Servo driving connection rod type variable degree-of-freedom connection rod mechanism for oxygen-acetylene cutting machine

A servo-driven, link-type technology, applied in the field of machinery, can solve the problems such as the variable degree of freedom mechanism of the gas cutting blanking machine, the decline of the dynamic performance of the manipulator, and the large cumulative error of the manipulator, so as to achieve a compact structure, improve stability and reliability. High performance and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

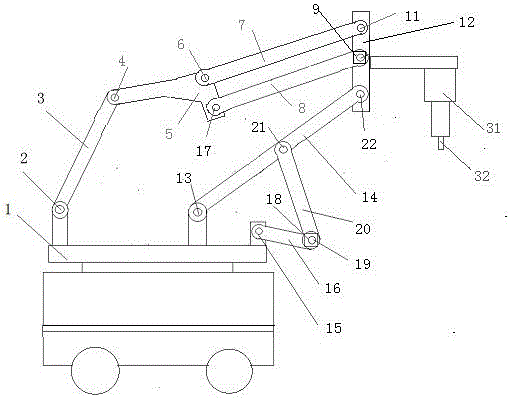

[0007] A servo-driven link-type variable-degree-of-freedom link mechanism for a gas cutting cutting machine, including a base 1, a boom lifting mechanism, a gripper link pitching mechanism, a gripper 31, a torch 32, and a servo drive device and the first locking device 9 and the second locking device 19; the base 1 is installed on a movable slewing platform; the boom lifting mechanism is composed of a boom 14 and a lifting mechanism, and the boom 14 passes through the Seven rotating pairs 13 are connected on the base 1, the fourth connecting rod 16 of the lifting mechanism is connected on the base 1 through the eighth rotating pair 15, and the other end is connected with the fifth connecting rod 20 through the ninth rotating pair 18, the fifth The other end of the connecting rod 20 is connected to the boom 14 through the tenth rotating pair 21; the gripper link pitch mechanism is composed of the gripper link 12 and the pitch mechanism, and the gripper link 12 passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com