Petroleum drilling machine achieving continuous motion of tripping in and tripping out and method for continuous motion of tripping in and tripping out

A technology of tripping and moving, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of affecting the stability of the wellbore wall, affecting the working efficiency of the drilling rig, and large bottom hole pressure fluctuations, and improving the stability of the wellbore. The effect of reducing the stop time of make-up and break-out and improving the speed of tripping and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

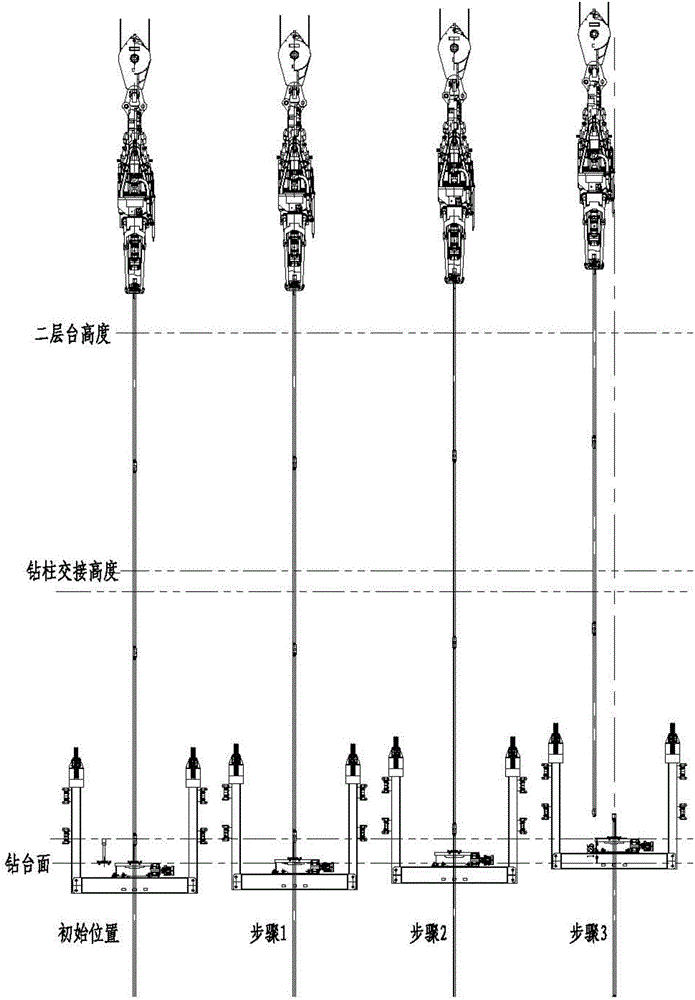

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

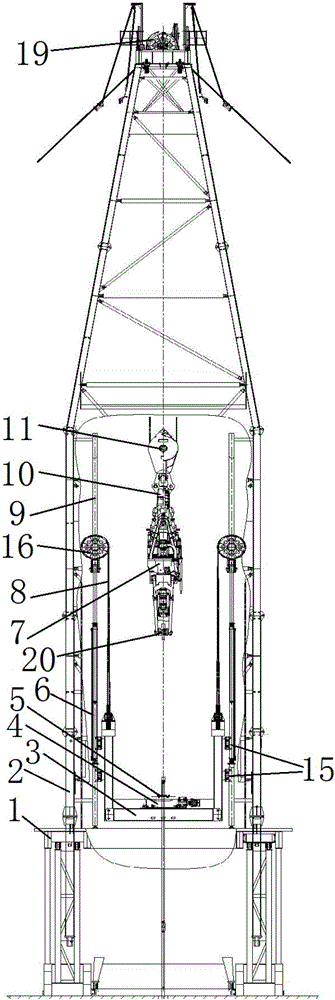

[0040] The continuous motion lifting diamond oil drilling rig (executive mechanism) of the present invention includes two sets of lifting mechanisms, one is the top drive lifting mechanism utilizing the existing top drive 7, and the other is the turntable lifting mechanism for driving the turntable 4;

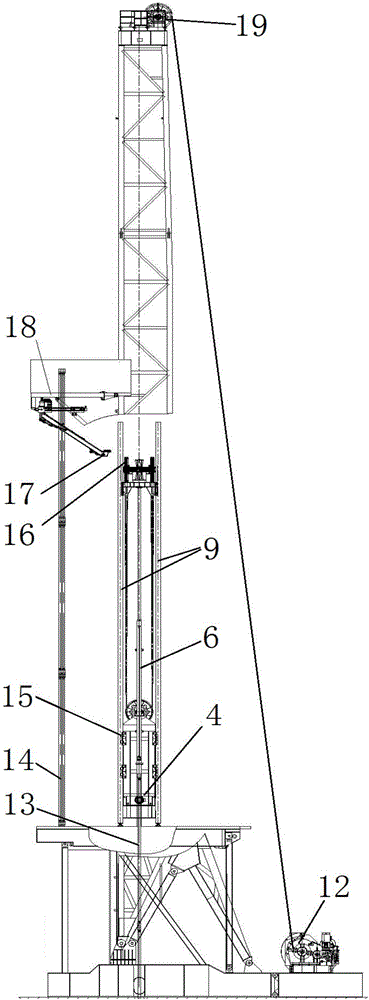

[0041] refer to figure 1 The top drive lifting mechanism of the present invention directly adopts the top drive lifting mechanism of the existing conventional oil drilling rig, including the crown block 19 at the top of the derrick 2, the traveling block 11 and the hook 10 at the middle of the derrick 2, the top drive 7, and the second floor platform 18 Derrick 17, winch 12 and its noose on the top;

[0042]Since the rotary table 4 and the rotary table beam 3 of the conventional oil drilling rig are installed on the drilling rig base 1, they ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com