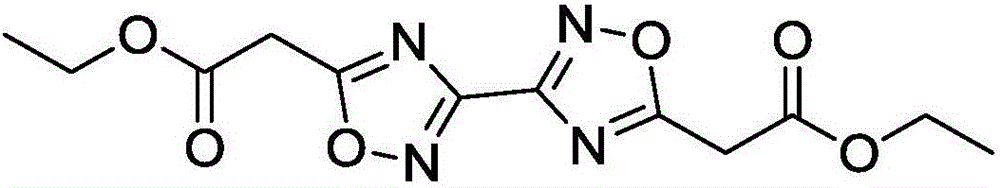

Synthesis method of 5,5'-di(acetic ether)-3,3'-bi-1,2,4-oxadiazole

An ethyl acetate-based, synthetic method technology, applied in organic chemistry and other directions, can solve problems such as poor selectivity and low yield, and achieve the effects of improving selectivity and reducing reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

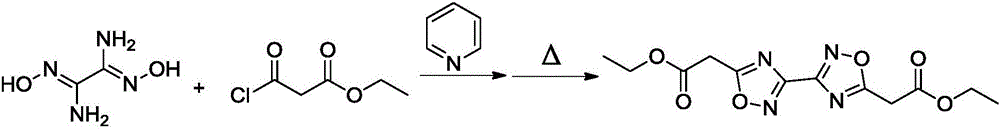

[0021] Example 1 Synthesis of 5,5'-diacetoxyethyl-3,3'-bi-1,2,4-oxadiazole

[0022] (1) Under the condition of 25°C, add 30ml of ethylene glycol dimethyl ether and 1.6g of pyridine into the reaction flask in turn, after stirring evenly, add 1.2g of diaminoglyoxime in batches, stir until completely dissolved, drop Add 3.0 g of ethyl chloroformoacetate, and react at 40°C for 30 min;

[0023] (2) Continue to heat the reaction solution obtained in step (1) to 100°C, and after continuing to react for 2 hours, pour the reaction solution into water, extract with chloroform, dry and distill under reduced pressure to obtain ethyl 5,5′-diacetate Base-3,3'-bi-1,2,4-oxadiazole was 1.92 g, and the yield was 62%.

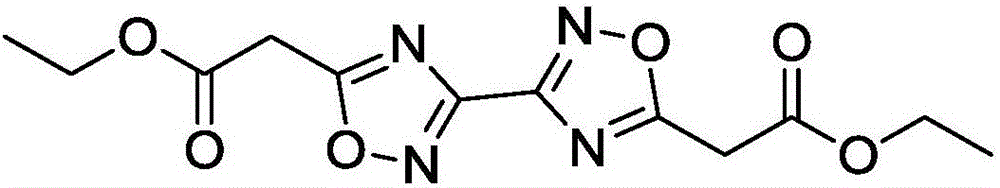

[0024] Structure Identification:

[0025] Elemental analysis:

[0026] Molecular formula: C 12 h 14 N 4 o 6

[0027] Theoretical value: C 46.45, H 4.55, N 18.06;

[0028] Found: C 46.51, H 4.52, N 18.10.

[0029] Infrared (KBr, cm -1 ): 3473, 3376, 3180, 2976, 1751, 16...

Embodiment 2

[0034] (1) Under the condition of 25°C, add 25ml of ethylene glycol dimethyl ether and 0.4g of pyridine into the reaction flask in turn, after stirring evenly, add 1.2g of diaminoglyoxime in batches, stir until completely dissolved, drop Add 1.5 g of ethyl chloroformoacetate, and react at 30°C for 40 minutes;

[0035] (2) Continue to heat the reaction solution obtained in step (1) to 80°C, and after continuing the reaction for 3 hours, pour the reaction solution into water, extract with chloroform, dry and distill under reduced pressure to obtain ethyl 5,5′-diacetate Base-3,3'-bi-1,2,4-oxadiazole 1.86g, yield 60%.

Embodiment 3

[0037] (1) Under the condition of 25°C, add 40ml of ethylene glycol dimethyl ether and 2.0g of pyridine into the reaction flask in turn, after stirring evenly, add 1.2g of diaminoglyoxime in batches, stir until completely dissolved, drop Add 4.5 g of ethyl chloroformoacetate, and react at 40°C for 20 min;

[0038] (2) Continue to heat the reaction solution obtained in step (1) to 100°C, and after continuing to react for 2 hours, pour the reaction solution into water, extract with chloroform, dry and distill under reduced pressure to obtain ethyl 5,5′-diacetate Base-3,3'-bi-1,2,4-oxadiazole was 1.92 g, and the yield was 62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com