Hybrid heuristic shifting bottleneck procedure for solving parallel-machine job-shop scheduling

A hybrid heuristic, job shop technology, applied in computing, instrumentation, data processing applications, etc., can solve problems such as inexact solutions, increased search time, infeasible solutions, etc., to reduce computing time, accelerate significantly, and avoid searching Unstable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

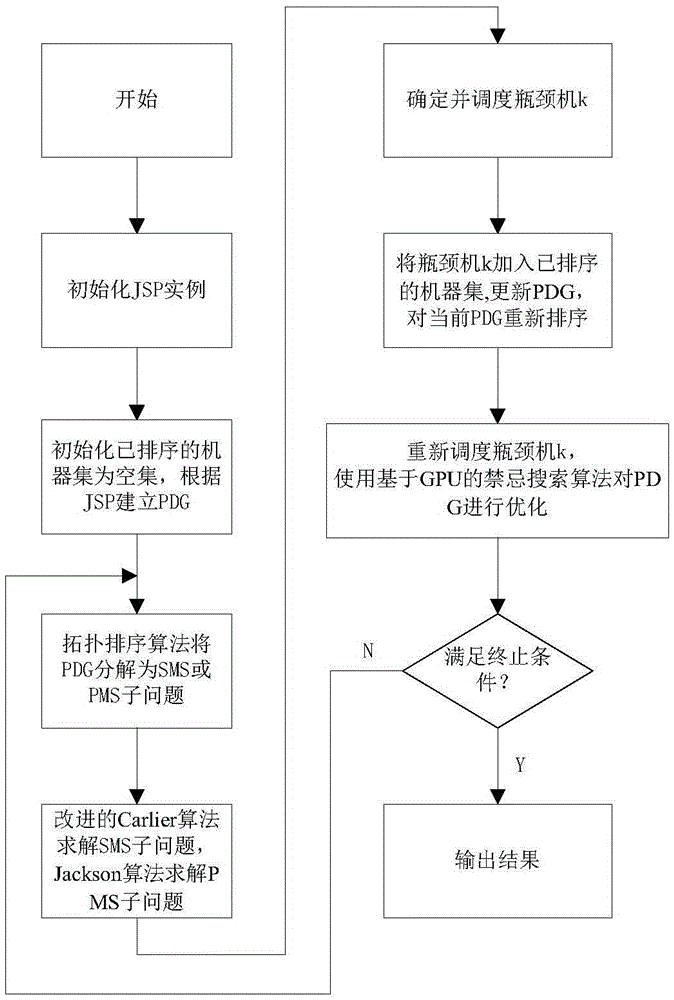

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] 1. JSP scheduling problem

[0023] JSP is a machine scheduling and optimization problem. Features of JSP: a finite set of N workpieces and M machines; each workpiece contains a process chain; each machine can process at most one process at a time; each process needs to be processed uninterruptedly on a given machine for a period of time; the goal is Find the scheduling scheme with the shortest total processing time.

