Cutting method and application method of high-temperature protective film for bonding

A cutting method and technology of protective film, applied in laser welding equipment, electrical components, circuits, etc., can solve the problems of inability to grasp the size, difficulty, reduce the UPH of the machine, etc. The effect of quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means of the present invention and the technical effects that can be achieved more clearly and more completely disclosed, an embodiment is provided hereby, and the following detailed description is given in conjunction with the accompanying drawings:

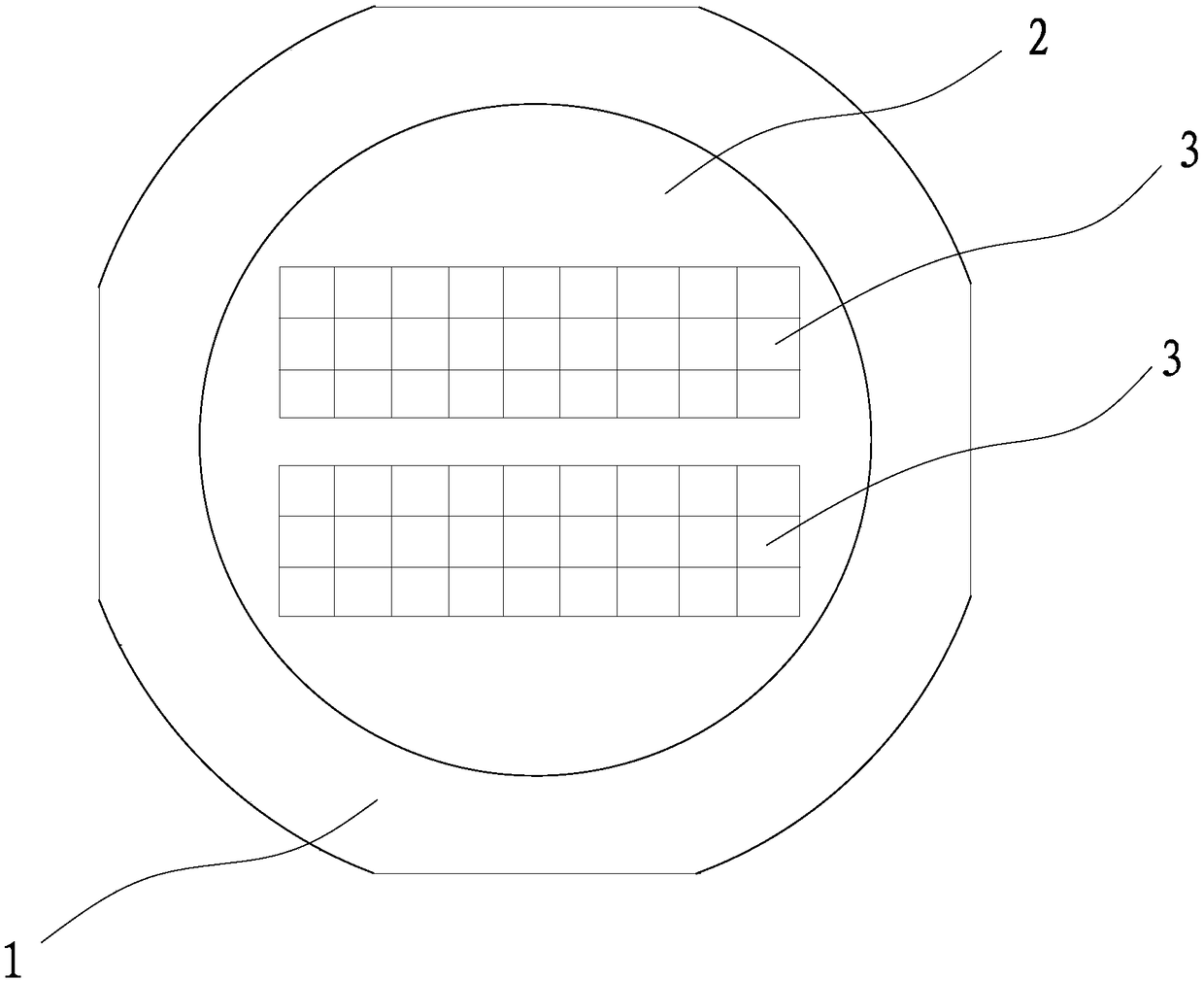

[0034] Such as figure 1 as shown, figure 1 It is a schematic diagram of the combination of the high-temperature protective film 3, the blue film 2 and the thin iron plate 1 after cutting by the cutting method of the present invention. A cutting method of the high-temperature protective film 3 for bonding in this embodiment includes the following steps:

[0035] Step (1) Prepare a flat thin iron plate 1;

[0036] Step (2) Paste the blue film 2 for scribing on the thin iron plate 1 evenly;

[0037] Step (3) Attach the high temperature protective film 3 to be cut evenly on the blue film 2 for scribing;

[0038] Step (4) Place the thin iron plate 1 with the blue film 2 and the high temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com