Integrated cleaning device for power equipment flashover prevention

A technology for power equipment and cleaning devices, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, and cleaning methods using tools, etc., which can solve problems such as personal health injuries, easy to scrub dead ends, and high fatigue intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

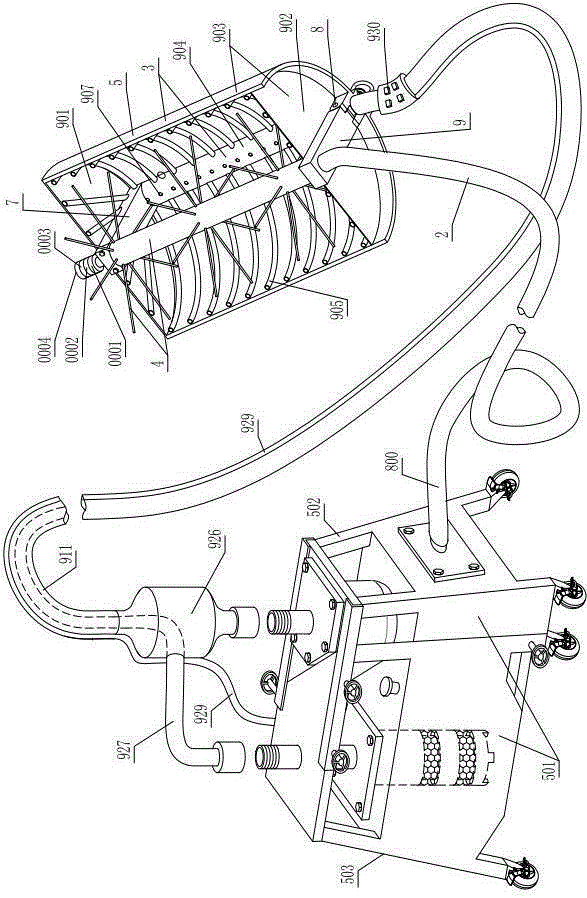

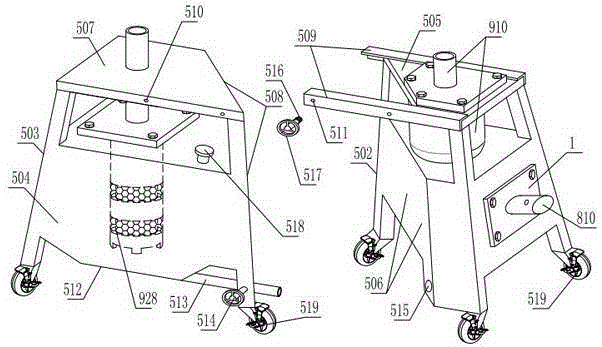

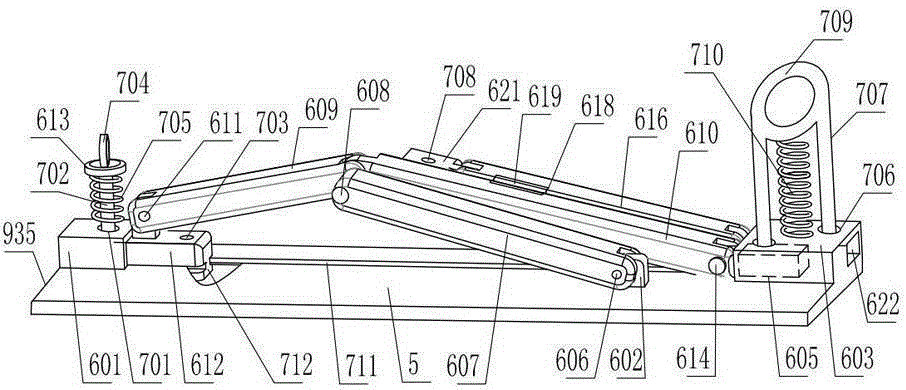

[0028] As shown in the figure, the integrated power equipment anti-flashover cleaning device includes a cleaning head 3 driven by a power unit 1 through a transmission hose 2. The cleaning head includes a vertically arranged rotating brush 4, and one side of the rotating brush is covered. There is a protective cover 5 with a C-shaped cross section, a handle 6 is fixed on the outside of the protective cover, and a horizontally extending upper rod 7 is fixed on the inner upper end of the protective cover. The end of the upper rod can only be rotated with the upper end of the rotary brush through the upper connecting device. , the lower end of the protective cover inner side is hinged with the lower rod 9 that can swing up and down through the horizontal shaft 8, the lower rod is rotated and matched with the lower end of the rotating brush through the lower connecting device, and the lower rod is also inserted and matched with the lower end of the rotating brush through the lower c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com