Continuous production process for quickly cooling vegetables

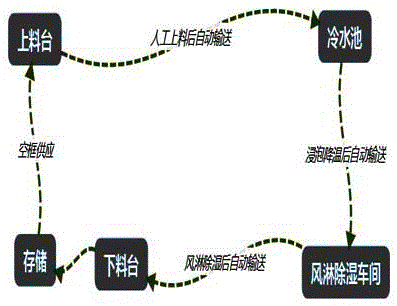

A production process and vegetable technology, applied in the direction of preservation of fruits/vegetables by freezing/refrigeration, etc., can solve the problems of different temperatures, high vegetable dry consumption rate, and high investment in vacuum pre-cooling equipment, and achieve the requirements of less time and process equipment. Simple and effective to ensure the quality of vegetable products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

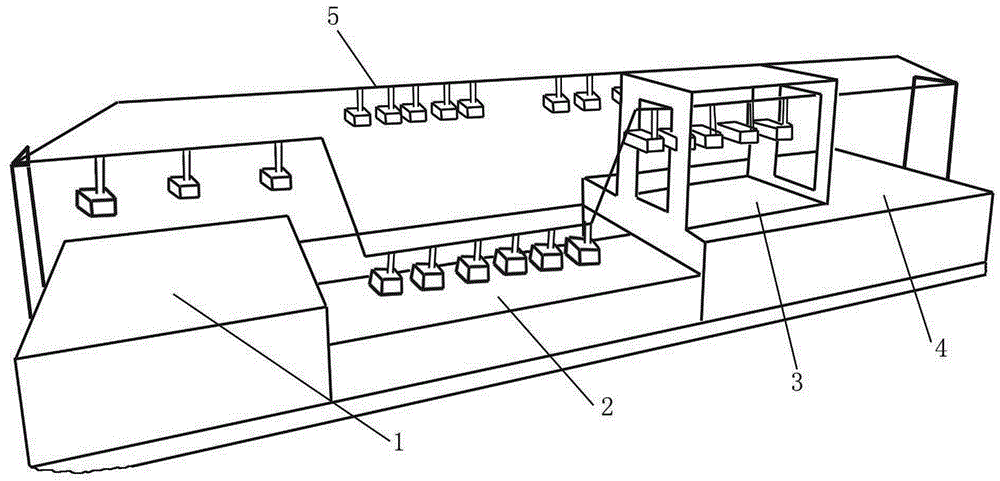

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Chilling celery.

[0028] Harvesting celery: Harvest in the morning on a sunny day, choose the same variety of celery with firm and upright stems, fresh, crisp, tender and firm texture, plump tissue, clean surface, no dirt and foreign pollutants, neat cuts, no bran core, and no damage;

[0029] Basket loading after harvest: put the harvested celery into a clean plastic basket with holes;

[0030] Continuous conveying: the plastic baskets are manually moved to the continuous conveying equipment and fixed, and the equipment automatically conveys the plastic baskets to the cold water pool continuously;

[0031] Soaking and cooling: Soak the plastic basket with celery in the cold water pool for 2 minutes, so that the celery can quickly reach the condition of the central temperature of 2±1°C. The technological conditions of the cold water pool are: 0°C~4°C ice-water mixture made of clean water The ice-water mixture used in the present invention itself has certain...

Embodiment 2

[0035] Embodiment 2: refrigerated lettuce.

[0036] Harvesting lettuce: harvest in the morning on a sunny day, choose the same variety of lettuce that is bright and light green in color, with sufficient moisture, crisp and thin leaves, and can be erected and straight;

[0037] Basket loading after harvest: put the harvested lettuce into a clean plastic basket with holes;

[0038] Continuous conveying: the plastic baskets are manually moved to the continuous conveying equipment and fixed, and the equipment automatically conveys the plastic baskets to the cold water pool continuously;

[0039] Soaking and cooling: Soak the plastic basket with lettuce in the cold water pool for 1.5 minutes, so that the lettuce can quickly reach the condition of the center temperature of 2±1°C. The technological conditions of the cold water pool are: 0°C~4°C made of clean water Ice-water mixture; the ice-water mixture used in the present invention has a certain fluidity, and has the characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com