Novel method for chrome tanning wastewater treatment and chrome recycling

A treatment method and wastewater technology, which is applied in animal processing wastewater treatment, water/sludge/sewage treatment, ion exchange water/sewage treatment, etc., can solve the problems of waste of resources, large dosage of chemicals, secondary pollution, etc. Achieve the effects of improving economic benefits, reducing environmental pollution, and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

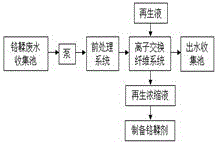

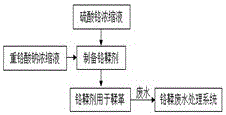

[0019] Treatment methods of chrome tanning wastewater, such as figure 1 As shown, it includes the following steps: the chrome tanning wastewater is homogenized in the collection tank, and then pumped to the pre-treatment system to remove impurities such as hair residue, dander, protein, dyes, etc.; the chrome tanning wastewater after impurity removal enters the ion exchange The fiber system is exchanged and adsorbed, and the total chromium and hexavalent chromium in the effluent meet the standards, which can be reused as flushing water in the tanning process or discharged into the subsequent treatment system to meet the standards; when the ion exchange fiber is saturated, it is regenerated with the regeneration solution. Ion Exchange Fiber Circulation Treatment of Chrome Tanning Wastewater

[0020] The pretreatment system is an impurity remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com