High-permeability and high-temperature-resistant type acrylate pressure-sensitive adhesive and preparation method thereof

A high-temperature-resistant, acrylate technology, applied in pressure-sensitive films/sheets, adhesives, adhesive types, etc., can solve problems such as softening, poor heat resistance, and inability to use normally, achieve high permeability, peel off, etc. Strong force and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

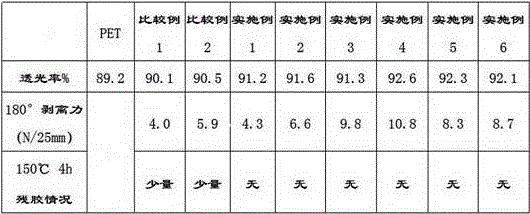

Image

Examples

Embodiment 1

[0039] A preparation method of pressure-sensitive adhesive, comprising the steps of:

[0040] 1) Weigh 3g of vinyl acetate, 54g of butyl acrylate, 1.2g of acrylic acid, 1.2g of hydroxyethyl acrylate, initiator AIBN: 0.18g (accounting for the total weight of vinyl acetate, butyl acrylate, acrylic acid, and hydroxyethyl acrylate) 0.3%), NVP: 0.6g, solvent: ethyl acetate 90g. Mix vinyl acetate, butyl acrylate, acrylic acid, hydroxyethyl acrylate, and NVP to obtain a monomer mixture. Take 20-50% of the above mixture and 30-60% of the total amount of ethyl acetate as the solvent, and pour it into a After heating to 80°C in a four-neck flask with a thermometer and a condenser tube, pour 35-55% of the total amount of the initiator AIBN into the reaction flask, start timing when reflux occurs in the condenser tube, and keep warm for 1 hour.

[0041] 2) After the reaction, 20-30% of the total amount of the remaining monomer mixture, solvent ethyl acetate, and initiator AIBN was evenly...

Embodiment 2

[0046] A preparation method of pressure-sensitive adhesive, comprising the steps of:

[0047] 1) Weigh 3 g of vinyl acetate, 53.1 g of butyl acrylate, 1.2 g of acrylic acid, 1.2 g of hydroxyethyl acrylate, initiator AIBN: 0.18 g, NVP: 1.5 g, solvent: 90 g of ethyl acetate. Mix vinyl acetate, butyl acrylate, acrylic acid, hydroxyethyl acrylate, and NVP to obtain a monomer mixture. Take 20-50% of the above mixture and 30-60% of the total amount of ethyl acetate as the solvent, and pour it into a After heating to 80°C in a four-neck flask with a thermometer and a condenser tube, pour 35-55% of the total amount of the initiator AIBN into the reaction flask, start timing when reflux occurs in the condenser tube, and keep warm for 1 hour.

[0048]2) After the reaction, 20-30% of the total amount of the remaining monomer mixture, solvent ethyl acetate, and initiator AIBN was evenly added dropwise into the reaction system within 1.5-2 hours using a constant liquid funnel, and then kep...

Embodiment 3

[0053] A preparation method of pressure-sensitive adhesive, comprising the steps of:

[0054] 1) Weigh 3g of vinyl acetate, 51.6g of butyl acrylate, 1.2g of acrylic acid, 1.2g of hydroxyethyl acrylate, initiator AIBN: 0.18g, NVP: 3g, solvent: 90g of ethyl acetate. Mix vinyl acetate, butyl acrylate, acrylic acid, hydroxyethyl acrylate, and NVP to obtain a monomer mixture. Take 20-50% of the above mixture and 30-60% of the total amount of ethyl acetate as the solvent, and pour it into a After heating to 80°C in a four-neck flask with a thermometer and a condenser tube, pour 35-55% of the total amount of the initiator AIBN into the reaction flask, start timing when reflux occurs in the condenser tube, and keep warm for 1 hour.

[0055] 2) After the reaction, 20-30% of the total amount of the remaining monomer mixture, solvent ethyl acetate, and initiator AIBN was evenly added dropwise into the reaction system within 1.5-2 hours using a constant liquid funnel, and then kept for 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com