Underground pipe irrigation system and construction method thereof for sponge city

An irrigation system and sponge city technology, applied in the sponge city underground pipe irrigation system and its construction field, can solve problems such as unfavorable farmland irrigation, secondary pollution of river channels, water source pollution, etc. The effect of preventing road accumulation of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

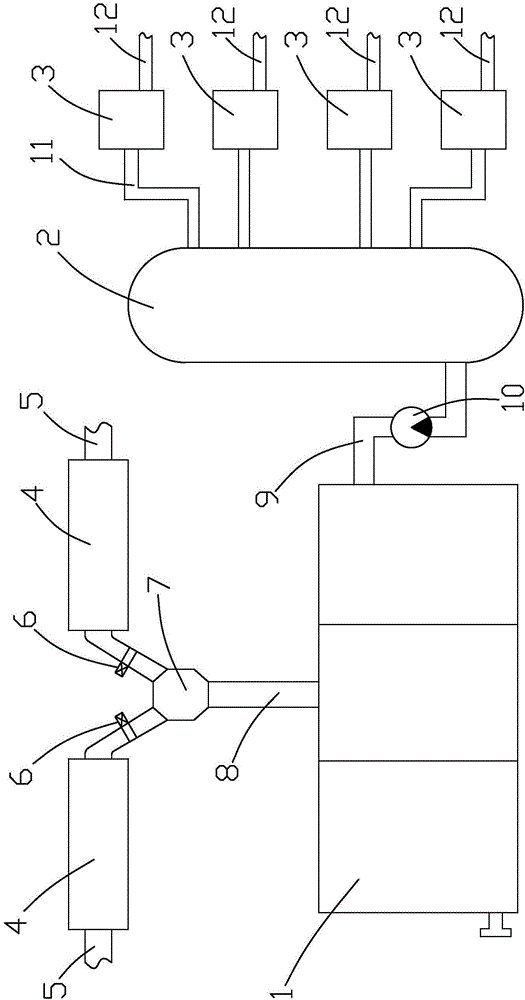

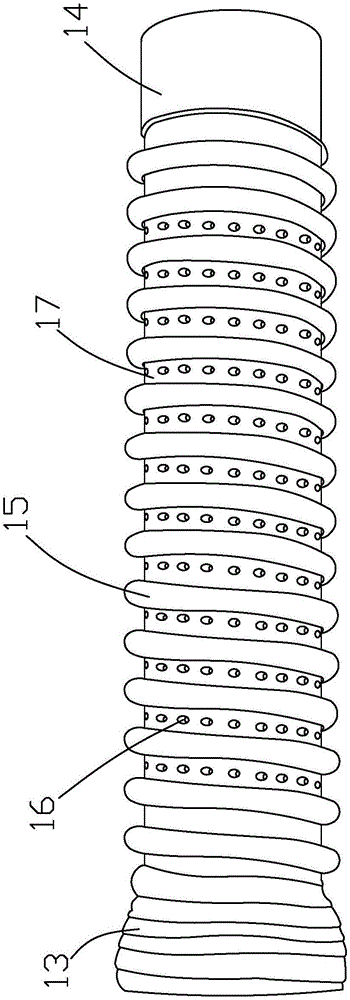

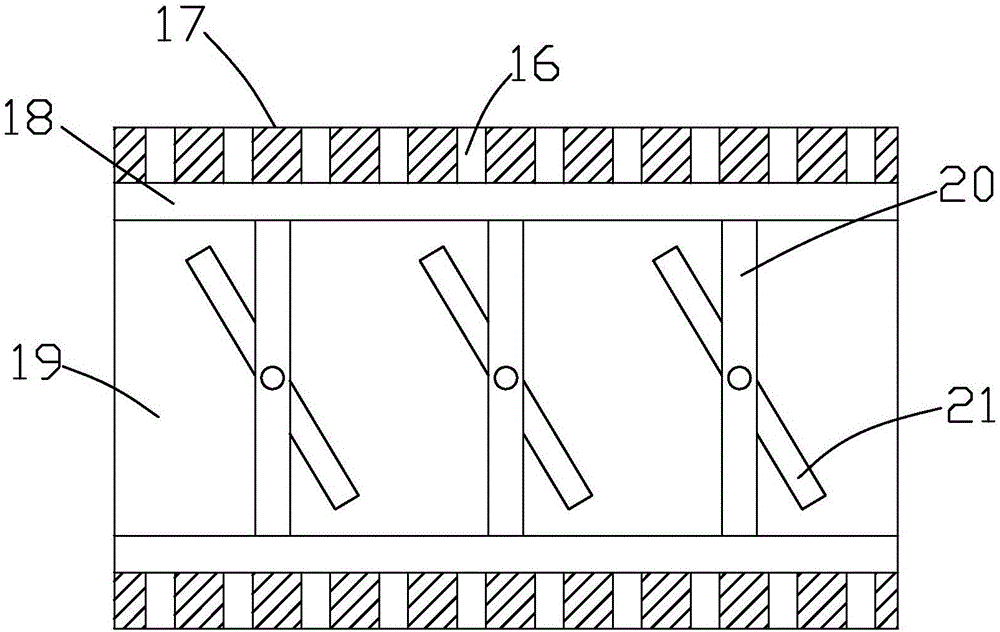

[0047] Such as Figure 1 to Figure 6 As shown, it is a sponge city underground pipe irrigation system of the present invention, comprising seepage pipe 4, regulating and storage box 1, diversion box 2 and booster box 3, seepage pipe 4 is evenly distributed on the diversion pipe 5, seepage pipe 4 It includes a pipe body 17, a sleeve 13 and a threaded joint 14. The sleeve 13 and the threaded joint 14 are respectively fixedly connected to the two ends of the pipe body 17. The pipe body 17 is evenly provided with protective strips 15, and between two adjacent protective strips 15 There are water seepage holes 16 uniformly arranged between them, the inside of the pipe body 17 is provided with a water passage 19, a water seepage film 18 is arranged between the water passage 19 and the water seepage hole 16, a positioning rod 20 is arranged in the water passage 19, and a positioning rod 20 The upper rotation is connected with a unidirectional deflector 21, and a round hole or an oval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com