Construction technology and construction method for large-particle-size pebble stratum super-deep foundation pit in strong water permeation environment of Yellow River flood plain

A construction method and technology of construction technology, applied in the direction of infrastructure engineering, excavation, protection devices, etc., can solve the problems of water leakage, inability to work, and difficulties in foundation pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

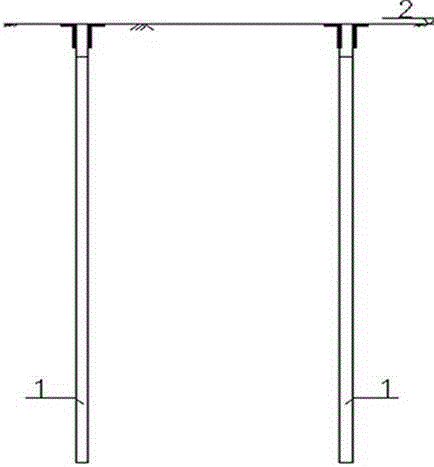

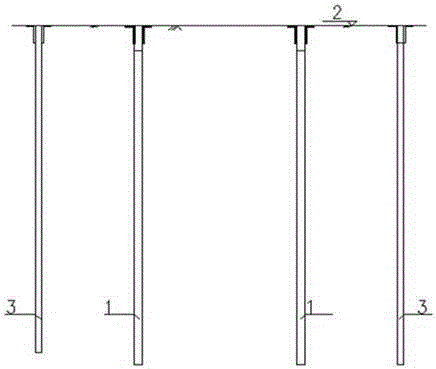

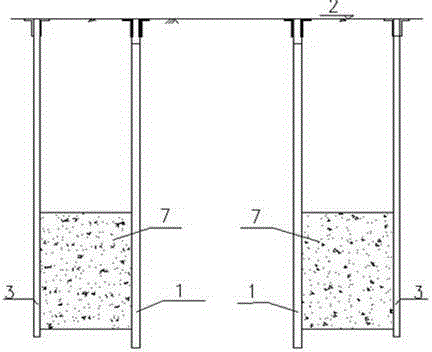

[0057] A construction technique for ultra-deep foundation pits in large-diameter pebble layers in the floodplain environment of the Yellow River with strong water permeability. The overall construction steps are shown in Figure 1-Figure 15 shown. Including enclosure structure construction, precipitation construction and main structure construction. It is characterized in that the design thickness of the construction ground connection wall of the enclosure structure is 1.2m, and it is divided into two types of width: the first type is a "one" shape structure with a width of 4m, a total of 22 pieces; the second type is L-shaped The structure has a width of 3.7m, and there are 4 panels in total; steel joints are used between adjacent wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com