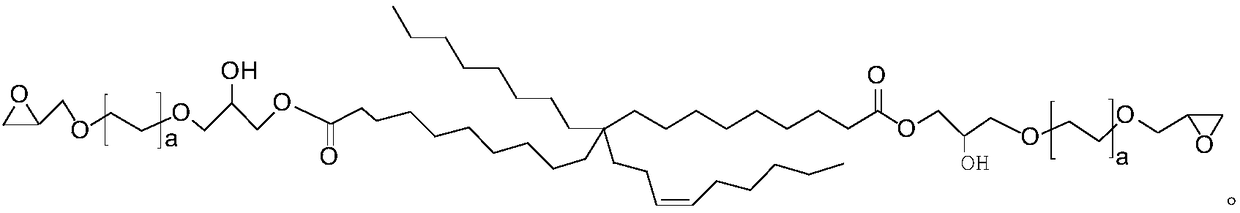

A kind of dimer acid modified epoxy resin and preparation method thereof

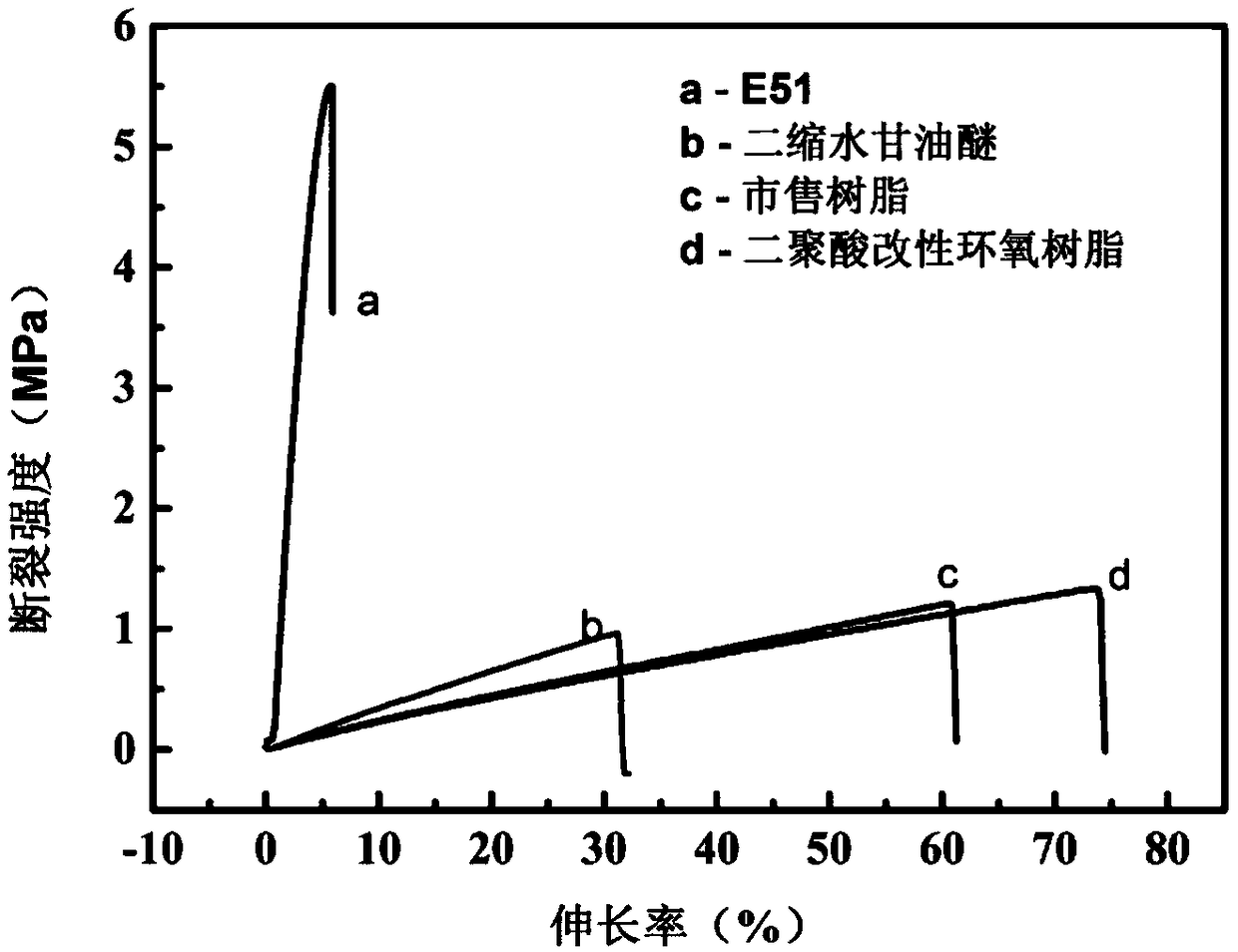

A technology of epoxy resin and dimer acid, which is applied in organic chemistry, coating, etc., can solve the problems of poor toughness, low reactivity, and difficult film formation of epoxy resin, so as to reduce the rigid structure of resin and solve the problem of excessive viscosity , the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

