Deformation control method of high-pier and long-span bridge track of railway

A deformation control and bridge technology, applied in the direction of instrumentation, geometric CAD, calculation, etc., can solve the problems of increased line complexity, increased bridge ratio, lack of high-pier and long-span bridge track deformation control methods, etc., to reduce research work problems, The effect of improving efficiency and improving the safety of train traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Research on the seamless line of ballasted rigid frame bridge with high piers and long spans,

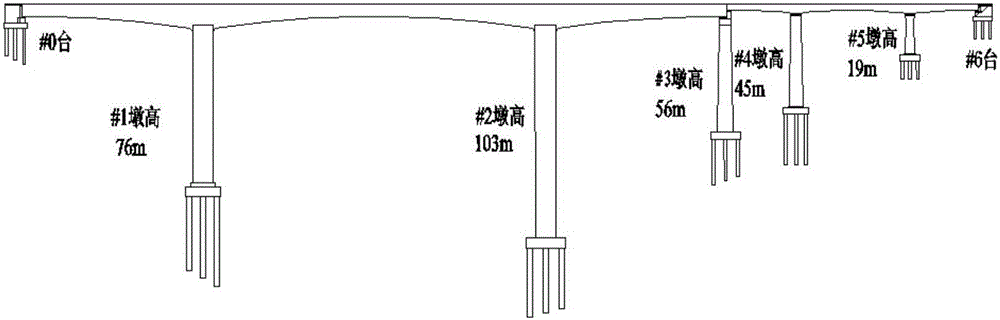

[0090] Rigid-frame bridges are commonly used in high-pier and long-span structures when crossing mountains, canyons, and large rivers. Taking the Chahe Super Bridge on the Changkun Railway as an example, the seamlessness of this type of bridge is studied. The general situation of the bridge is as follows: Changkun Passenger Dedicated Chahe Super Bridge is located in the section from Changkun Passenger Dedicated Yuping to Kunming. (36+56+36)m continuous beam. The general layout of the Chahe Bridge is as follows figure 1 shown.

[0091] Table 5 below summarizes the design values of the longitudinal stiffness of the piers of the Chahe Super Bridge.

[0092] Table 5 Summary of Longitudinal Stiffness of Chahe Bridge Pier Abutments

[0093]

[0094] 2. Common seamless line calculation

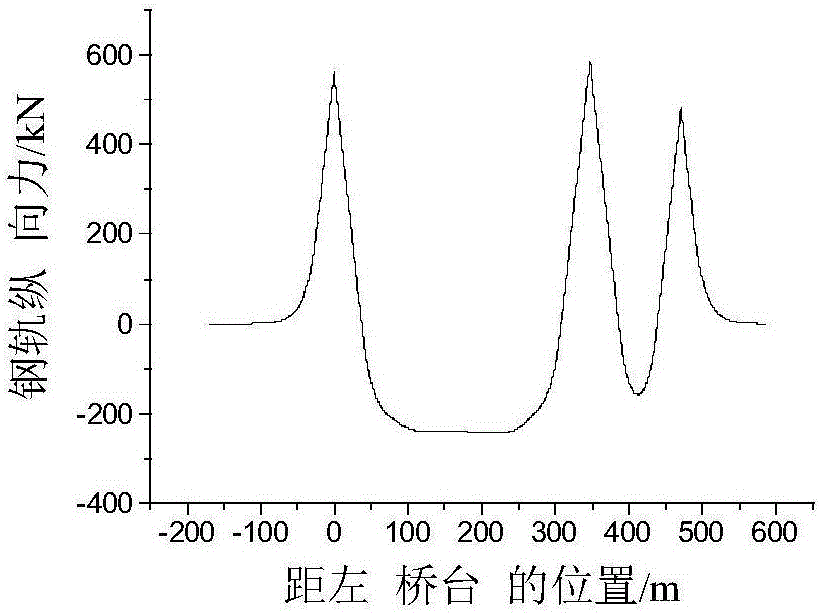

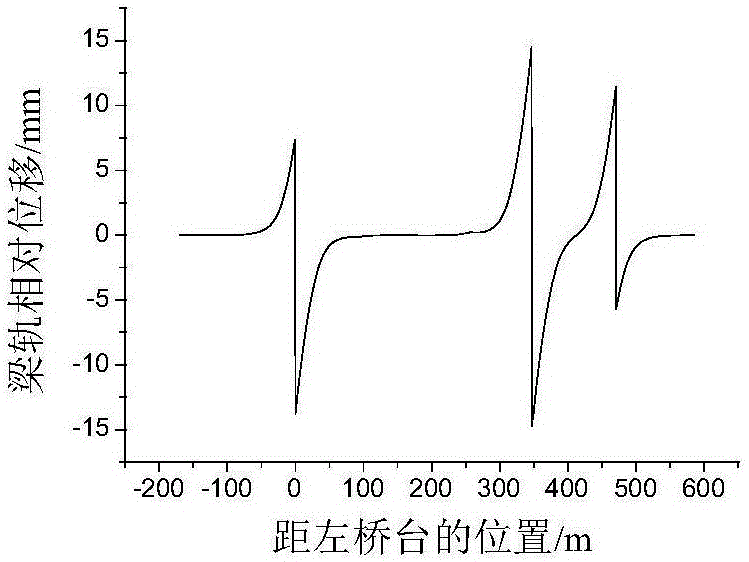

[0095] (1) Telescopic working condition

[0096] According to the "Code for Design of...

Embodiment 2

[0144] Calculation of ballast track seamless route of Xingfuyuan Bridge.

[0145] General situation of the bridge: Xingfuyuan double-line extra-large bridge span layout is 8×32m simply supported beam + (48+5×80+48)m continuous rigid frame + 5×32m simply supported beam, with a total of 20 spans, 19 piers and 2 bridges. The numbers of piers from the Guiyang side to the Guangzhou side are 1#, 2#...21#. The whole bridge is located on the circular curve of R9000m. The highest rail temperature is 59.5°C, the lowest rail temperature is -4.2°C, the design locked rail temperature is 32±5°C, the maximum temperature difference can reach 59.5-(32-5)=32.5°C when heating up, and the maximum temperature difference can reach 32+5- when cooling down (-4.2) = 42.2°C. The height of the piers and abutments is shown in Table 8, and the span layout of the main bridge is shown in Figure 8 shown.

[0146] Table 8 Pier height table

[0147]

[0148] 2. Wind load effect

[0149] Due to the hi...

Embodiment 3

[0164] 5.5 Research on Stiffness of Continuous Girder Bridge Pier

[0165] 5.5.1 Calculation and control standards for track calculation of seamless lines on bridges

[0166] The main calculation content of the seamless line on the bridge includes the strength of the rail, the stability of the line, the rapid relative displacement of the beam and rail under the braking condition of the train, and the fracture value.

[0167] 5.5.5.1 Rail strength

[0168] Rail strength checking is an important task in the design and calculation of seamless lines. Its purpose is to ensure that the maximum working stress of the rail section must be within the allowable stress range of the rail. The rail strength checking formula is:

[0169]

[0170] where σ s In order to consider the rail yield strength of welded joint quality; K is the safety factor, which is generally taken as 1.0 or 1.3, considering the influence of factors such as rail fatigue stress, residual stress, and welded joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com