Revolving drum sprayed concrete quantitative feeding controlling device

A technology of shotcrete and quantitative feeding, which is applied in wellbore lining, shaft equipment, earth-moving drilling, etc. Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

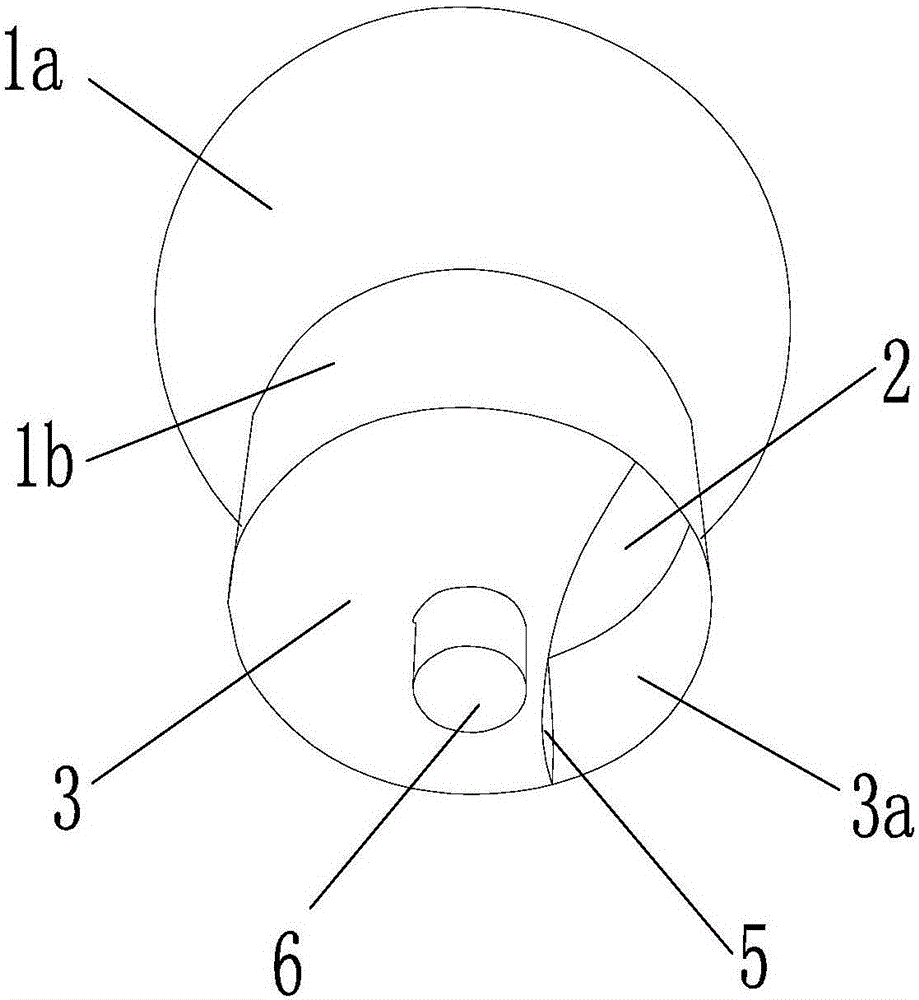

[0012] to combine figure 1 — figure 2 As shown, a rotary drum type shotcrete quantitative feeding control device is mainly composed of an outer cylinder 1, a baffle plate 2, a bottom plate 3, a partition plate 4, a rotor 5 and a transmission shaft 6. Wherein, the outer cylinder 1, the baffle plate 2, and the bottom plate 3 are fixed together and remain still during use; the partition plate 4, the rotor 5 and the transmission shaft 6 are fixed together, and are driven by a motor to rotate synchronously.

[0013] The outer cylinder 1 is composed of an upper inverted cone cylinder and a lower cylinder integrally arranged. The upper part of the outer cylinder 1 adopts an inverted cone cylinder to form a structure with a large top and a small bottom, which is convenient for pouring dry ingredients.

[0014] The bottom plate 3 is horizontally and fixedly arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com