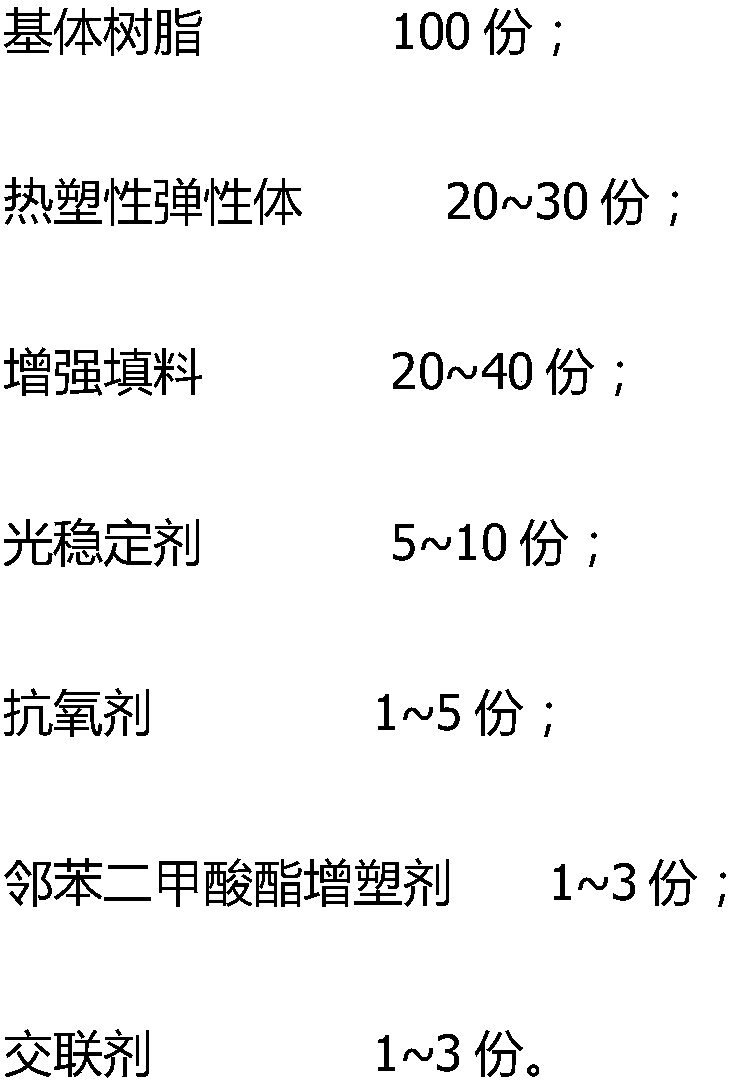

Method used

Image

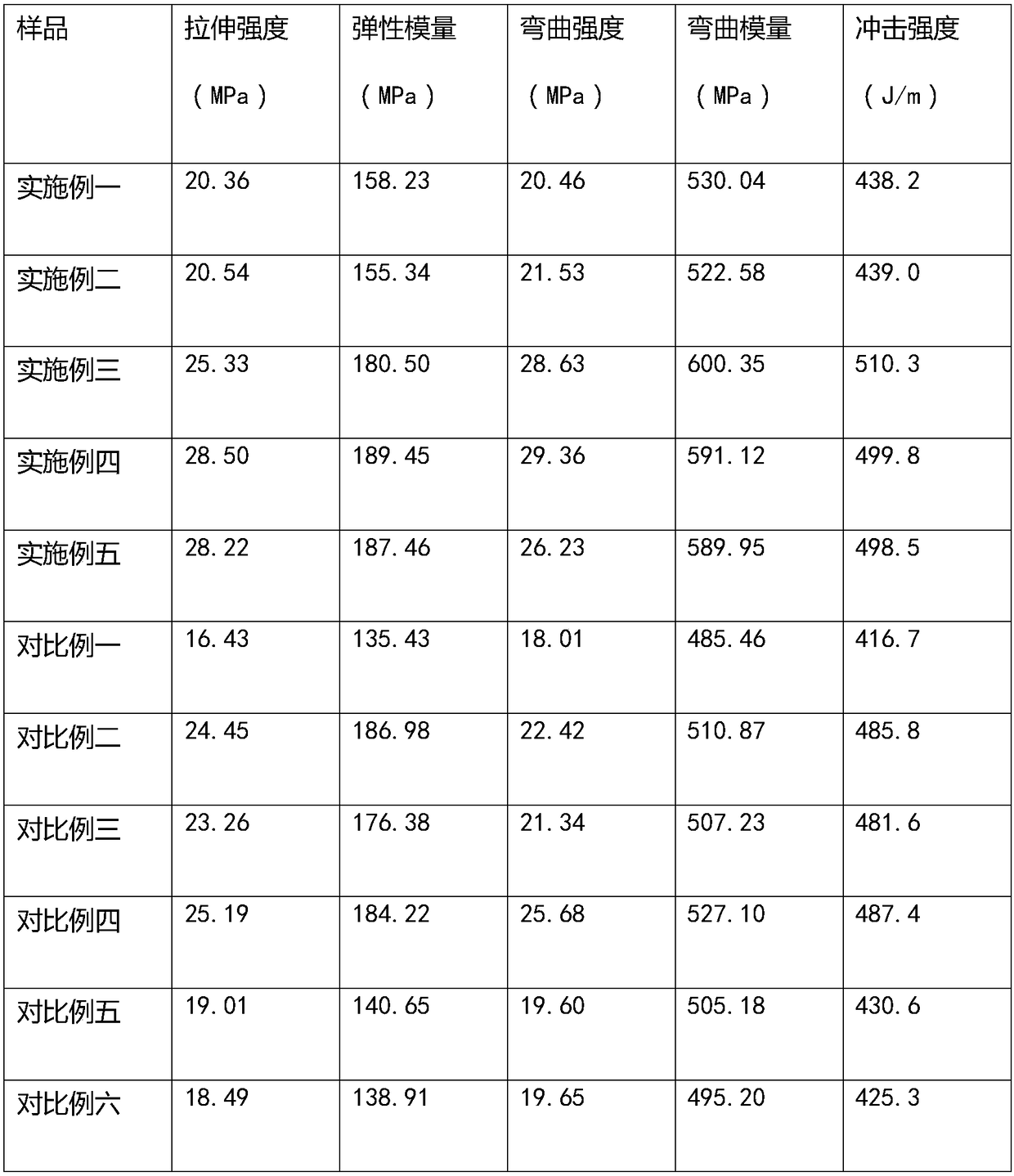

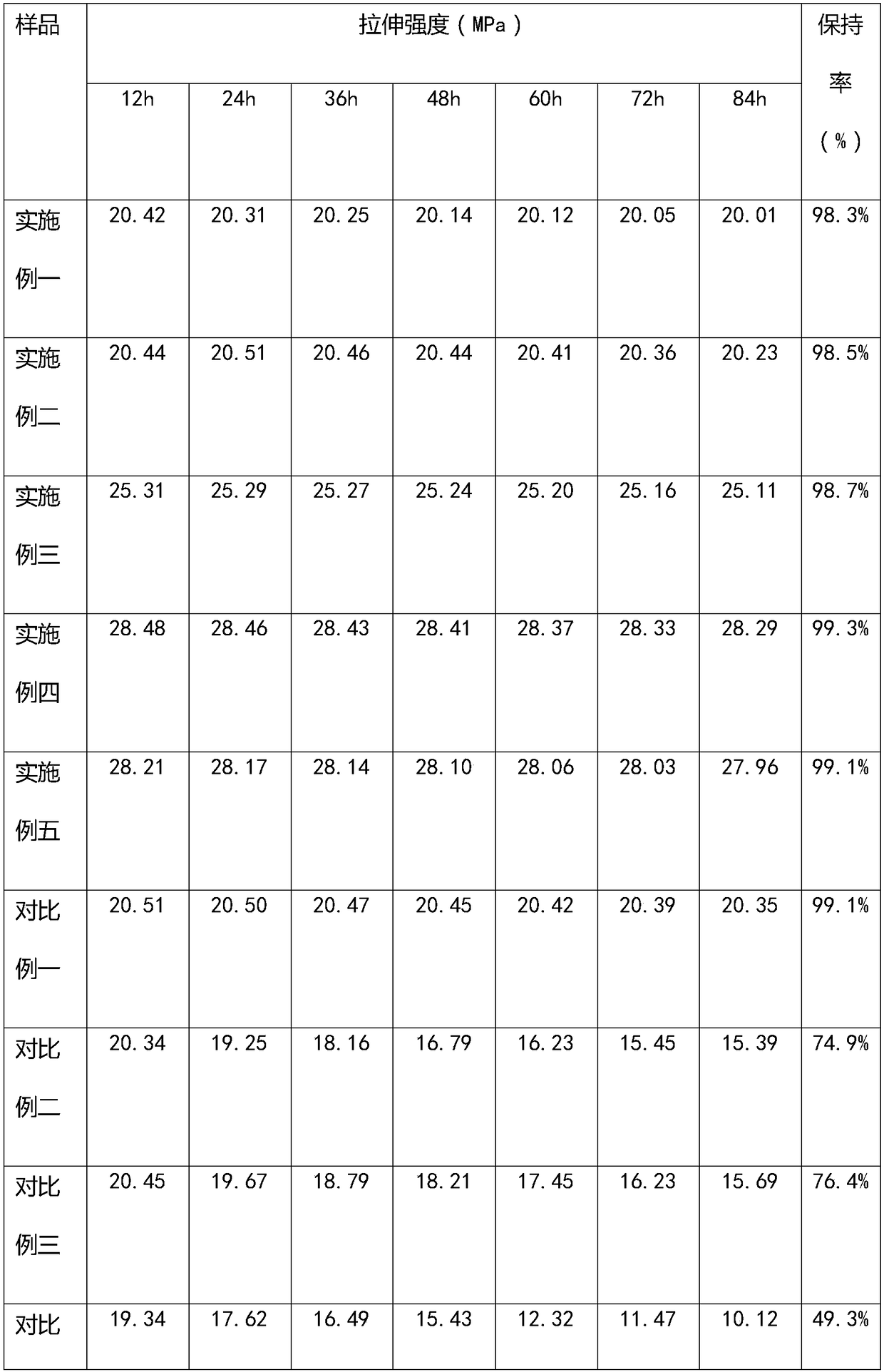

Examples

Embodiment 1

[0042] (1) 20 parts of nano-calcium carbonate and 1 part of carbon nanotubes are dried in an oven at 100°C;

[0043] (2) Weigh 80 parts of PE, 20 parts of phenolic resin, 10 parts of EPDM rubber, 15 parts of styrene-butadiene rubber, 20 parts of nano-calcium carbonate, and 1 part of carbon nanotubes into a high-speed mixer, and mix at high speed for 10 minutes; Then add 5 parts of 2-hydroxy-4-n-octyloxybenzophenone, 1 part of diphenylamine, 1 part of diisooctyl phthalate and 1 part of crosslinking agent into the high-speed mixer, and mix at high speed for 20 minutes;

[0044] (3) Put the above blend into an extruder for melt extrusion, the temperature of the barrel of the extruder is 192° C., and the rotating speed of the screw of the extruder is 180 r / min;

[0045] (4) The above-mentioned melt is formed into a sheet through a three-roll calender, and then punched with a die by a punching machine, heated to 82° C. through an orifice plate, and then stretched.

