Environmentally friendly organic fertilizer fermenting technology

A technology of organic fertilizer and fermentation process, applied in the directions of organic fertilizer, inorganic fertilizer, ammonium salt fertilizer, etc., can solve the problems of long fermentation cycle, strong smell of fermentation fertilizer, inability to effectively remove livestock manure, etc. The effect of enhancing fertilizer efficiency and good soil remediation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

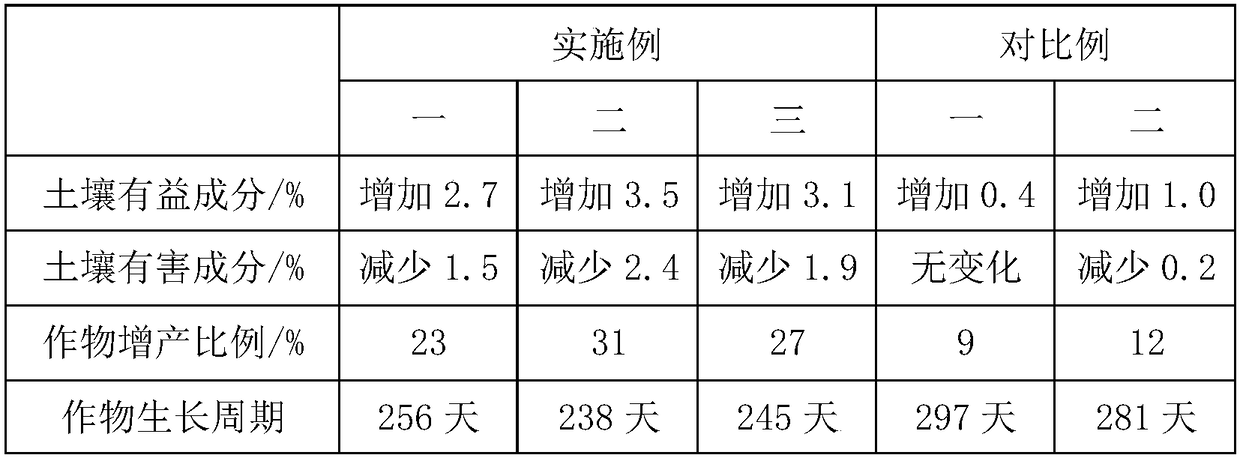

Examples

Embodiment 1

[0022] A kind of environment-friendly organic fertilizer fermentation process that the present invention proposes comprises the following steps:

[0023] S1. Add 80 parts by weight of poultry manure and 20 parts by weight of pond mud to the fermenter, control the water content to 43%, add 18 parts by weight of activated carbon and 10 parts by weight of zinc carbonate, and stir and mix for 8 minutes at a speed of 400r / min. Afterwards, heat up to 68°C, add 3 parts by weight of fermentation bacteria, keep warm and stir until the mixture is evenly mixed to obtain Mixture A;

[0024] S2, leave the mixture A to ferment, during the fermentation process, stir once every 1d, stir for 1h each time, complete the fermentation after the fifth stirring, and obtain the fermentation material B;

[0025] S3. Mix fermented material B, 20 parts by weight of tea dregs and 20 parts by weight of traditional Chinese medicine dregs, and then add them together to a vacuum dryer, and dry until the wate...

Embodiment 2

[0033] A kind of environment-friendly organic fertilizer fermentation process that the present invention proposes comprises the following steps:

[0034] S1. Add 90 parts by weight of poultry manure and 25 parts by weight of pond mud to the fermenter, control the water content to 46%, add 20 parts by weight of activated carbon and 13 parts by weight of zinc carbonate, and stir and mix at a speed of 500r / min for 12min Afterwards, heat up to 72°C, add 5 parts by weight of fermentation bacteria, keep warm and stir until the mixture is evenly mixed to obtain Mixture A;

[0035] S2. Leave the mixture A to stand for fermentation. During the fermentation process, stir once every 1.5 days for 1.5 hours each time. After the fifth stirring, the fermentation is completed, and the fermentation material B is obtained;

[0036] S3. Mix fermented material B, 25 parts by weight of tea dregs and 25 parts by weight of traditional Chinese medicine dregs, and then add them together into a vacuum ...

Embodiment 3

[0044] A kind of environment-friendly organic fertilizer fermentation process that the present invention proposes comprises the following steps:

[0045] S1. Add 100 parts by weight of poultry manure and 30 parts by weight of pond mud to the fermenter, control the water content to 49%, add 22 parts by weight of activated carbon and 15 parts by weight of zinc carbonate, and stir and mix at a speed of 600r / min for 15min Afterwards, heat up to 78°C, add 8 parts by weight of fermentation bacteria, keep warm and stir until the mixture is evenly mixed to obtain Mixture A;

[0046] S2, leave the mixture A to ferment, during the fermentation process, stir once every 2 days, stir for 2 hours each time, complete the fermentation after the fifth stirring, and obtain the fermentation material B;

[0047] S3. Mix fermented material B, 30 parts by weight of tea dregs and 30 parts by weight of traditional Chinese medicine dregs, and then add them together to a vacuum dryer, and dry until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com