Method and apparatus for measuring thermal diffusivity of materials through transient fluorescence

A technology for measuring thermal diffusivity and fluorescence, applied in the direction of material thermal development, etc., can solve the problems of contact resistance, sample damage, sample damage, etc., and achieve the effect of eliminating system errors, low material requirements, and easy acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

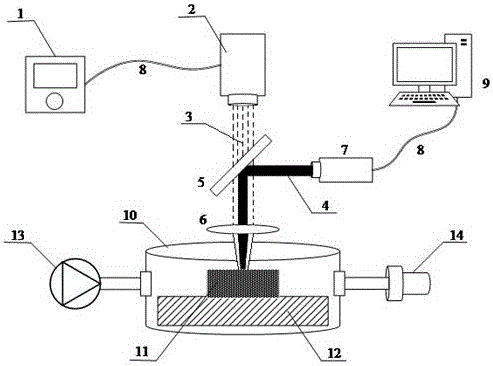

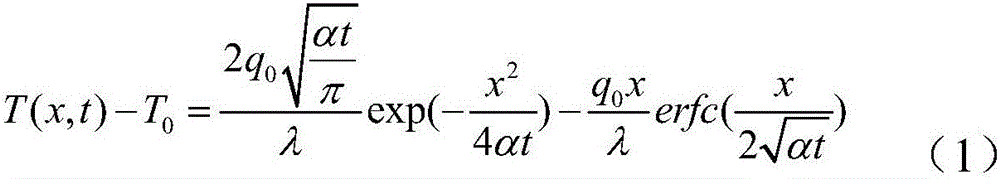

[0030] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as figure 1 As shown, a device for measuring the thermal diffusivity of materials by transient fluorescence includes a semiconductor pulse laser, a vacuum sample chamber, a fluorescence spectrometer 7 and a data collection computer 9, wherein the semiconductor pulse laser is located above the vacuum sample chamber, and between the laser and the vacuum sample chamber A focusing lens 6 and a spectroscope 5 are arranged between the vacuum sample chamber and the fluorescence spectrometer through the spectroscope 5 to transmit the fluorescence signal fed back after the sample is excited, and the fluorescence spectrometer 7 is connected to the data collection computer 9 through the data line 8 .

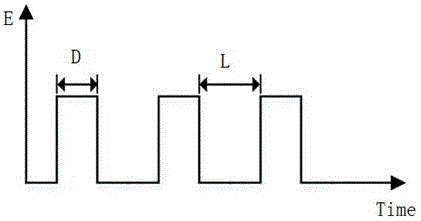

[0031] The semiconductor pulsed laser includes a semiconductor laser 2 and a pulse signal generator 1, which together form a sample heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com