Method for preventing ozone bleached cotton fabric from yellowing

A cotton fabric and fabric technology, applied in the direction of plant fibers, textiles, papermaking, dry-cleaning fiber products, etc., can solve the problems of performance degradation, fabric brightness dimming, affecting fabric performance, etc., achieve stable performance indicators, high fabric stability, The effect of improving the properties of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

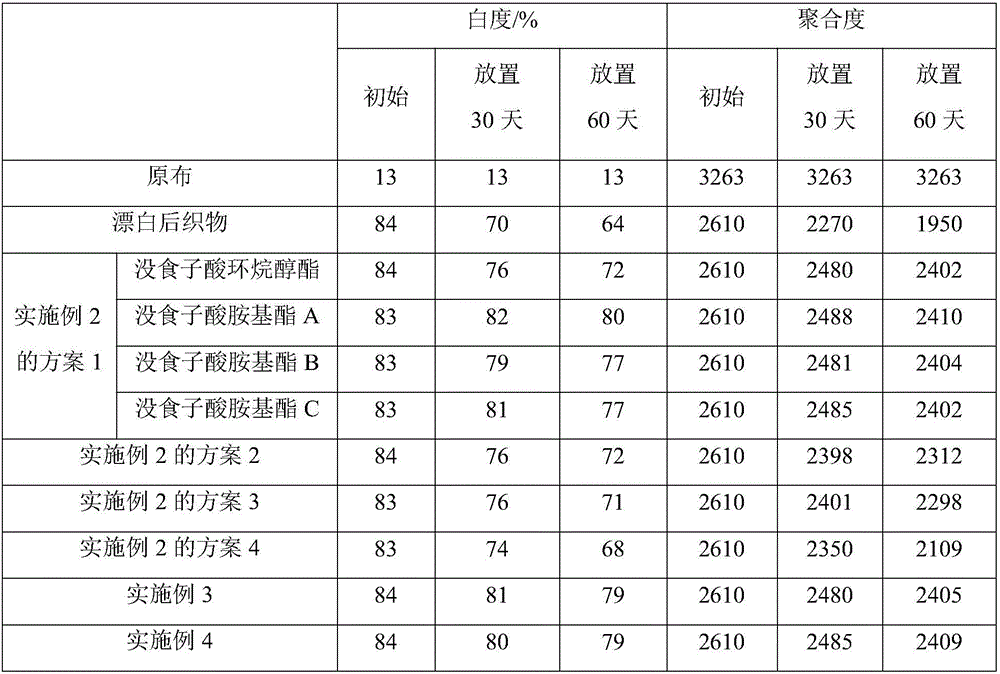

[0034] Example 1: Ozone Bleaching of Fabrics

[0035] The cotton fabric is soaked in ozone aqueous solution for a period of time to obtain ozone-bleached cotton fabric.

Embodiment 2

[0036] Example 2: Anti-Yellowing Treatment of Ozone Bleached Fabrics

[0037] The same ozone-bleached fabric was treated separately as follows:

[0038] plan 1:

[0039] (1) Immerse the ozone-treated cotton fabric into a 3% free radical scavenger solution and keep it immersed for 20 minutes.

[0040] (2) Place the washed cotton fabric in hot water at 50°C, keep it in contact for a certain period of time, and then place the fabric in a cold water bath to fully wash the fabric.

[0041] (3) Place the washed fabric above in an oven at 70° C. for a certain period of 3 hours.

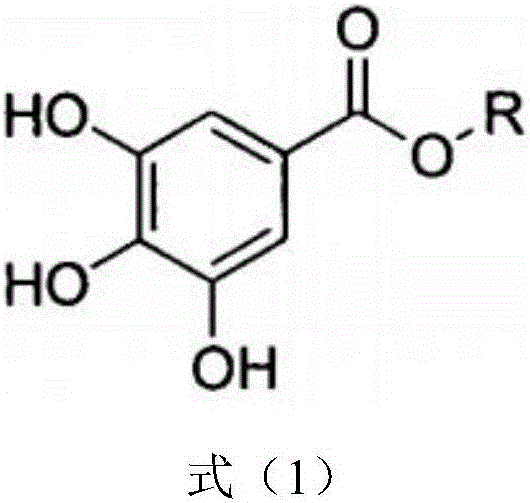

[0042] Wherein the free radical scavenger was tested respectively: cycloalkanol gallate, amino gallate A, amino gallate B, amino gallate C; wherein the amino gallate structural formula is as formula (1), The R groups of A, B, and C are respectively

[0043] Scenario 2:

[0044] (1) Immerse the ozone-treated cotton fabric in 3% sodium bisulfite solution and keep it immersed for 20 minutes.

[0045] (2...

Embodiment 3

[0055] The same ozone bleached fabric was treated as follows:

[0056] (1) Immerse the ozone-treated cotton fabric into the amino gallate A solution with a concentration of 1%, and keep soaking for 30 minutes;

[0057] (2) Put the washed cotton fabric in hot water at 60°C, keep it in contact for a certain period of time, and then place the fabric in a cold water bath to fully wash the fabric;

[0058] (3) Place the washed fabric above in an oven at 80° C. for a certain period of time to dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com