Intelligent packaging line

An intelligent packaging and assembly line technology, applied in packaging, packaging machines, transportation packaging, etc., can solve the problems of inability to meet the barcode traceability of multiple production lines, no barcode scanning and identification function, and large conveying capacity of conveyors. Inspection efficiency, save production time, and facilitate traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

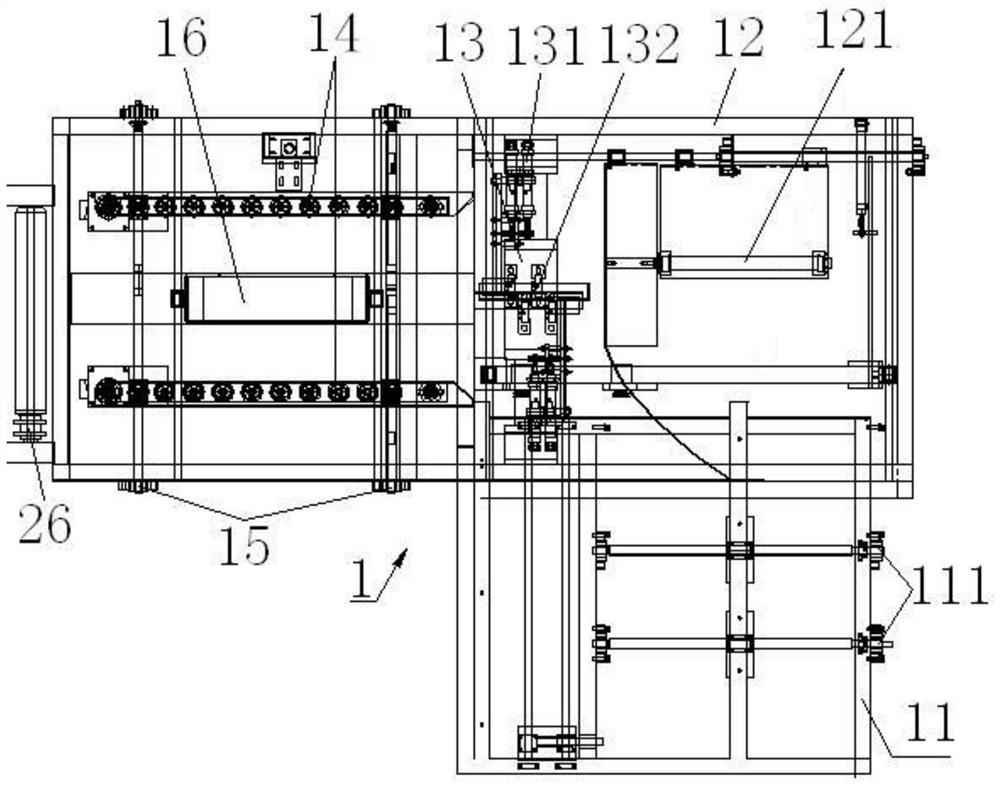

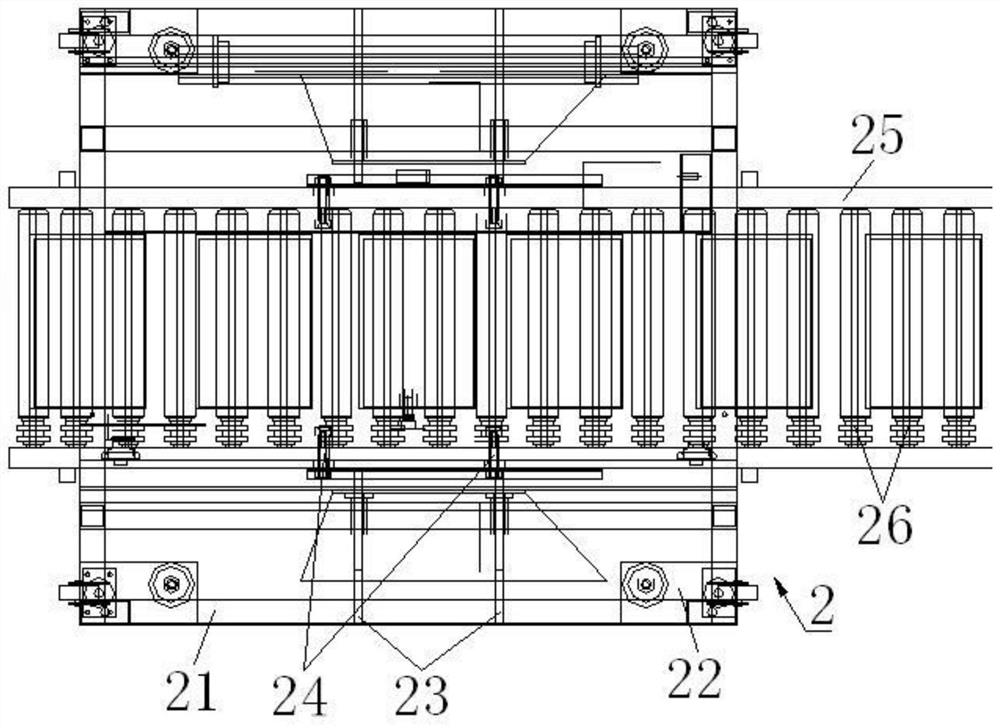

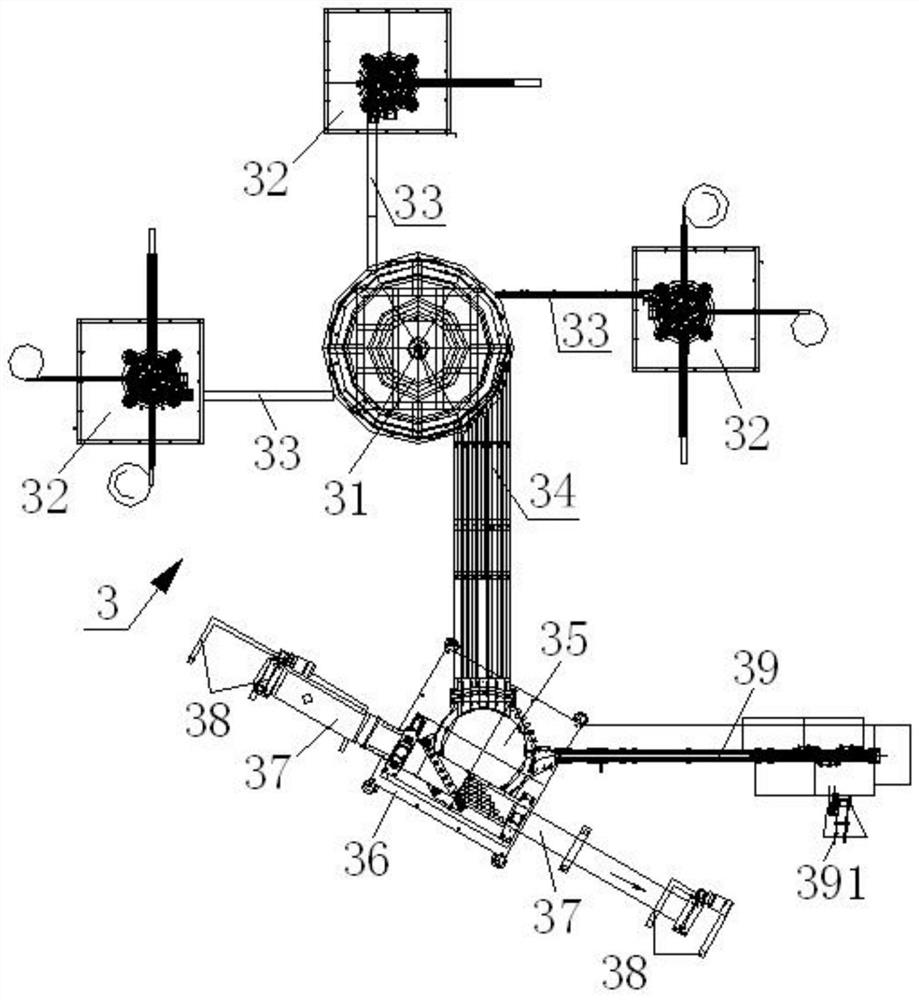

[0022] see Figures 1 to 7 , intelligent packaging line, including automatic unpacking mechanism 1, automatic bagging mechanism 2, product conveying mechanism 3, carton diversion supply double-layer conveying mechanism 4, automatic sealing bag sealing mechanism 5, automatic sealing mechanism 6, automatic winding machine 7, The automatic unpacking mechanism 1 and the automatic bagging mechanism 2 are installed together. The automatic bagging mechanism 2 is connected to one end of the carton diverting supply double-layer conveying mechanism 4 through a climbing conveyor belt (not shown in the figure), and the product is conveyed. The number of mechanisms 3 is four and is fixedly placed on one side of the carton diverting supply double-layer conveying mechanism 4. The sealing bag automatic sealing mechanism 5 is connected with the other end of the carton diverting supply double-layer conveying mechanism 4. The automatic sealing mechanism 6 It is installed and connected with the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com