Automatic trigger type fire extinguisher

An automatic triggering and fire extinguisher technology, applied in fire rescue and other directions, can solve problems such as failure to burst in time, failure to put out burning points in time, failure to put out fire in time, etc., and achieves low manufacturing and use costs, easy to popularize, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

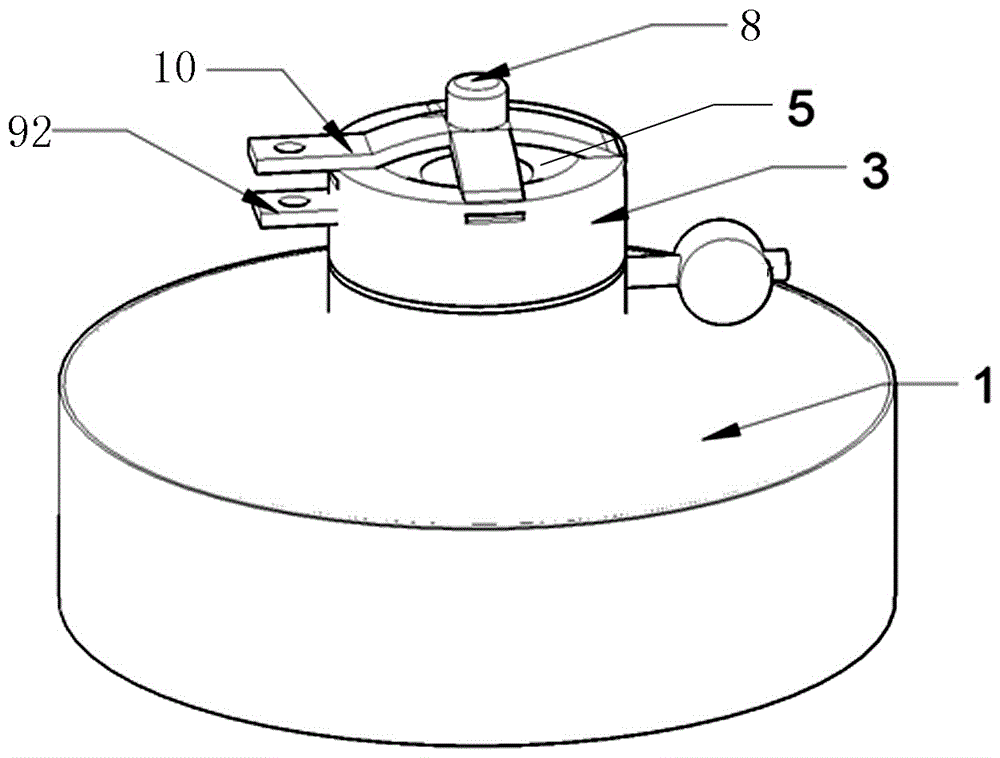

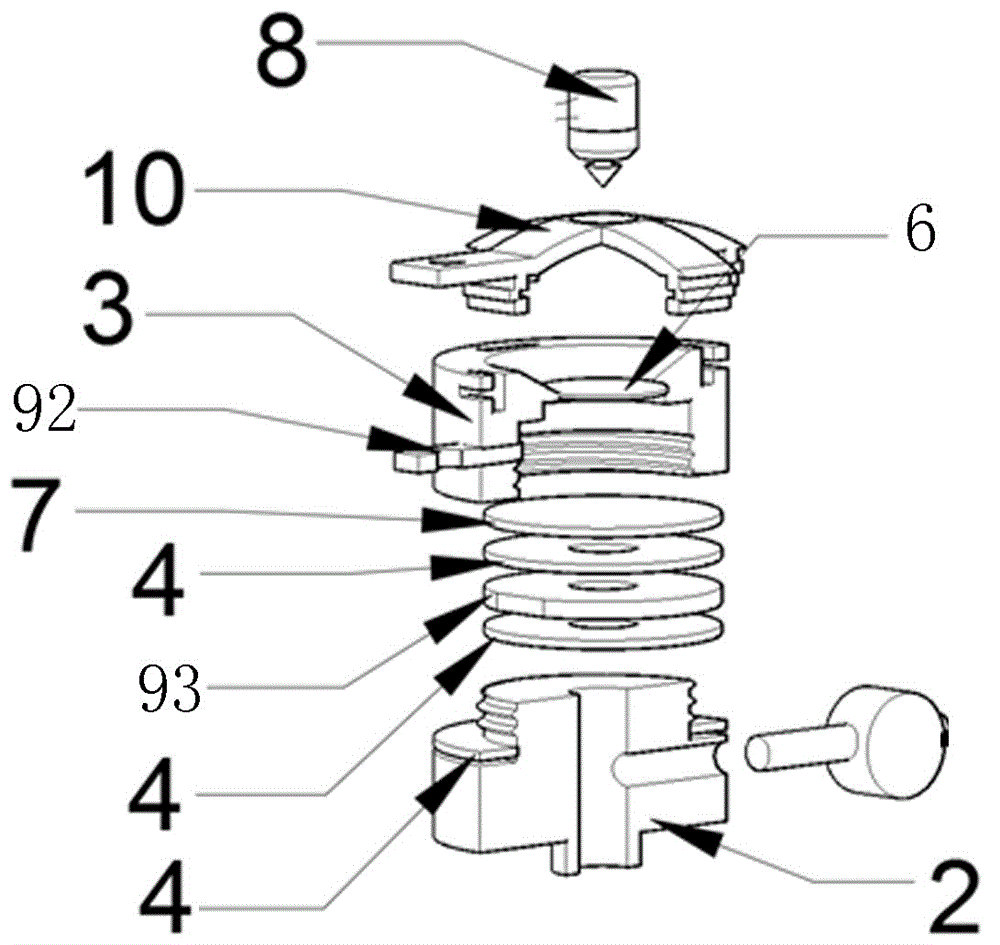

[0027] like figure 1 , figure 2 As shown, in the case of direct contact with the burning point, the membrane rupture device is a sealing pressure-resistant film 7, and the sealing pressure-resistant film is arranged between the sealing film and the sealing component, and is made of heated combustible metal.

[0028] Utilizing the phenomenon that combustible metals burn when heated, the sealing film is burned through by burning, and the fire extinguishing material stored in the pressure vessel can be ejected from the top of the ceramic cap to realize automatic triggering.

[0029] Further, the sealing pressure-resistant film is made of metal such as magnesium sheet, or magnesium alloy sheet, or conductive titanium powder compressed sheet, or titanium sheet, or titanium alloy sheet, or aluminum sheet, or tin sheet. The best solution is magnesium flakes. 38°C-40°C is the ignition point of magnesium. Magnesium can burn in carbon dioxide. The metal strength is similar to gold and...

Embodiment 2

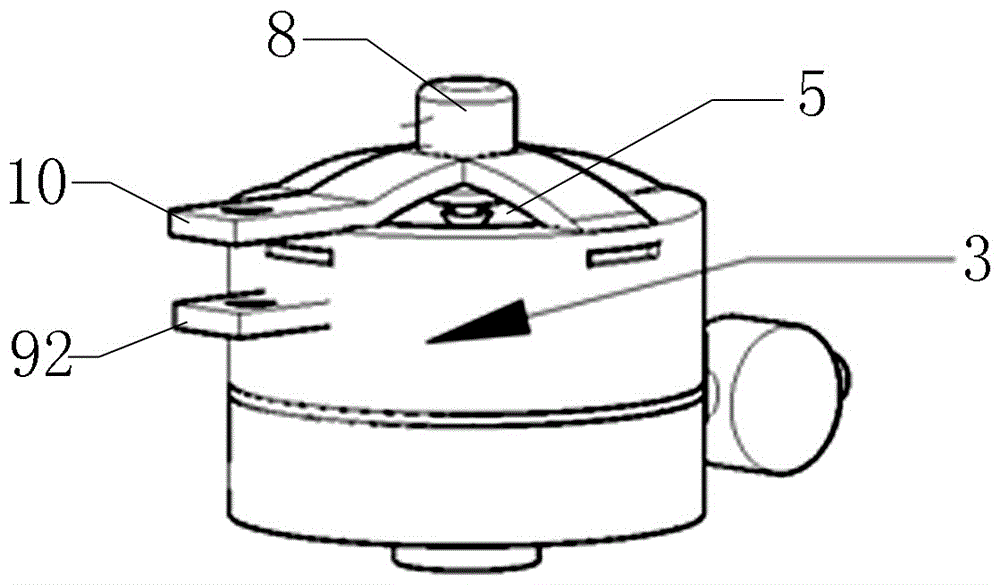