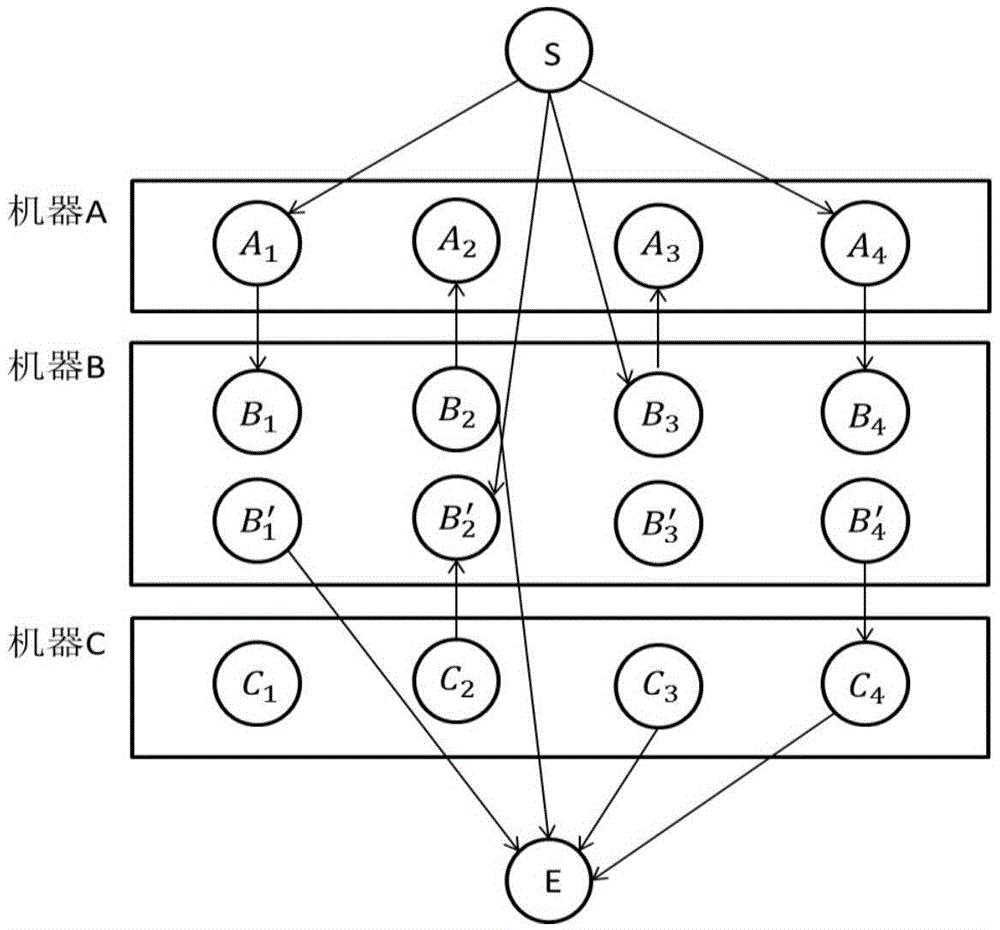

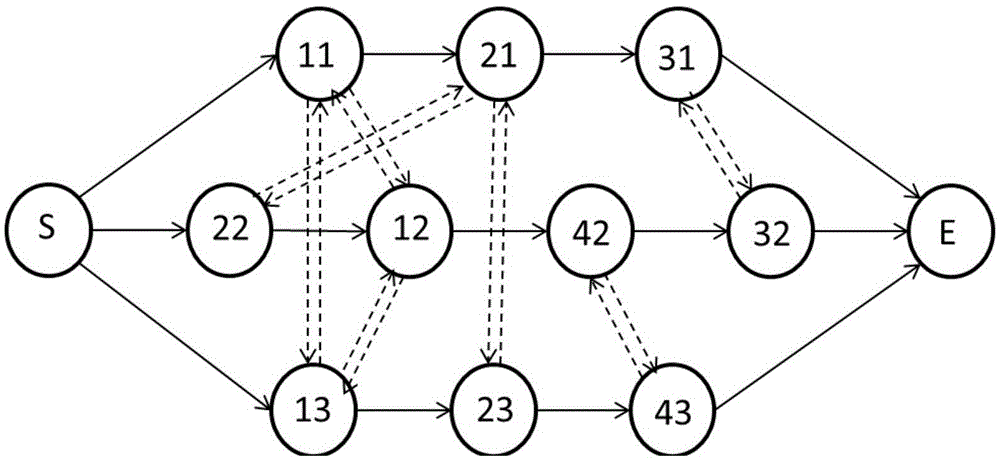

[0024] The Disjunctive Graph (DG) model can be used to represent JSP, and an example of graph G={V, C∪D} is represented as figure 2 shown. Description of the DG model: there are n workpieces and m machines of the same type in the DG model; nodes are marked from 1 to N, and N represents the total number of processes in DG; arc (i, j) links node i a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com