Hobbing cutting self-lubricating tool suitable for machining energetic materials

A mechanical processing and self-lubricating technology, applied in metal processing and other directions, can solve the problems of long implementation cycle of new technologies and new processes, lengthy cutting and dissection process chains, and high development or transformation costs, so as to improve surface processing quality and product quality. Consistent quality, low cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings.

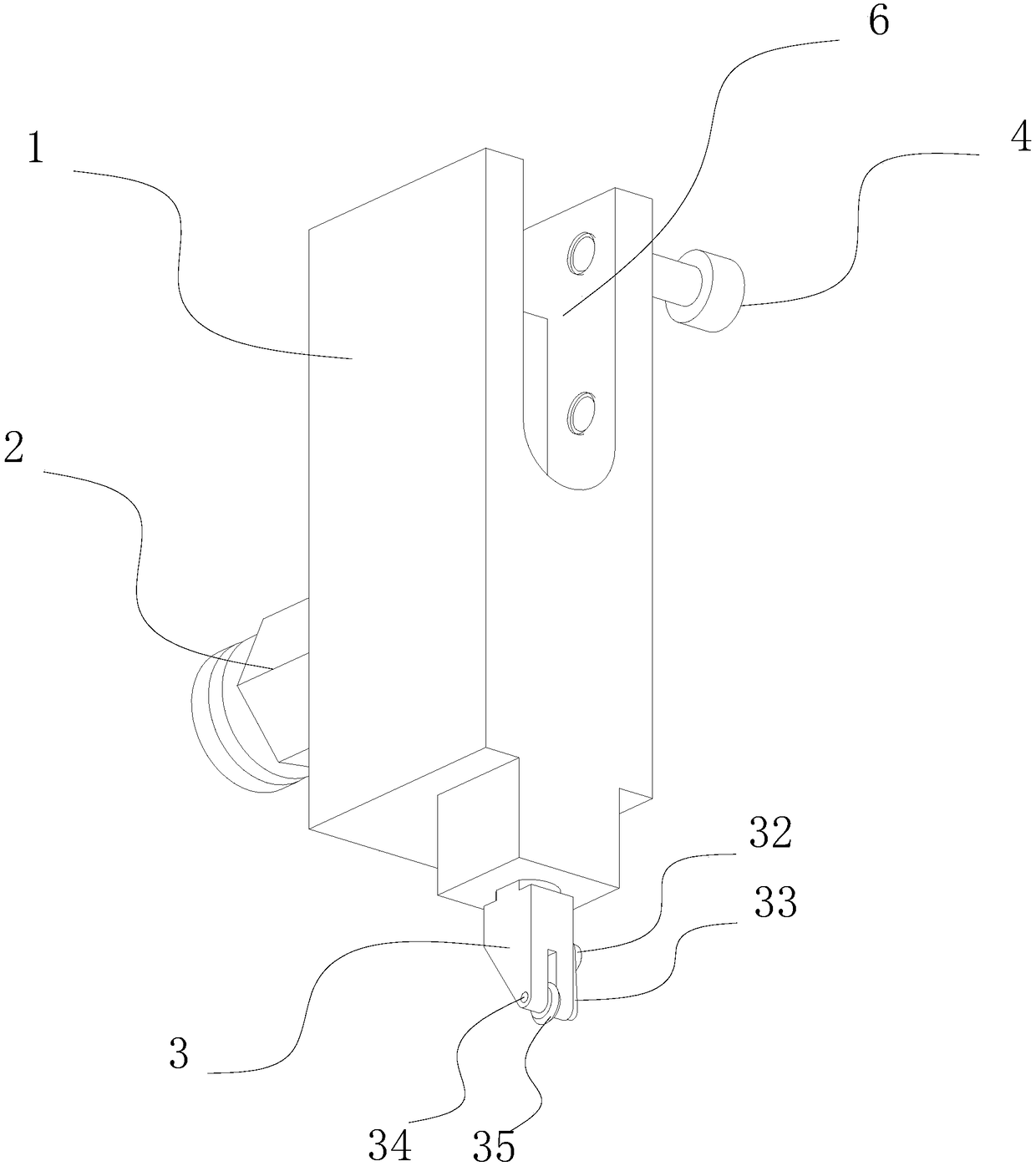

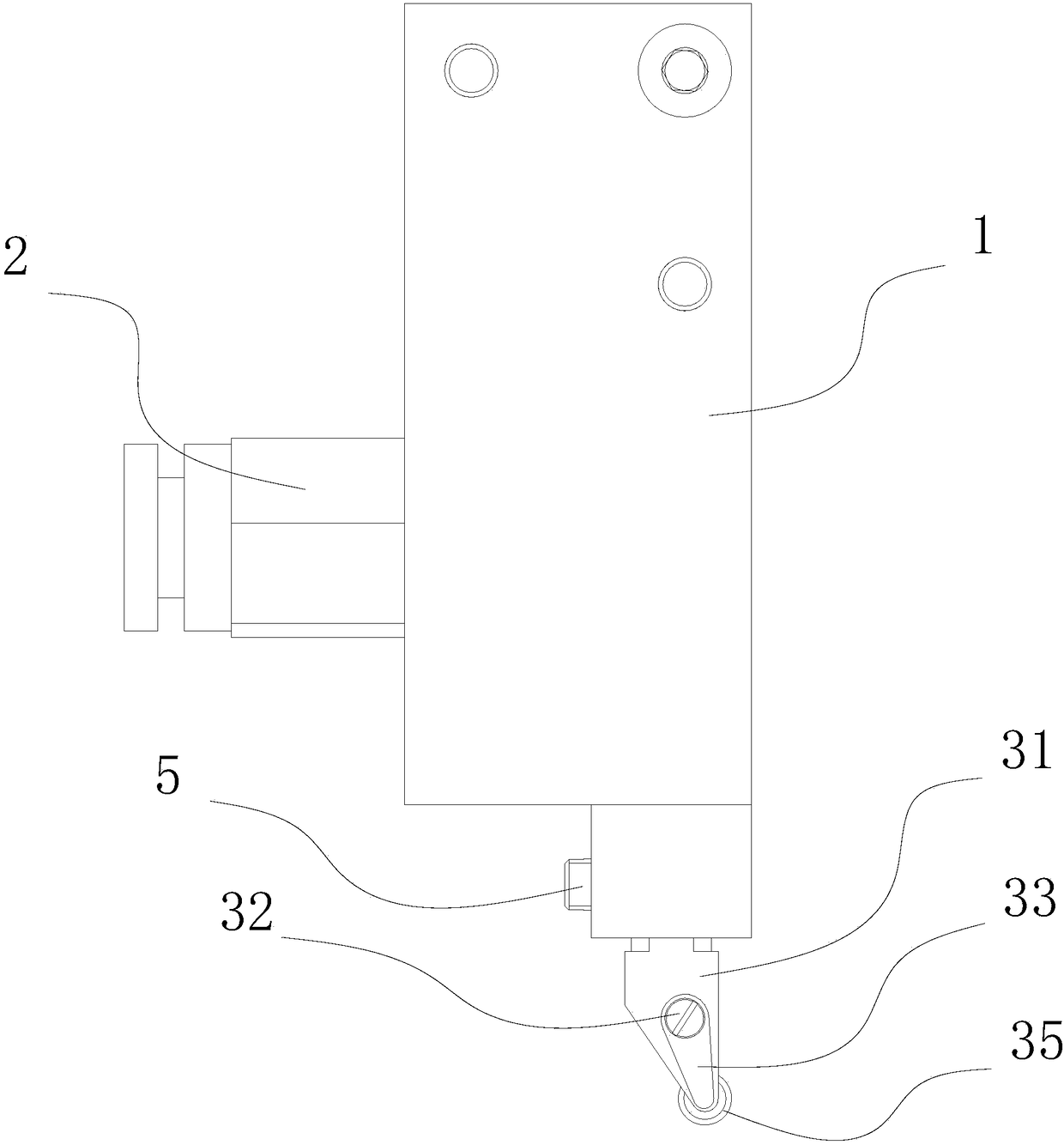

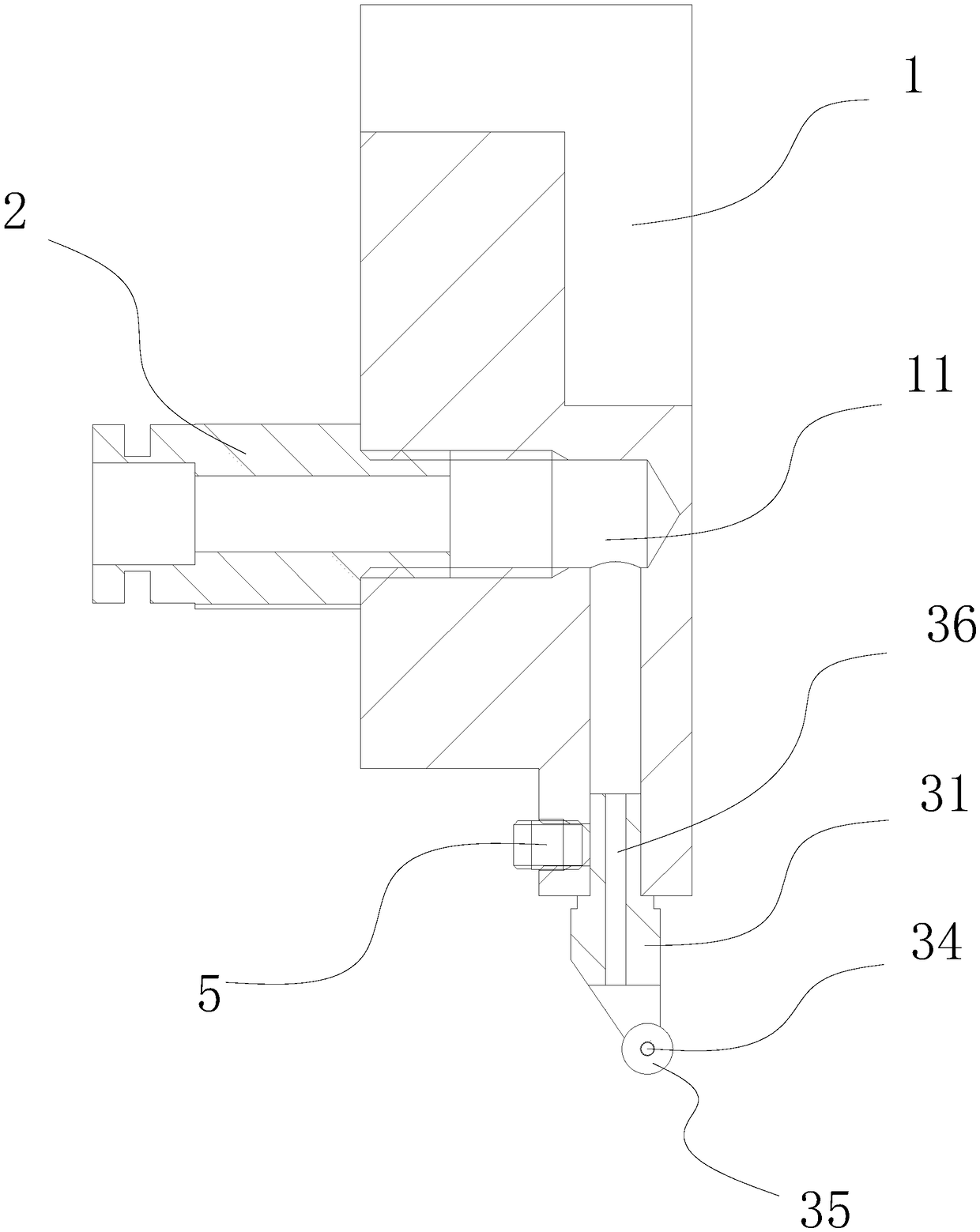

[0028] like Figure 1-3The hobbing self-lubricating tool suitable for machining energetic materials shown includes a hob bar 1, and one end of the hob bar 1 is provided with a positioning hole, and a hob head 3 is installed in the positioning hole. A pipe joint 2 is installed on one side of the hob rod 1 , and a cutting fluid pipeline 11 is arranged inside the raceway rod 1 , and one end of the cutting fluid pipeline 11 communicates with the pipe joint 2 and the other end communicates with the hob head 3 . The hob head 3 includes a hob frame 31, the upper end of the hob frame 31 is fixedly installed in the positioning hole through the top wire 5, the hob shaft 34 is installed at the lower end of the hob frame 31, and the hob shaft 34 A hob blade 35 is installed on it, and a pressure plate 33 is installed on one side of the hob frame 31 through a set screw 32. The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com