A rotatable electroplating hanger

A technology of electroplating hangers and fixtures, applied in electrolytic components, electrolytic processes, etc., can solve the problems of low versatility and limited number of one-time electroplating workpieces, and achieve the effects of reducing costs, stable and reliable suspension, and large quantities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

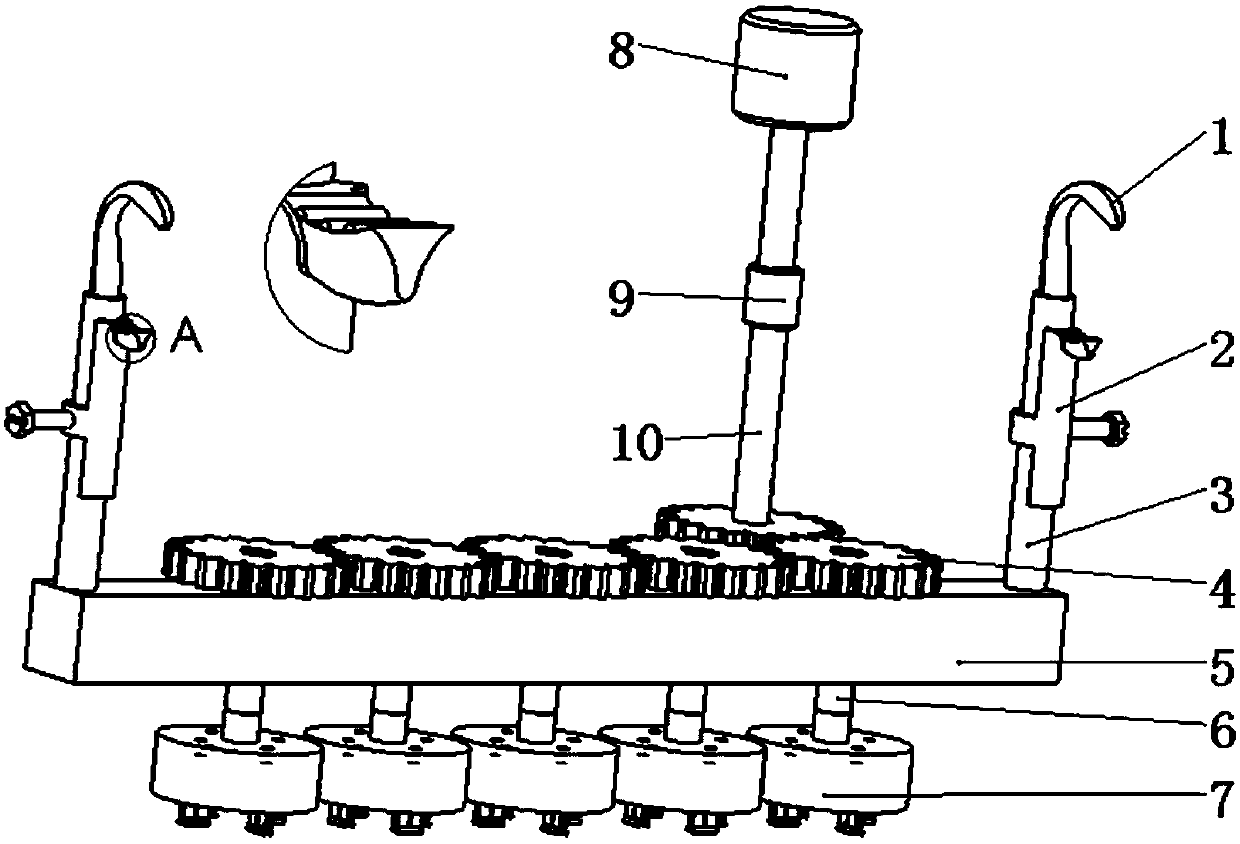

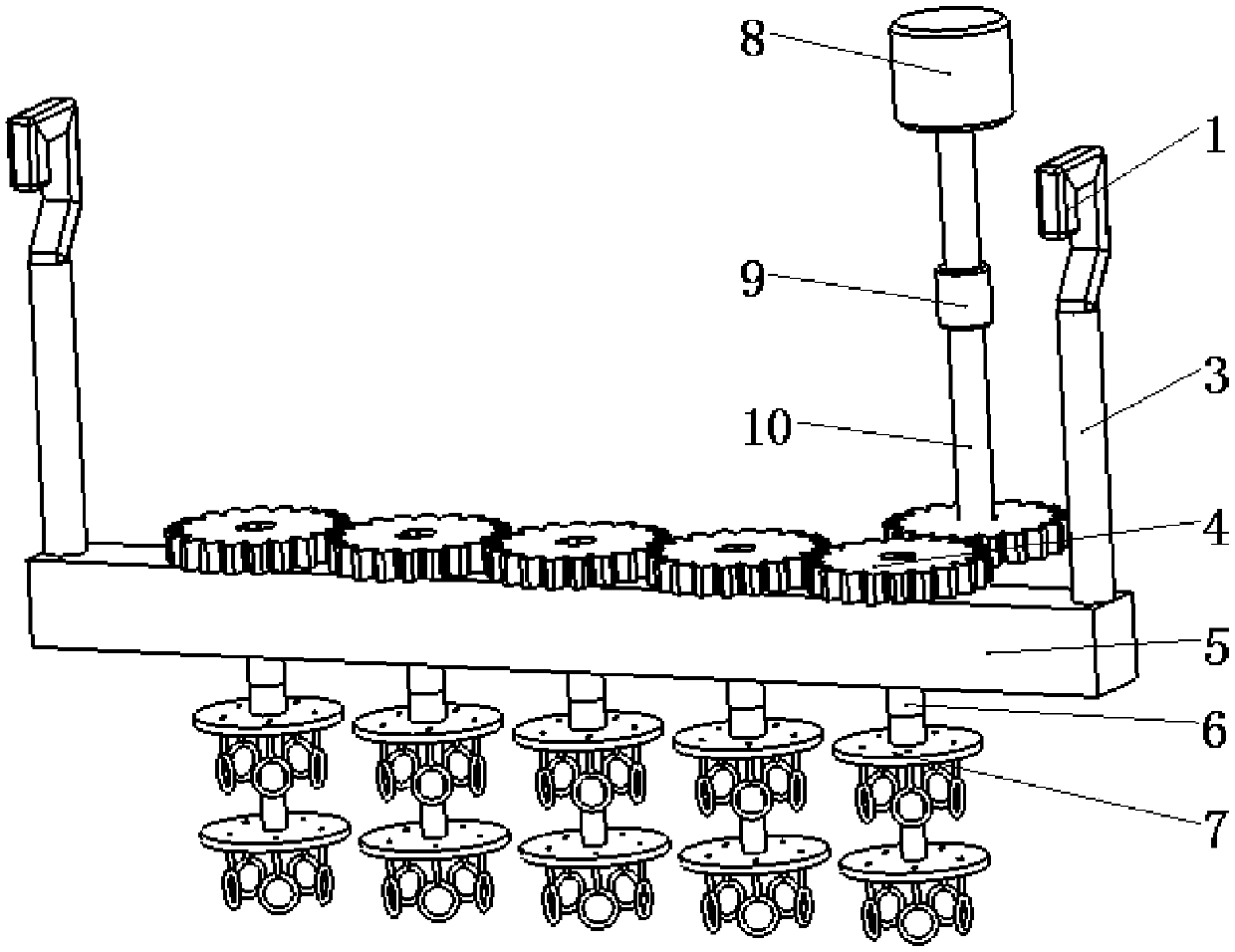

