Thin gauge carriage body steel belt with yield strength of 600MPa, and manufacturing method of thin gauge carriage body steel belt

A yield strength and manufacturing method technology, which is applied in the field of thin-size box body steel strip with a yield strength of 600 MPa and its manufacturing field, can solve the problems of large production difficulties, tail flicking and poor plate shape, etc. Effects of formability and weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

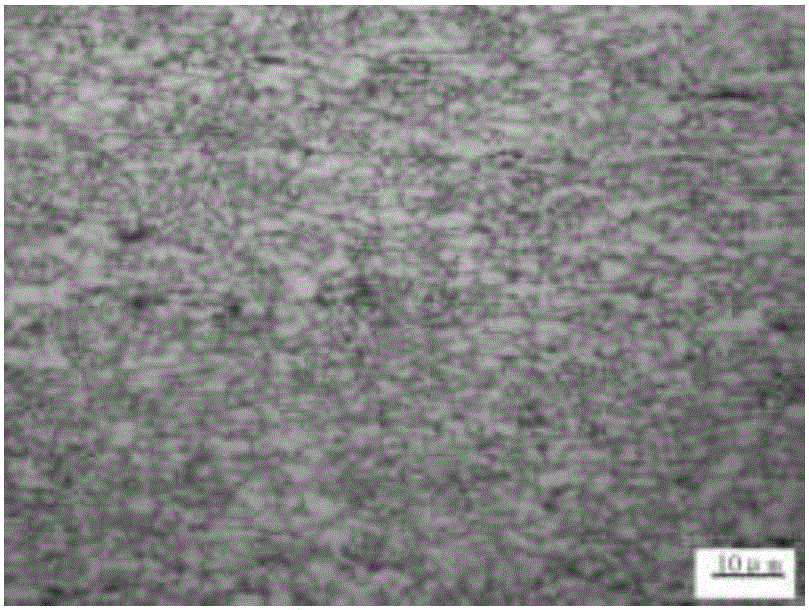

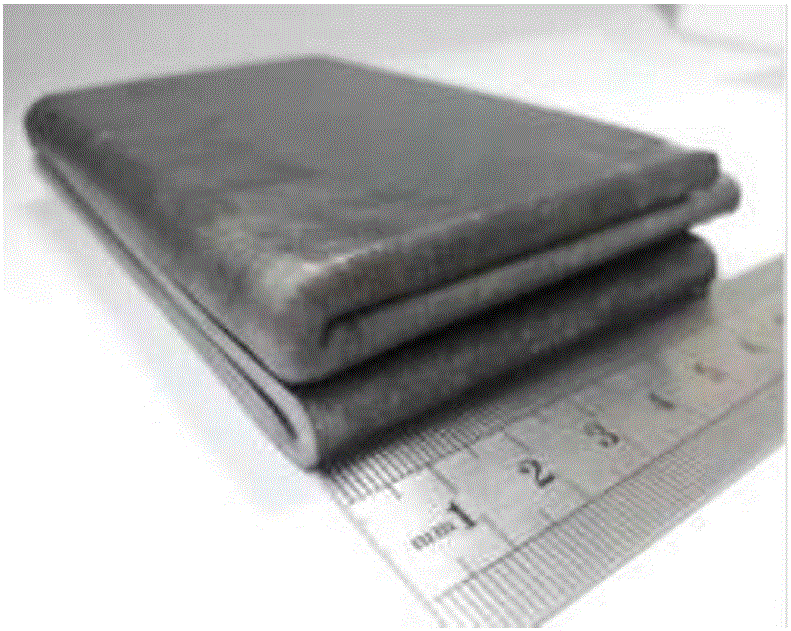

Image

Examples

Embodiment 1

[0038] The raw material molten iron is subjected to deep desulfurization of molten iron, converter top and bottom blowing, ladle blowing argon, LF refining outside the furnace and continuous casting process to obtain a 230mm thick slab with the chemical composition weight percentage shown in Table 1. The heating temperature of the slab is 1275°C, and the heating time is 185 minutes. The rough rolling is carried out in the R1 and R2 rough rolling mills, and the "3+3" passes are adopted. More than one pass is controlled at more than 20%; finish rolling is carried out in F1-F7 finish rolling mills, and the deformation of each pass is strictly controlled during finish rolling. Steel strip thickness 2.5mm. After rolling, the steel strip enters the laminar flow cooling system, and the average coiling temperature is 589° C., and finally the steel strip can be obtained.

Embodiment 2

[0040] The implementation is the same as in Example 1, wherein the heating temperature is 1271°C, the temperature is kept for 188 minutes, the finish rolling start temperature is 1003°C, the start rolling thickness is 39mm, the finish rolling temperature is 890°C, and the finished strip thickness is 2.75mm. After rolling, the steel strip enters the laminar flow cooling system, and the average coiling temperature is 588° C., and finally the steel strip can be obtained.

Embodiment 3

[0042] The implementation is the same as in Example 1, wherein the heating temperature is 1270°C, and the temperature is kept for 185 minutes; the finish rolling start temperature is 989°C, the start rolling thickness is 41mm, the finish rolling temperature is 884°C, and the finished steel strip thickness is 3.0mm. After rolling, the steel strip enters the laminar flow cooling system, and the average coiling temperature is 586°C, and finally the steel strip can be obtained.

[0043] Table 1 Chemical composition (wt %) of embodiment 1~3 of the present invention

[0044] Example C Si mn P S Nb Ti Alt 1 0.06 0.20 1.53 0.012 0.009 0.025 0.080 0.02 2 0.07 0.16 1.60 0.015 0.008 0.031 0.084 0.03 3 0.08 0.10 1.65 0.013 0.006 0.033 0.095 0.04

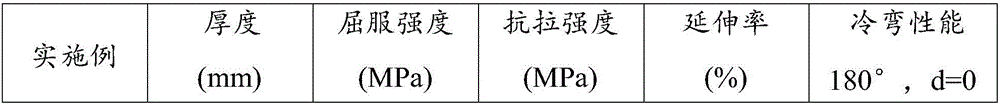

[0045] The steel plates of Examples 1-3 of the present invention were tested for their mechanical properties, and the test results are shown in Table 2.

[0046] The mechanical prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com