Embodiment 2

[0047] (1) 25 parts of nano-silica, 1.2 parts of carbon nanotubes, and 5 parts of carbon fiber are dried in an oven at 100 ° C;

[0048] (2) Weigh 77 parts of PP, 23 parts of phenolic resin, 12 parts of EPDM rubber, 12 parts of styrene-butadiene rubber, 25 parts of nano-silica, 1.2 parts of carbon nanotubes and 5 parts of carbon fiber and add them to the high-speed mixer , mixed at high speed for 10 minutes; then added 6 parts of o-hydroxybenzotriazole, 2 parts of p-phenylenediamine, 1.5 parts of diisooctyl phthalate and 1 part of crosslinking agent to the high-speed mixer, and mixed at high speed for 20 minutes;

[0049] (3) Put the above blend into an extruder for melt extrusion, the temperature of the barrel of the extruder is 192° C., and the rotating speed of the screw of the extruder is 180 r / min;

[0050] (4) The above-mentioned melt is formed into a sheet through a three-roll calender, and then punched with a die by a punching machine, heated to 82° C. through an orifi...

Embodiment 3

[0052] (1) 30 parts of talcum powder, 1.5 parts of carbon nanotubes, and 10 parts of glass fiber are dried in an oven at 100 ° C;

[0053] (2) Take by weighing 75 parts of PVC, 25 parts of phenolic resin, 15 parts of EPDM rubber, 10 parts of styrene-butadiene rubber, 30 parts of talcum powder, 1.5 parts of carbon nanotubes and 10 parts of glass fiber and join in the high-speed mixer, Mix at high speed for 10 minutes; then add 7 parts of 4-tert-butylphenyl salicylate, 3 parts of diphenylamine, 2 parts of diisooctyl phthalate and 1 part of crosslinking agent to the high-speed mixer, and mix at high speed for 20 minutes ;

[0054] (3) Put the above blend into an extruder for melt extrusion, the temperature of the barrel of the extruder is 192° C., and the rotating speed of the screw of the extruder is 180 r / min;

[0055] (4) The above-mentioned melt is formed into a sheet through a three-roll calender, and then punched with a die by a punching machine, heated to 82° C. through a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com