[0032] like Figure 1 to Figure 5 As shown, in the case of direct contact with or relatively close to the burning point, the membrane rupture device can also be a temperature-sensitive puncturing assembly 8, which includes a heat-deformed deformed metal part 81 and an acupuncture part 82; The acupuncture part points to and is close to the sealing film, the top of the acupuncture part is detachably connected to the bottom of the deformed metal part, and the deformed metal part is fixed by a metal bracket arranged on the top of the spout; the deformed metal part can be A deforming movement is generated towards the sealing film, and the needling part is able to pierce the sealing film.

[0033] Among them, after the deformed metal part is heated, it is blocked by the metal bracket and moves toward the deformation of the sealing film. The acupuncture part connected with the deformed metal part begins to move towards the sealing film and finally pierces the sealing film; the sealin...

Embodiment 3

[0039] On the basis of the foregoing embodiment 2, as Figure 1 to Figure 5 As shown, this embodiment proposes an improved technical solution.

[0040] The membrane breaking device is a temperature-sensitive puncturing component with a temperature control circuit; the temperature control circuit is connected to both ends of the deformable metal part through two wires; the deformable metal part is energized to generate heat and can generate deformation movement to the sealing film, The needling parts are able to pierce the sealing membrane.

[0041] When the flame burns, the heat or smoke rises upwards, but the horizontal temperature control diffusion or smoke diffusion is slow; if the fire extinguishing equipment is set in parallel with the burning point, at this time, the temperature control circuit set above the burning point can be used to detect the presence of fire. At the burning point, the power frequency voltage is controlled by the temperature control circuit to cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com