Offshore mooring chain steel and thermal treatment method for mooring chain

A heat treatment method and mooring chain technology, applied in the field of heat treatment of low-alloy steel and marine mooring chains, can solve problems such as uncontrolled maximum chain temperature, reduce the sensitivity of temper brittleness, strong intergranular bonding force, and uniform composition Effect

Pending Publication Date: 2017-05-10

殷匠

View PDF8 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

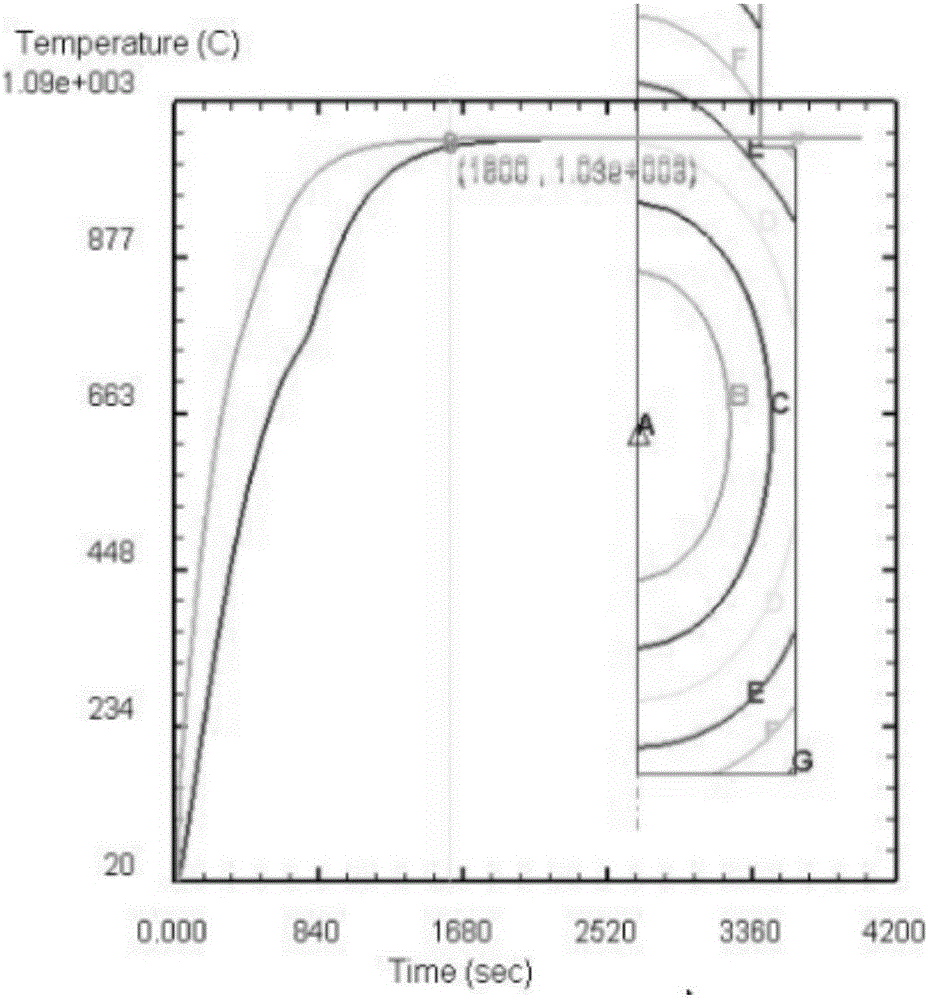

[0011] Chinese patent application number 200810033953.2 discloses that the quenching furnace temperature of the mooring chain is less than 1050°C, and there is no means of controlling the maximum chain temperature

In addition, the maximum height of the general inverted U-shaped vertical continuous furnace is only about 4m

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

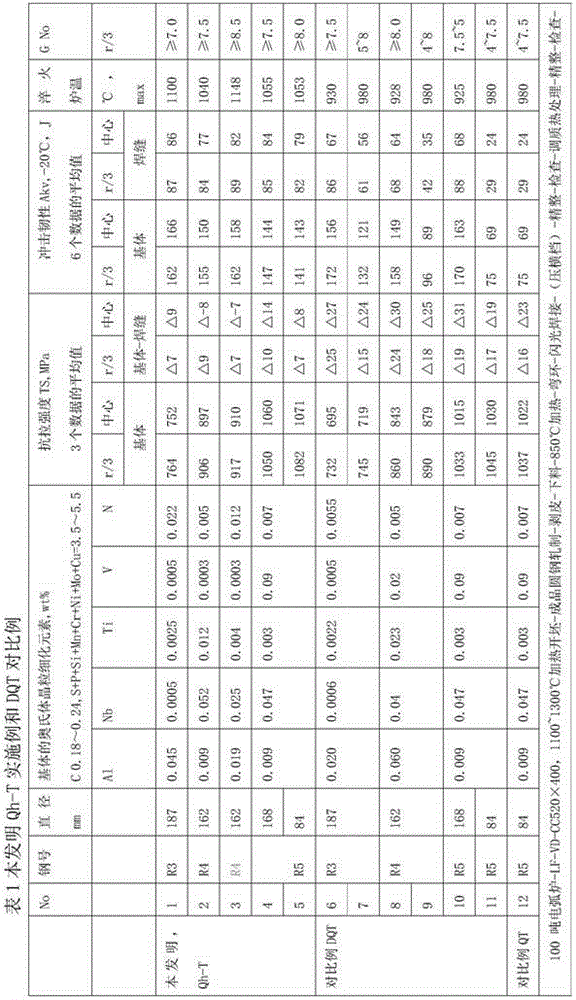

[0041] See Table 1 for details

[0042]

[0043]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses offshore mooring chain steel and a thermal treatment method for a mooring chain made of the offshore mooring chain steel. Austenitic grain refining elements in the offshore mooring chain steel comprise 0.006 to 0.024 percent of N by weight, and Al, Nb, Ti and V are precisely cooperated for use. The diameter of the offshore mooring chain is 70 to 210 mm, and a high-temperature quenching-tempering continuous thermal treatment process is adopted; and the furnace temperature of a quenching furnace is greater than 930 DEG C, the highest allowable furnace temperature is 1,150 DEG C, and tempering temperature is 590 to 690 DEG C. According to the offshore mooring chain steel, the potential of an alloy element is developed, the production period is substantially shortened, ideal tissue, substructure and performance can be obtained, and the equipment investment is reduced, so as to pursue the optimal cost performance.

Description

technical field [0001] The invention belongs to the field of heat treatment of low-alloy steel and marine mooring chains, and in particular relates to the composition design and manufacturing process of a class of fine-grained marine mooring chain steels, and in particular to a class of marine mooring chains and a heat treatment method thereof. Background technique [0002] Marine exploration, deep sea oil production, national defense construction, etc. all need mooring systems for positioning and mooring marine floating bodies. The main structure is the steel mooring chain. Mooring chains can be divided into three grades, three and a half grades, four grades, four and a half grades, five grades and six grades according to their strength levels. The tensile strength of chain links at all levels after quenching and tempering is not less than 690Mpa, 770Mpa, 860Mpa, 960Mpa, 1000Mpa and 1110Mpa respectively. The six-level chain is waiting for trial. The applicant has grouped...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/06C22C38/12C22C38/14C21D1/18

CPCC22C38/06C21D1/18C21D2211/001C22C38/001C22C38/12C22C38/14

Inventor 殷匠

Owner 殷匠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com