Fermentation tank overflow collecting, separating and recycling device

A separation and recovery, fermenter technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical cleaning device, etc., can solve problems affecting output and quality, pollute the environment, etc. The effect of ensuring yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

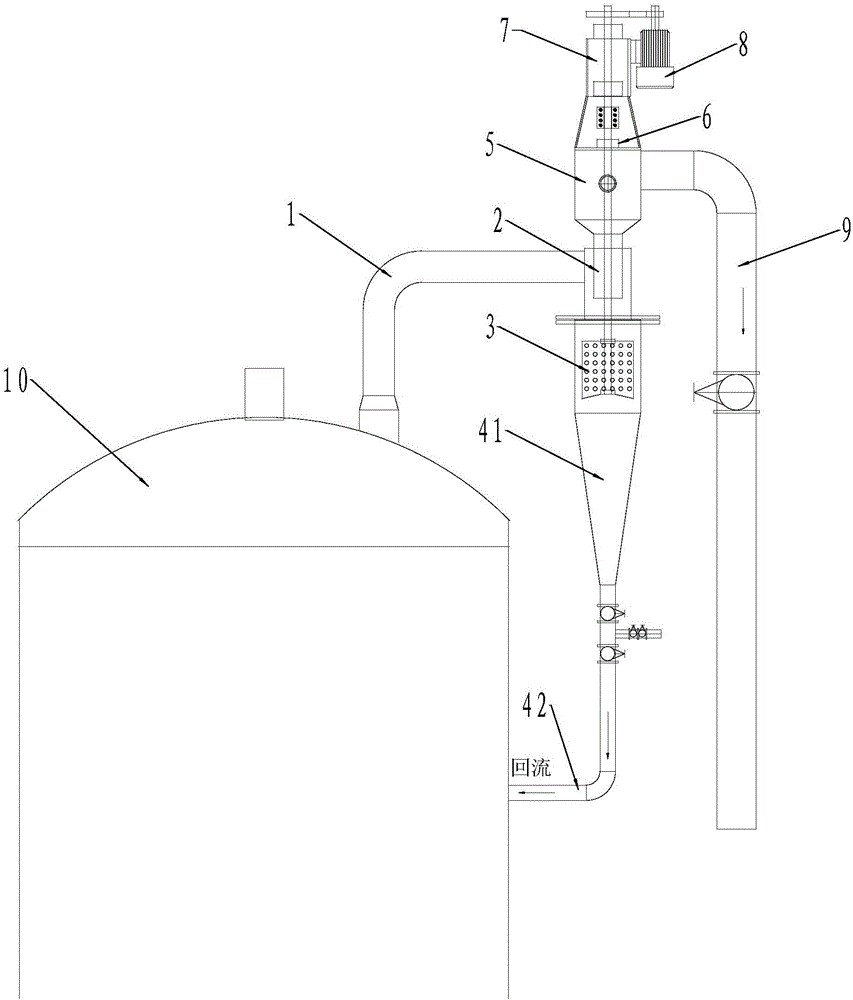

[0018] Such as figure 1 , Fermentation tank overflow collection, separation and recovery device, including a fermentation tank body 10, the exhaust pipe 1 on the tank body is equipped with a vapor-liquid cyclone separator 2 at the end, the separator 2 is connected with the liquid material collection pipe 41, and the liquid material collection pipe There is a centrifugal separator 3, and the end of the liquid material collection pipe is connected with a return pipe 42 and connected to the fermentation tank body. The cyclone separator 2 is provided with an exhaust observation pipe section 5, which is connected with the exhaust pipe 9 outside the tank. A speed reducer assembly 7 and a motor 8 are installed above the observation pipe section. The rotating shaft on the reducer assembly is connected to the centrifugal separator to drive the centrifugal separator to rotate, and the reducer assembly adjusts the motor speed. The end face mechanical seal 6 is used to seal between the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com