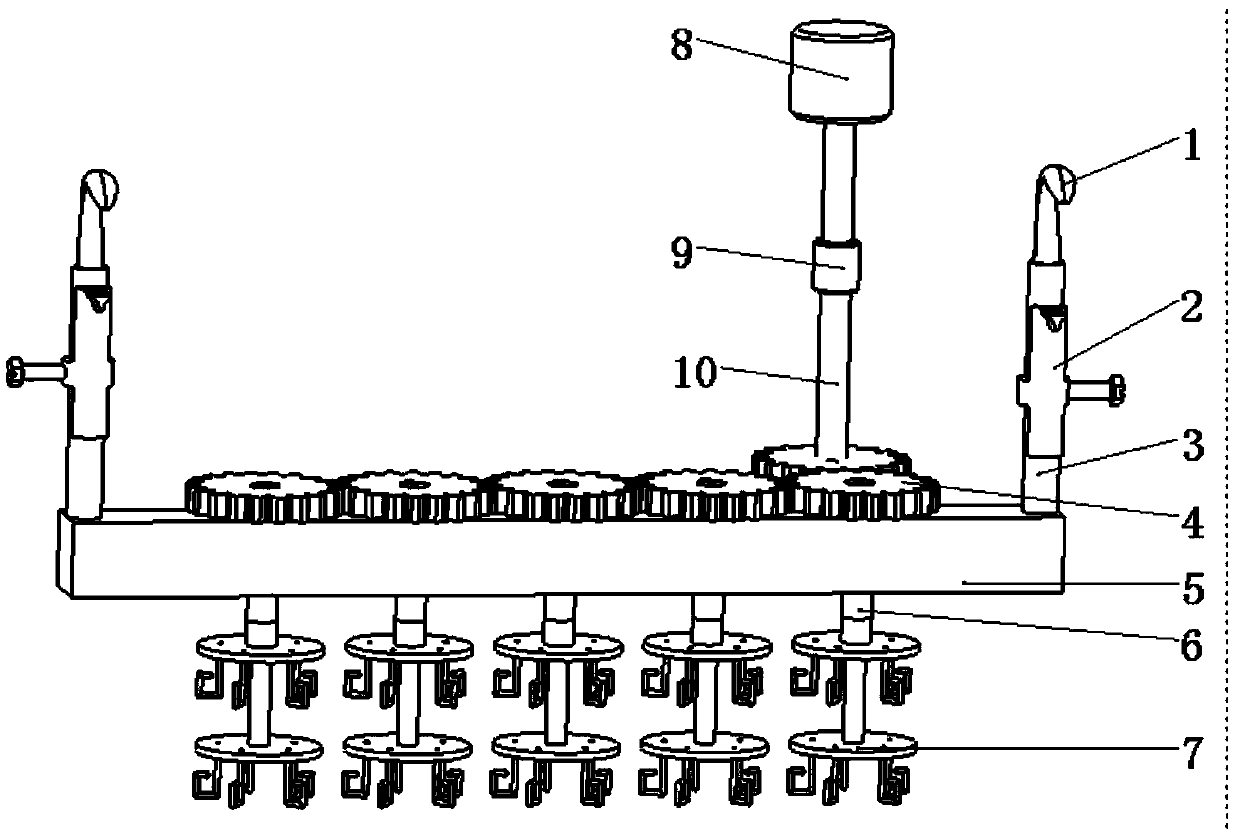

[0032] Such as Figure 1-3As shown, a kind of rotatable electroplating hanger that the present invention provides, comprises main bar 3, crossbeam 5, several gears 4, gear shaft 6 and the fixture 7 that is used for workpiece of different shapes and sizes; The two ends of described crossbeam 5 are vertical Fix the main rod 3, the upper end of the main rod 3 is provided with a hook 1, the shape of the hook 1 is arc-shaped or rectangular, when the hook 1 is arc-shaped, the main rod 3 is provided with a slidable clamping device 2 to ensure that the hook 1 Reliable contact with the pole bar, no de-electrification, and no swinging of the hanger during the electroplating process; a number of through holes are opened on the beam 5, and one of the gears 4 is assembled with the rotating shaft 10 and connected to the motor through the coupling 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com