Method for performing gas bleaching on linen fabric by ozone

A technology of gas-phase bleaching and linen fabrics, which is applied to plant fibers, textiles, papermaking, and dry-cleaning fiber products. It can solve the problems of poor whiteness of bleached linen fabrics, easy yellowing of fabrics, high water consumption, etc., and meet the requirements of personal protection. Low, less human injury, less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

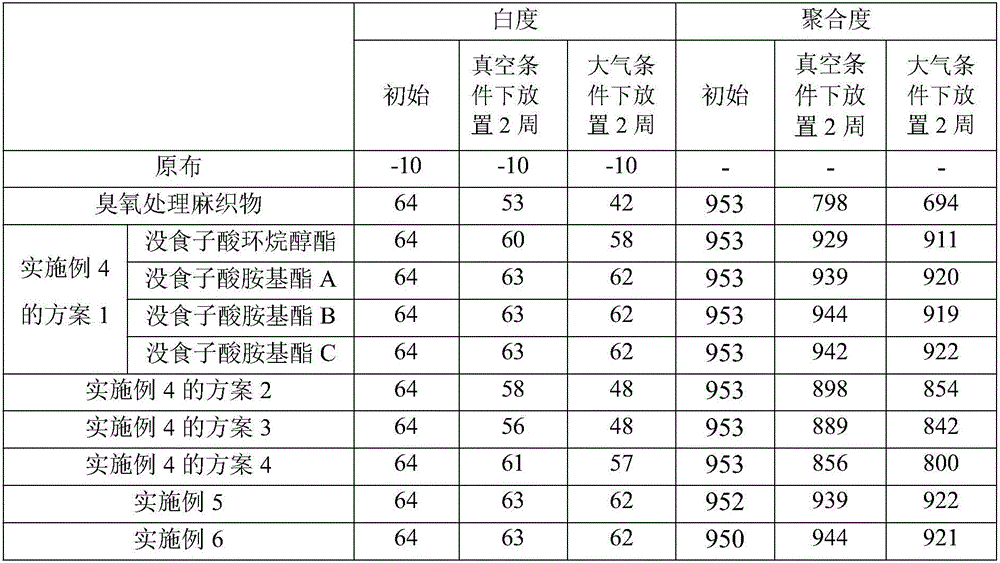

[0045] Embodiment 1: the ozone bleaching of hemp fabric

[0046] Linen fabric material: linen plain weave fabric.

[0047] Bleaching of linen fabrics is carried out as follows:

[0048] (1) Squeeze liquid process: place the hemp fabric after desizing and refining to soak in soft water, and process to make the liquid carrying rate of the fabric 30%;

[0049] (2) Bleaching process: Place a fabric with a certain liquid rate in the reactor, the ozone is input from one end, and the tail gas is output from the other end; the ozone concentration in the reactor is controlled to 240mg / L, the bleaching time is 20min, and the bleaching temperature is 10 ℃;

[0050] (3) Post-treatment process: After bleaching, take out the fabric, first wash it with hot water at 50-60°C, then wash it with cold water, and dry it.

[0051] The whiteness of the hemp fabric treated by this method has increased from -10 of the original fabric to 64; the whiteness decreased by 3 after being placed under vacu...

Embodiment 2

[0052] Embodiment 2: the ozone bleaching of hemp fabric

[0053] Linen fabric material: linen plain weave fabric.

[0054] Bleaching of linen fabrics is carried out as follows:

[0055] (1) Squeeze liquid process: place the hemp fabric after desizing and refining to soak in soft water, and process to make the liquid carrying rate of the fabric 20%;

[0056](2) Bleaching process: Place a fabric with a certain liquid rate in the reactor, the ozone is input from one end, and the tail gas is output from the other end; the ozone concentration in the reactor is controlled to 240mg / L, the bleaching time is 10min, and the bleaching temperature is 25 ℃;

[0057] (3) Post-treatment process: After bleaching, take out the fabric, first wash it with hot water at 60°C, then wash it with cold water, and dry it.

[0058] The whiteness of the hemp fabric treated according to this method has increased from -10 to 58 from the original cloth; the whiteness decreased by 5 after being placed und...

Embodiment 3

[0059] Embodiment 3: the ozone bleaching of hemp fabric

[0060] Linen fabric material: linen plain weave fabric.

[0061] Bleaching of linen fabrics is carried out as follows:

[0062] (1) Squeeze liquid process: place the hemp fabric after desizing and refining to soak in soft water, and process to make the liquid carrying rate of the fabric 40%;

[0063] (2) Bleaching process: Place a fabric with a certain liquid rate in the reactor, the ozone is input from one end, and the tail gas is output from the other end; the ozone concentration in the reactor is controlled to 240mg / L, the bleaching time is 15min, and the bleaching temperature is 35 ℃;

[0064] (3) Post-treatment process: After bleaching, take out the fabric, first wash it with hot water at 60°C, then wash it with cold water, and dry it. .

[0065] The whiteness of the hemp fabric treated by this method has increased from -10 to 59 of the original fabric; the whiteness has decreased by 4 after being placed under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com