Conveying shelf for logistic stacking machine

A conveying rack and logistics code technology, which is applied to the conveying rack field of logistics palletizers, can solve the problems of insufficient order, unstable operation of the manipulator, limited rotation angle and working space, etc., and achieves high work efficiency, not easy to slip off, and stable performance. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical scheme of the present invention is further described below in conjunction with the accompanying drawings of the description:

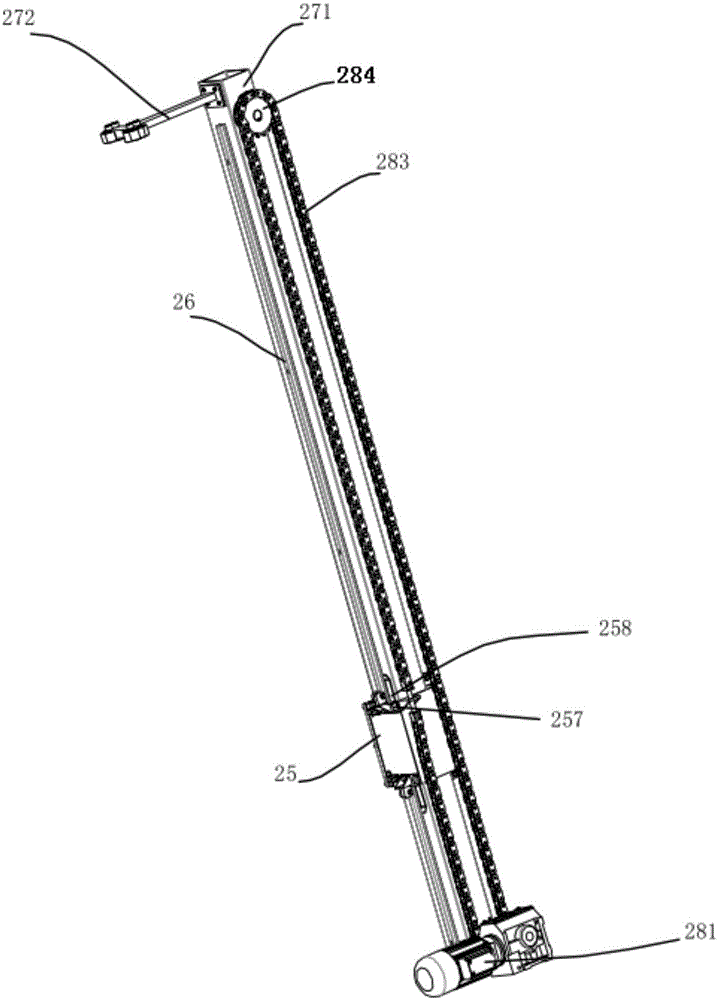

[0035] like Figure 1-13 As shown, the present invention proposes a specific embodiment of a conveying frame applied to a logistics palletizer, such as Image 6 As shown in the figure, the conveying frame applied to the logistics palletizer includes a lateral movement drive device 2 of the cargo conveying platform, an up and down movement drive device 3 of the cargo conveying platform, a limit sensor 258 and a PLC controller, and the limit sensor 258 is connected with the PLC controller. ;

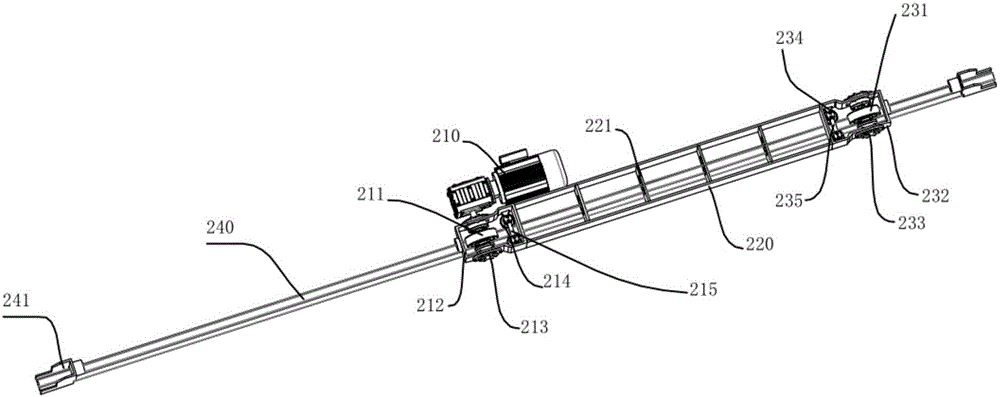

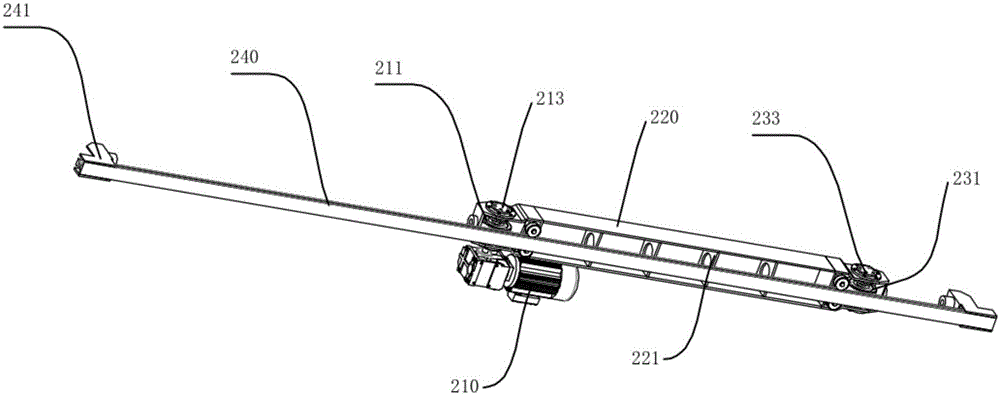

[0036] like figure 1 , figure 2 , Figure 10 and Figure 11As shown, the lateral movement driving device 2 of the goods conveying platform includes a lateral sliding rail 240, a first servo motor 210, a first frame 212, a bracket 220, a second frame 232, a driving roller 211 and a driven roller 231; Both ends of the lateral slide rail 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com