Waste drilling fluid solid-liquid separation assessment method

A waste drilling fluid, solid-liquid separation technology, applied in the direction of material analysis, material analysis through optical means, instruments, etc., can solve the problems that cannot fully reflect the effect of solid-liquid separation, large amount of waste liquid output, high moisture content of mud cake, etc. , to achieve accurate solid-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

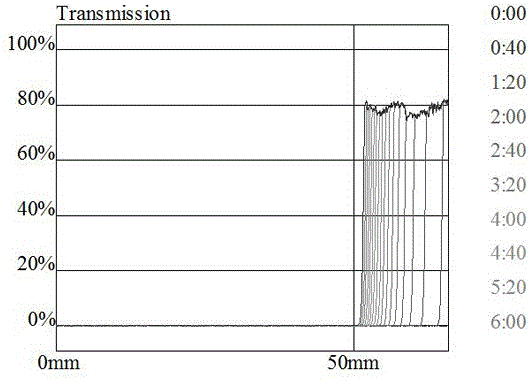

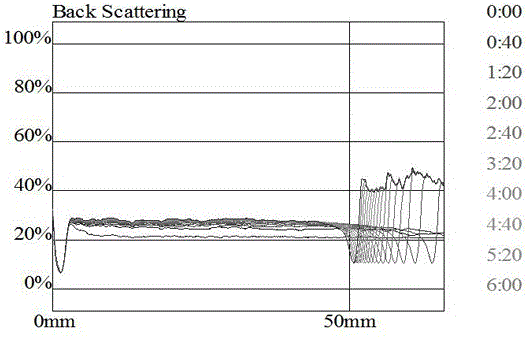

[0026] As a preferred embodiment of the present invention, it discloses a method for evaluating the solid-liquid separation of waste drilling fluid, specifically using a Turbiscan Lab dispersion stability analyzer to evaluate the solid-liquid separation effect of waste drilling fluid, the steps are as follows:

[0027] a. Take a set volume of waste liquid as a sample, and add a gel breaker to the sample;

[0028] b. Stir the sample for 30 minutes;

[0029] c. Take an appropriate amount of sample and put it into a multiple light scattering scanning test tube, and use the Turbiscan Lab dispersion stability analyzer to measure the transmitted light and reflected light curves;

[0030] d. Analyze the solid-liquid separation effect according to the measured transmitted light and reflected light curves.

Embodiment 2

[0032] As the best implementation mode of the present invention, it adopts Turbiscan Lab dispersion stability analyzer to evaluate the solid-liquid separation effect of waste drilling fluid, and the steps are as follows:

[0033] a. Take 400ml of waste liquid and stir for 30 minutes before adding gel breaker. ;

[0034] b. Stir the sample for 30 minutes;

[0035] c. Take 20ml of the sample and put it into the multiple light scattering scanning test tube, and use the Turbiscan Lab dispersion stability analyzer to measure the curve of transmitted light and reflected light;

[0036] The Turbiscan Lab Dispersion Stability Analyzer sets the scanning range to 5mm-75mm, and the scanning time interval is set to 40min;

[0037] d. Analyze the solid-liquid separation effect according to the measured transmitted light and reflected light curves. The specific steps are:

[0038] (1) Analyze the change in particle volume concentration between the supernatant and the lower turbid liquid:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bleeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com