Airborne steel wire rope tension measuring device

A measuring device and wire rope technology, applied in the field of airborne wire rope tension measuring device, to achieve the effect of improving force measurement accuracy, meeting signal measurement and feedback requirements, and meeting high reliability requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

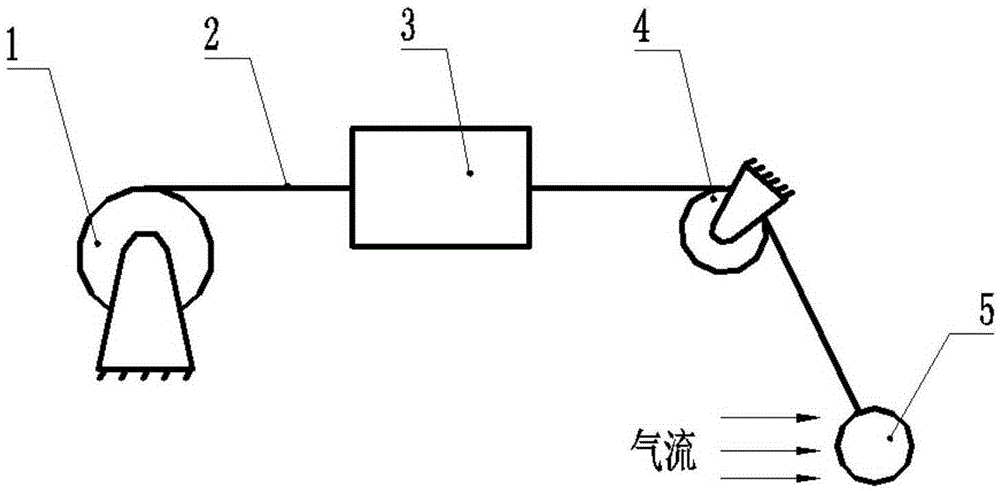

[0015] Such as figure 1 As shown, the airborne winch 1 is used as the power source on the aircraft, and the control system retracts and unwinds the steel wire rope 2 to drive the load 5 to perform retracting and unwinding motions. In order to measure the tension of the winch wire rope, a force measuring device 3 is installed on its transmission route to measure the tension of the wire rope As the control and display parameters of the control system, the fixed pulley 4 can be set according to the needs of the cable transmission line.

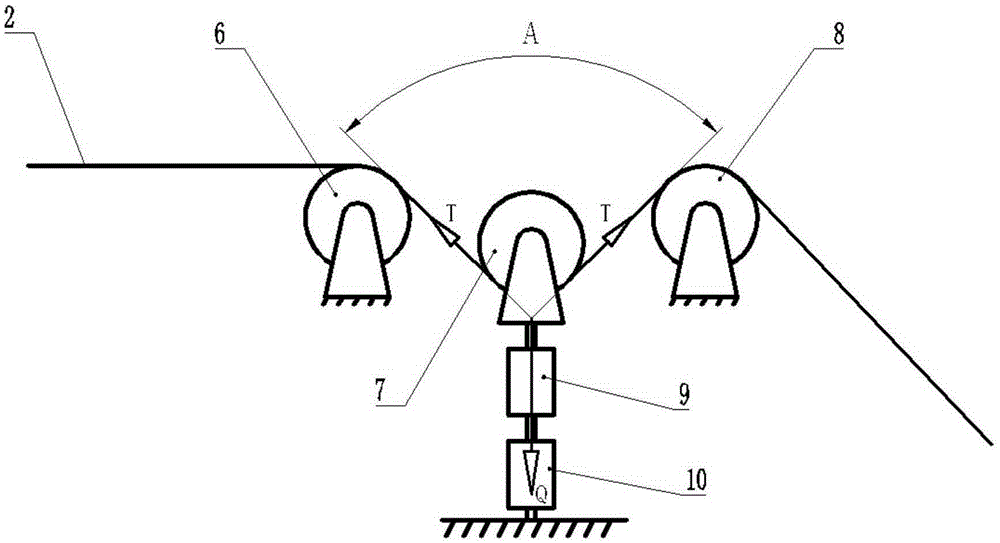

[0016] The structure diagram of the wire rope tension measuring device is as follows: figure 2 , comprising bracket, front guide wheel 6, force measuring wheel 7, rear guide wheel 8, force sensor one 9 and force sensor two 10; front guide wheel 6 and rear guide wheel 8 are installed on the body structure by bracket, force measuring wheel 7 There is a movable bracket, and the front guide wheel 6, the force measuring wheel 7 and the rear guide wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com