Magnetic coupling rodless cylinder transmission cutting film device

A rodless cylinder and membrane device technology, which is applied in welding equipment, laser welding equipment, metal processing, etc., can solve the problems of film waste, film cutting edge, easy to be scratched, plate surface damage, etc., to reduce the occupied length , Reduce power consumption and occupy a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

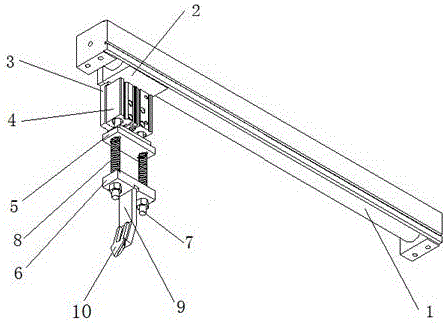

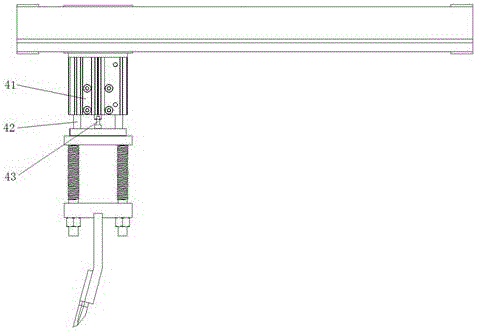

[0021] like figure 1 and figure 2 As shown, a magnetically coupled rodless cylinder transmission film cutting device includes a horizontally magnetically coupled rodless cylinder 1 on which a cylinder slide 2 is slidably installed, and also includes a T-shaped fixing plate 3. Vertical movement cylinder 4, screw rod 7, first cylinder fixed plate 5, second cylinder fixed plate 6, spring 8, film cutting knife rest 9 and film cutting knife 10, described vertical movement cylinder 4 passes T-shaped The fixed plate 3 is vertically installed below the cylinder slide table 2, and the vertical motion cylinder 4 includes a cylinder block 41, a push rod 43 positioned at the bottom center of the vertical motion cylinder block and a piston rod 42 positioned at the bottom two ends of the vertical motion cylinder block , the push rod 43 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com