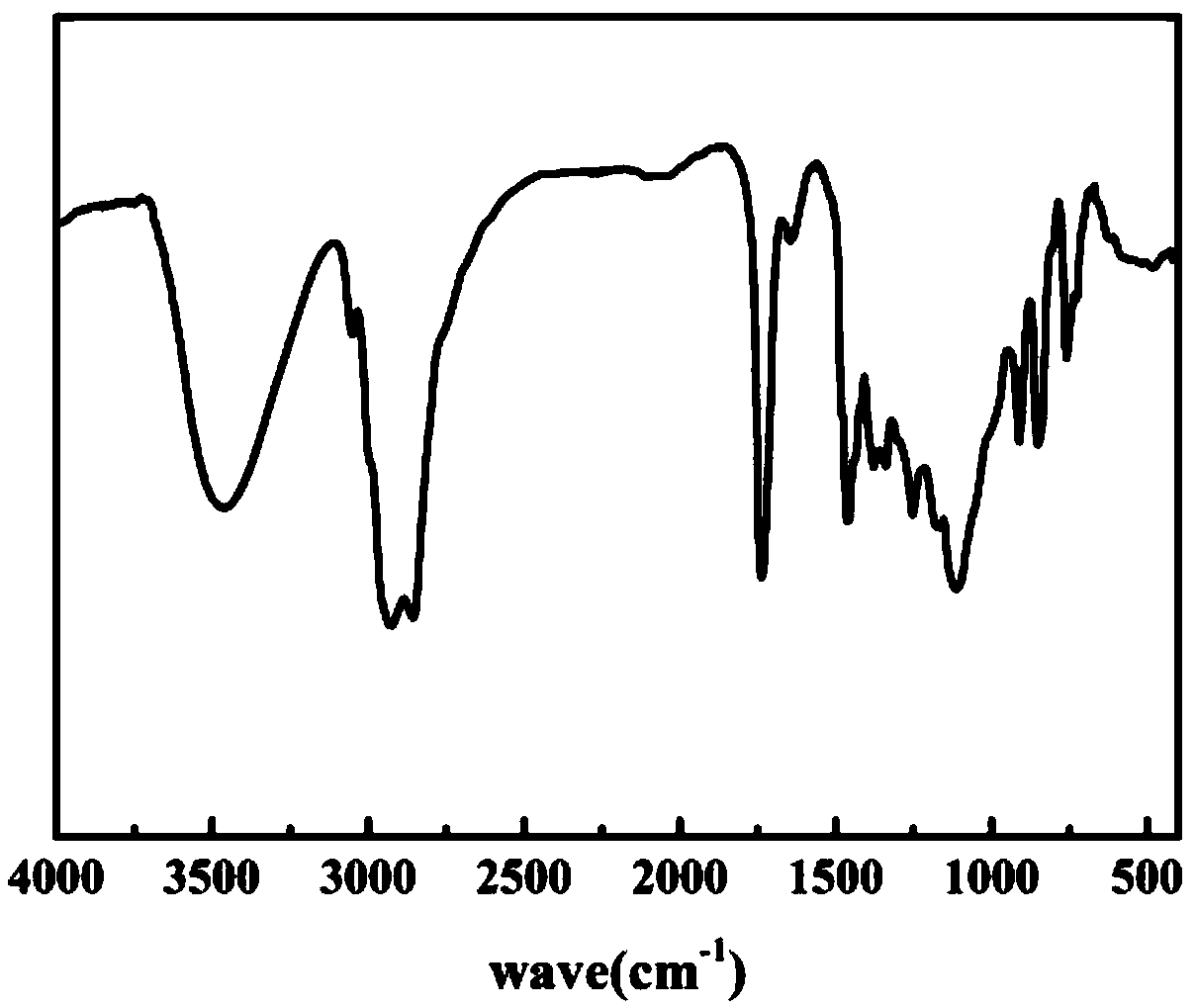

Method used

Image

Examples

Embodiment 1

[0036] Add 34.36g of 1,4-butanediol diglycidyl ether and 25.10g of dimer acid to a 250ml four-neck flask, blow nitrogen into it and stir for 0.5h, raise the temperature to 100°C, weigh the dimer acid and aliphatic dimer acid The tetrabutylammonium bromide catalyst with a total weight of 0.15wt% of glycerol ether was dissolved in 1.5mL of acetone, and after dissolving, it was added to a four-necked flask, and the temperature was continued to rise to 120°C, and the reaction was kept for 6.0h. The acid value was tested to be 1.5mgKOH / g, the epoxy value is 0.42; stop the insulation reaction, cool to room temperature, and discharge.

Embodiment 2

[0038] Add 38.23g of 1,6-hexanediol diglycidyl ether and 25.10g of dimer acid into a 250ml four-neck flask, blow nitrogen into it and stir for 0.5h, raise the temperature to 100°C, weigh the dimer acid and aliphatic dimer acid The dodecyltrimethylammonium chloride catalyst with a total weight of 0.15wt% of glycerol ether was dissolved in 1.5mL of acetone, and added to a four-neck flask after dissolving, and continued to heat up to 120°C, and kept the temperature for 6.0h. After testing the acid value It is 1.6mgKOH / g, and the epoxy value is 0.40; stop the insulation reaction, cool to room temperature, and discharge.

Embodiment 3

[0040] Add 30.58g of 1,4-butanediol diglycidyl ether and 25.10g of dimer acid to a 250ml four-neck flask, blow in nitrogen and stir for 0.5h, heat up to 100°C, weigh dimer acid and aliphatic dimer acid A tetrabutylammonium bromide catalyst with a total weight of 0.20wt% of glycerol ether was dissolved in 2.0mL of acetone, and after dissolving, it was added to a four-neck flask, and the temperature was continued to rise to 120°C, and the temperature was kept for 6.5h. g, the epoxy value is 0.35; stop the insulation reaction, cool to room temperature, and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com