Trimming mechanical arm

A manipulator and scissor handle technology, applied in agricultural machinery and implements, cutting tools, applications, etc., can solve problems such as affecting users' normal power consumption, staff injury, low work efficiency, etc., to eliminate potential hidden dangers, reduce labor intensity, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

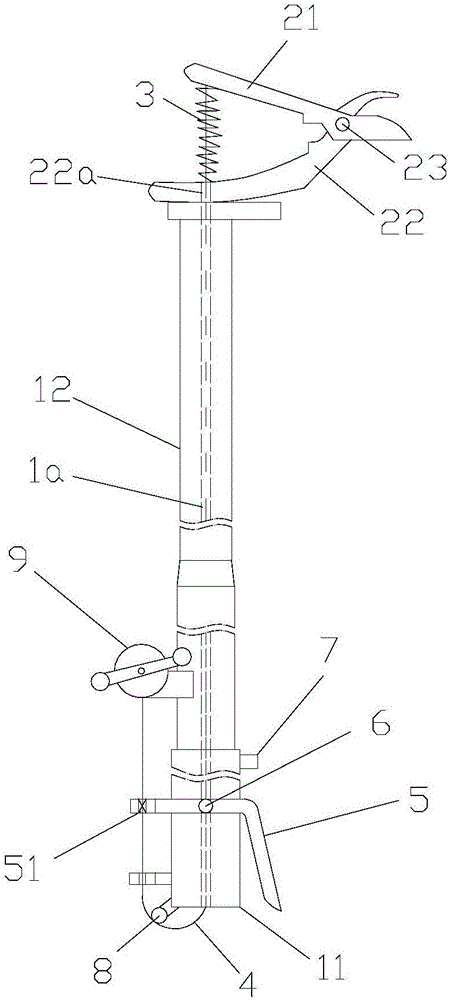

[0016] As shown in the figure: the pruning manipulator of the present embodiment comprises an insulating rod, a scissors located on the insulating rod, a traction rope 4 and an insulating handle 5; 22 and shaft I23; the cutting edges of the movable blade 21 and the fixed blade 22 are curved in an arc shape, and the length of the blade end of the movable blade 21 is greater than that of the fixed blade 22; the length of the blade end of the movable blade 21 and the fixed blade 22 A return spring 3 for providing a reset force is provided between the scissor handles; an axial channel 1a is provided in the insulating rod, and the scissor handle of the fixed blade 22 is fixed on the top of the insulating rod and is provided with the axial channel 1a Connected through hole 22a, one end of the traction rope 4 is connected with the insulating handle 5, and the other end is connected with the scissor handle of the movable blade 21 after passing through the axial passage 1a and the throu...

Embodiment 2

[0021] The pruning manipulator of the present embodiment is structurally the same as the pruning manipulator parts in the first embodiment, the difference is only in the composition of the glass fiber material; in the present embodiment, the glass fiber material comprises the following components in parts by weight: quartz sand 31 parts, 10 parts of limestone, 5 parts of dolomite, 1 part of boric acid, 4 parts of Glauber's salt, 2 parts of fluorite, 1 part of pyrophyllite, 9 parts of alumina, and 10 parts of silica. The materials of the above components are melted and sintered into 20mm rods or spheres, and then heated and remelted to make finer 3-60um fibers, and then the fibers are made into super-strong fiber rods by reverse winding with a roller machine or barrel. The material has high strength. After testing, the tensile strength of a single fine fiber can reach 2840Mpa, and the elastic modulus can reach 86000Mpa, which is several times higher than that of high-strength g...

Embodiment 3

[0023] The pruning manipulator of the present embodiment is structurally the same as the pruning manipulator parts in the first embodiment, the difference is only in the composition of the glass fiber material; in the present embodiment, the glass fiber material comprises the following components in parts by weight: quartz sand 35.5 parts, 13.5 parts of limestone, 9.5 parts of dolomite, 3.5 parts of boric acid, 7 parts of Glauber's salt, 5.5 parts of fluorite, 3 parts of pyrophyllite, 12 parts of alumina, and 12 parts of silica. The materials of the above components are melted and sintered into 20mm rods or spheres, and then heated and remelted to make finer 3-60um fibers, and then the fibers are made into super-strong fiber rods by reverse winding with a roller machine or barrel. The material has high strength. After testing, the tensile strength of a single fine fiber can reach 2985Mpa, and the elastic modulus can reach 88500Mpa, which is several times higher than that of hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com