Method for preparing nano-catalyst by using platinum group metal in waste gas treatment catalyst

A technology of nano-catalysts and platinum group metals, applied in metal processing equipment, nanotechnology for materials and surface science, nanotechnology, etc., to achieve the effects of simple devices, reduced production costs, and low-cost preparation of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

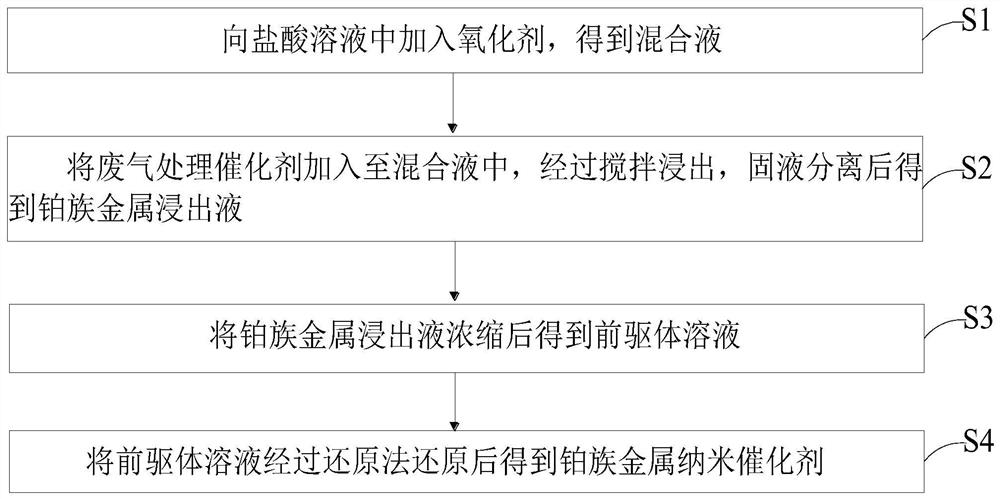

[0052] A method for preparing nano-catalysts using platinum group metals in exhaust gas treatment catalysts, comprising the following steps:

[0053] S1. Add an oxidant to the hydrochloric acid solution to obtain a mixed solution; wherein the volume of the mixed solution is 1 L, the concentration of the mixed solution hydrochloric acid is 5mol / L, the oxidant is hydrogen peroxide, and the mass concentration of the hydrogen peroxide in the mixed solution is 5%;

[0054] S2, the Pt-Rh type automobile exhaust treatment catalyst (the mass content of Rh in this catalyst is relatively low, and the mass content of Rh is only 1 / 15~1 / 20 of the mass content of Pt) is crushed and ground until the particle size is 100 mesh , and set aside; then 100 g of the ground exhaust gas treatment catalyst was added to the mixed solution and stirred at 25° C. for 6 hours, and the platinum group metal leach solution was obtained after solid-liquid separation, wherein the leaching rate of Pt was 96.62%, ...

Embodiment 2

[0064] A method for preparing nano-catalysts using platinum group metals in exhaust gas treatment catalysts, comprising the following steps:

[0065] S1, add oxidant to hydrochloric acid solution, obtain mixed solution; Wherein the volume of mixed solution is 500mL, the concentration of mixed solution hydrochloric acid is 9mol / L, oxidant is sodium hypochlorite, and the molar concentration of sodium hypochlorite in mixed solution is 0.1mol / L;

[0066] S2, breaking and grinding the Pd-Rh type automobile exhaust gas treatment catalyst (the mass content of Rh in the catalyst is relatively low, and the mass content of Rh is only 1 / 15 to 1 / 20 of the mass content of Pd) and ground until the particle size is 100 mesh , set aside; then 100g of the ground waste gas treatment catalyst was added to the mixed solution and stirred at 25°C for 6h, and the platinum group metal leachate was obtained after solid-liquid separation, wherein the leaching rate of Pt was 97.30%, and the leaching rate...

Embodiment 3

[0073] A method for preparing nano-catalysts using platinum group metals in exhaust gas treatment catalysts, comprising the following steps:

[0074] S1, add oxidant to hydrochloric acid solution, obtain mixed solution; Wherein the volume of mixed solution is 2L, the concentration of mixed solution hydrochloric acid is 7mol / L, oxidant is chlorine, and the concentration of chlorine in mixed solution is 0.05 mole per liter;

[0075] S2. Crush and grind the waste gas treatment catalyst Pt-Pd metal industrial waste gas catalyst to a particle size of 100 mesh, and set aside; then add 100g of the ground waste gas treatment catalyst to the mixed solution and stir at 25°C for 8 hours, and separate the solid and liquid Finally, a platinum group metal leaching solution was obtained, wherein the Pt leaching rate was 95.41%, and the Pd leaching rate was 97.85%;

[0076] S3, evaporating and concentrating the leach solution of platinum group metals to obtain a precursor solution of platinum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com