Water-cooled biomass boiler anti-coking method and device

A biomass boiler and anti-coking technology, which is applied in the field of boiler manufacturing, can solve the problems of high manufacturing cost, insufficient fuel combustion, and high labor intensity, and achieve the effects of ensuring universality, reducing heating temperature, and solving coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further illustrate the present invention by the following examples, do not limit the present invention in any way, under the premise of not departing from the technical solution of the present invention, any modification or change that those of ordinary skill in the art that the present invention is done to realize easily will all be fall within the scope of the claims of the present invention.

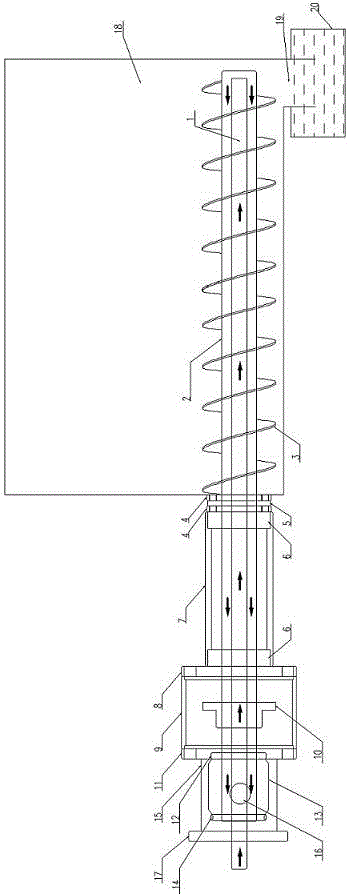

[0014] according to figure 1 , figure 2 As shown, the present invention includes: water inlet pipe 1, hollow shaft 2, spiral blade 3, dustproof baffle 4, asbestos pad 5, bearing 6, bearing sleeve 7, flange 8, gear cover 9, gear 10, flange 11 , Water seal static ring 12, water seal dynamic ring 13, water seal block 14, water tank 15, outlet pipe 16, water tank block 17, furnace 18, ash falling channel 19, slag pit 20;

[0015] The hollow shaft 2 is welded with a spiral blade 3, and the hollow shaft 2 is provided with a water inlet pipe 1 extending in, and a gap not smaller th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com