Simulation method for efficiently solving unsteady heat conduction problem of reactor core fuel rod

A simulation method and fuel rod technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low calculation efficiency, inability to obtain fuel rod temperature distribution, large matrix, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

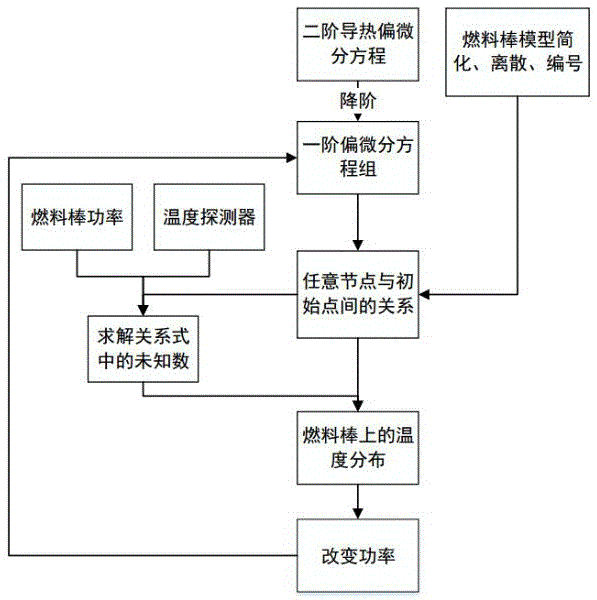

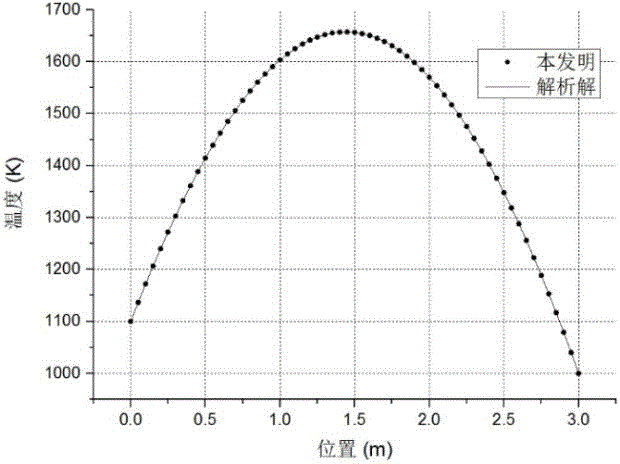

[0036] The present invention provides a simulation method for efficiently solving the problem of unsteady heat conduction of core fuel rods. The present invention will be further described below with reference to the drawings and specific embodiments.

[0037] According to figure 1 The flow chart of this method shown in figure 2 The fuel rod shown is subjected to steady-state and non-steady-state analysis to ensure the safe operation of the fuel rod.

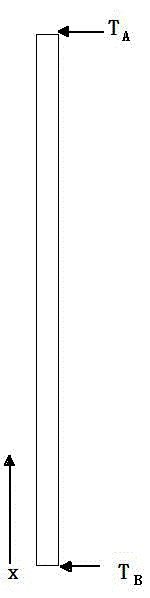

[0038] Reasonably simplify the actual fuel rod model, establish a geometric model, and discretely number the model, such as figure 2 The fuel rod shown is a long and straight cylindrical structure with fuel pellets inside and coolant outside. Therefore, the fuel rod is simplified as a one-dimensional structure in the axial direction, and the heat exchange between the fuel rod and the coolant and the heat generation part of the fuel pellet are simplified as a heat source loaded on the fuel rod.

[0039] The simplified fuel rod has a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com