Method for removing cotton seed hulls on cotton fabrics in liquid phase by ozone

A cotton fabric, ozone technology, applied in the direction of plant fibers, textiles and papermaking, improved hand feel fibers, etc., to achieve the effects of good hand feeling, short process and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Cotton husk removal in cotton fabric

[0040] Cotton hulls were removed from desized fabrics by:

[0041](1) soaking the cotton fabric into the aqueous solution containing the non-ionic penetrant of 2g / L;

[0042] (2) Open the oxygen valve in advance to control the oxygen flow rate at 1.5L / min, then turn on the switch of the ozone reactor, and pass it into the immersion solution after the ozone is stable, keep the sealing of the reaction chamber (volume 2L), and continuously pass it into the water bath Ozone to obtain ozone water with an ozone concentration of 248 mg / L, and the fabric is immersed in this high-concentration ozone water bath for 20 minutes;

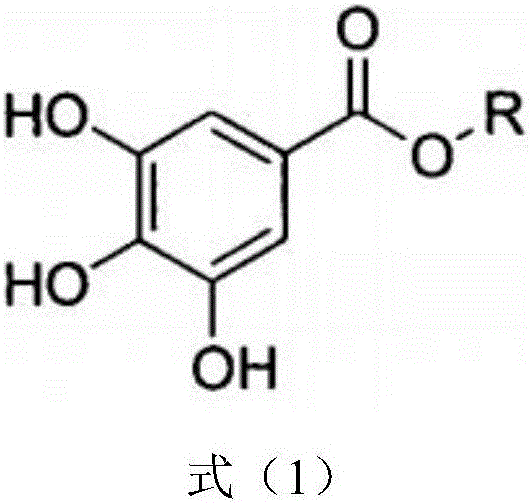

[0043] (3) After the reaction is completed, the cotton fabric is put into a 2% amino gallate A solution for rinsing reaction for 20 minutes, after rinsing is completed, continue to wash with hot water, wash with cold water, and finally dry. Wherein the structural formula of gallic acid amino ester is as ...

Embodiment 2

[0044] Example 2: Cotton husk removal in cotton fabrics

[0045] Cotton seed hulls were removed from desized cotton fabrics by the following methods:

[0046] (1) immerse the cotton fabric in the aqueous solution containing the non-ionic penetrant of 1g / L;

[0047] (2) Open the oxygen valve in advance to control the flow rate of oxygen at 1.5L / min, then open the switch of the ozone reactor, pass it into the soaking liquid after the ozone is stable, keep the sealing of the reaction chamber, and continuously pass into the water bath to obtain 248mg / min of ozone. L of ozone water, the fabric is immersed in this high-concentration ozone water bath for 20min;

[0048] (3) After the reaction is completed, the cotton fabric is rinsed in 1% amino gallate A solution for rinsing reaction for 30 minutes, after the rinsing is completed, continue to wash with hot water, wash with cold water, and finally dry.

Embodiment 3

[0049] Example 3: Cotton husk removal in cotton fabrics

[0050] Cotton seed hulls were removed from desized cotton fabrics by the following methods:

[0051] (1) immerse the cotton fabric in the aqueous solution containing the non-ionic penetrant of 1.5g / L;

[0052] (2) Open the oxygen valve in advance to control the flow rate of oxygen at 1.5L / min, then open the switch of the ozone reactor, pass it into the soaking liquid after the ozone is stable, keep the sealing of the reaction chamber, and continuously pass into the water bath to obtain 248mg / min of ozone. L of ozone water, the fabric is immersed in this high-concentration ozone water bath for 20 minutes, and the high-concentration ozone environment in the reaction chamber is maintained during this process;

[0053] (3) After the reaction is completed, the cotton fabric is put into a gallate solution with a concentration of 1% for rinsing for 30 minutes. After the rinsing is completed, continue to wash with hot water, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com