Tunnel side wall reinforcement locator and locating method

A technology of tunnel side wall and positioning method, which is applied in tunnels, tunnel lining, earthwork drilling, etc., can solve the problems of poor tunnel structure durability, small thickness of steel protective layer, waste of steel bars, etc., so as to reduce the labor intensity of workers and the degree of mechanization. High, improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

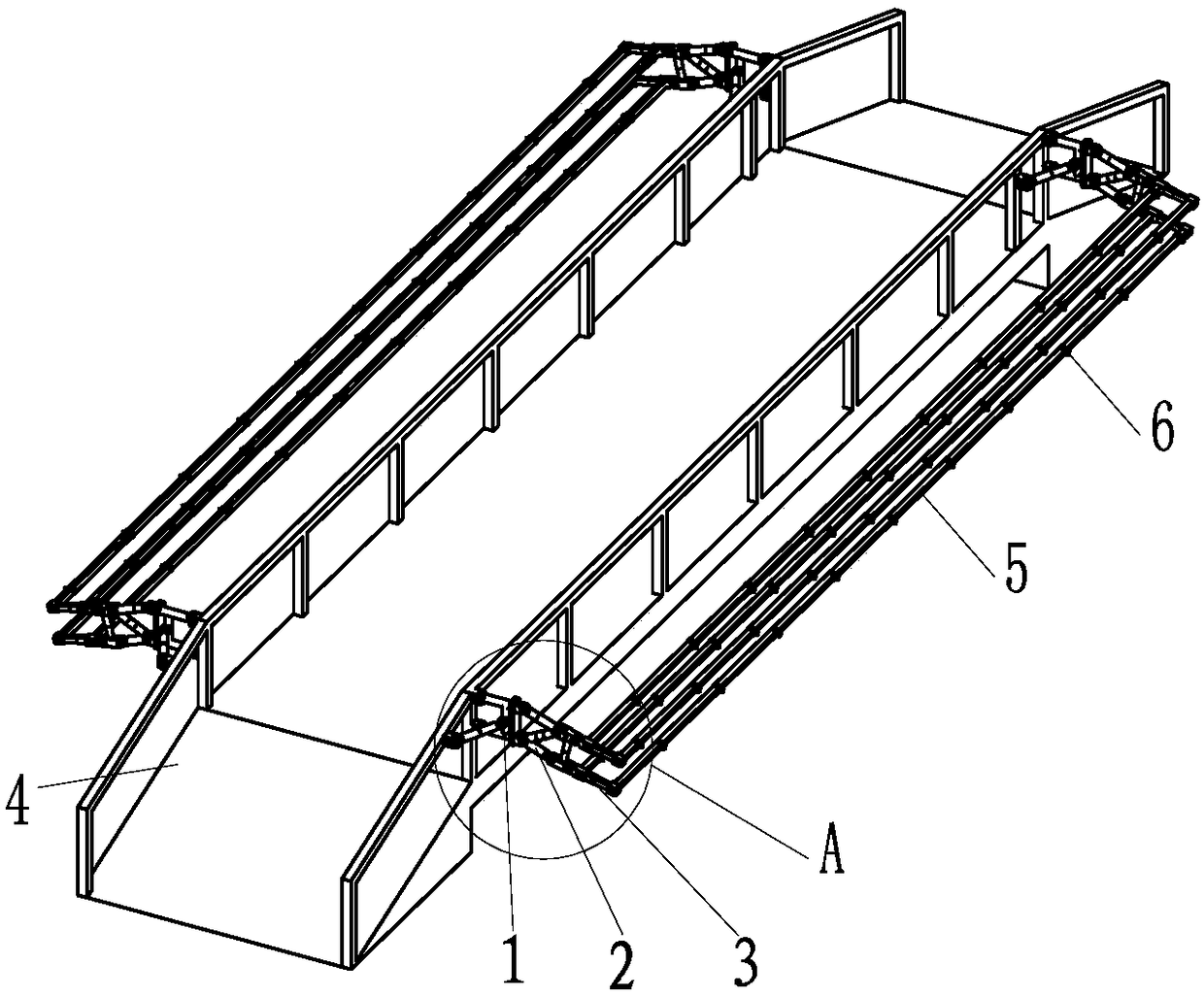

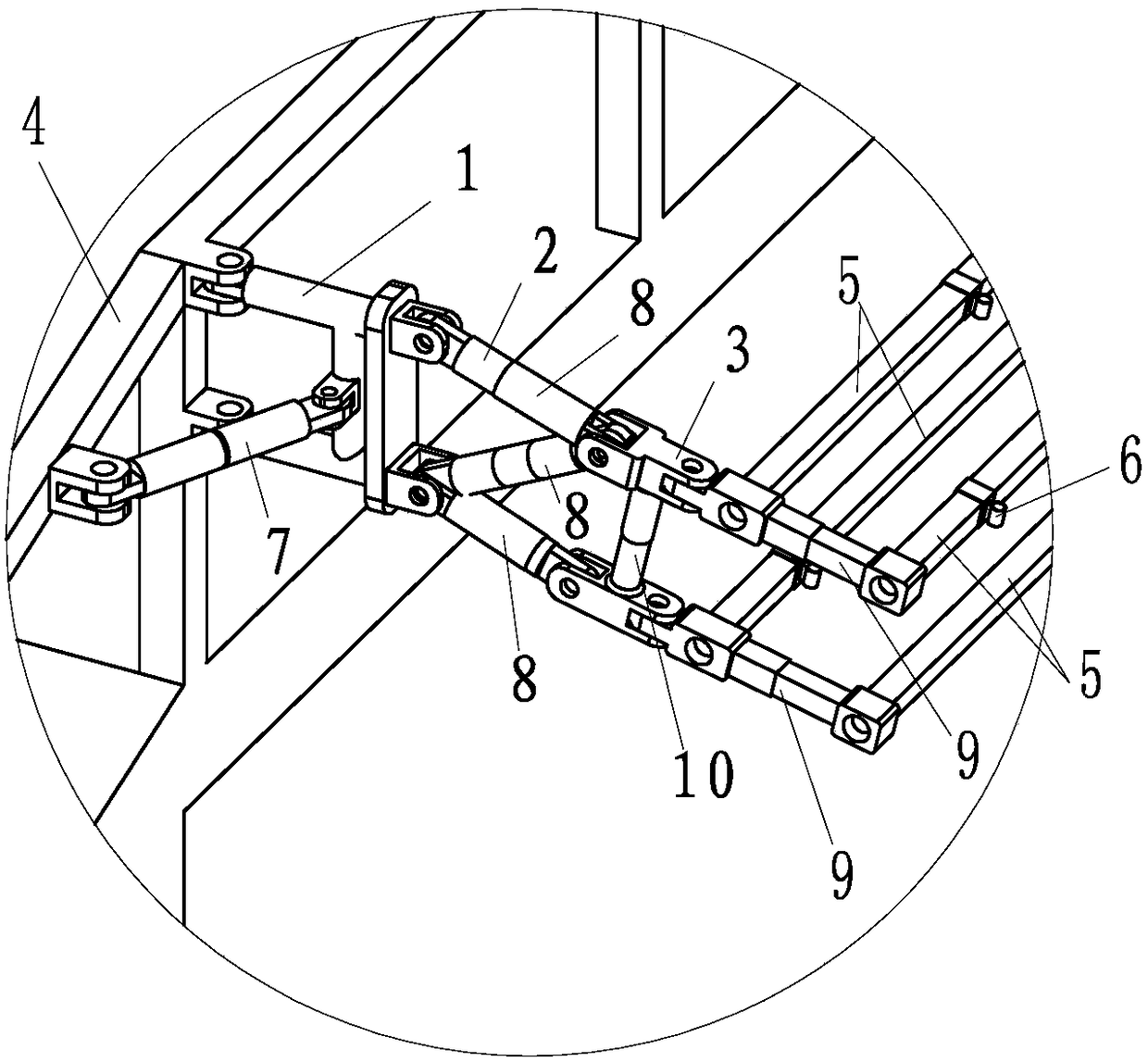

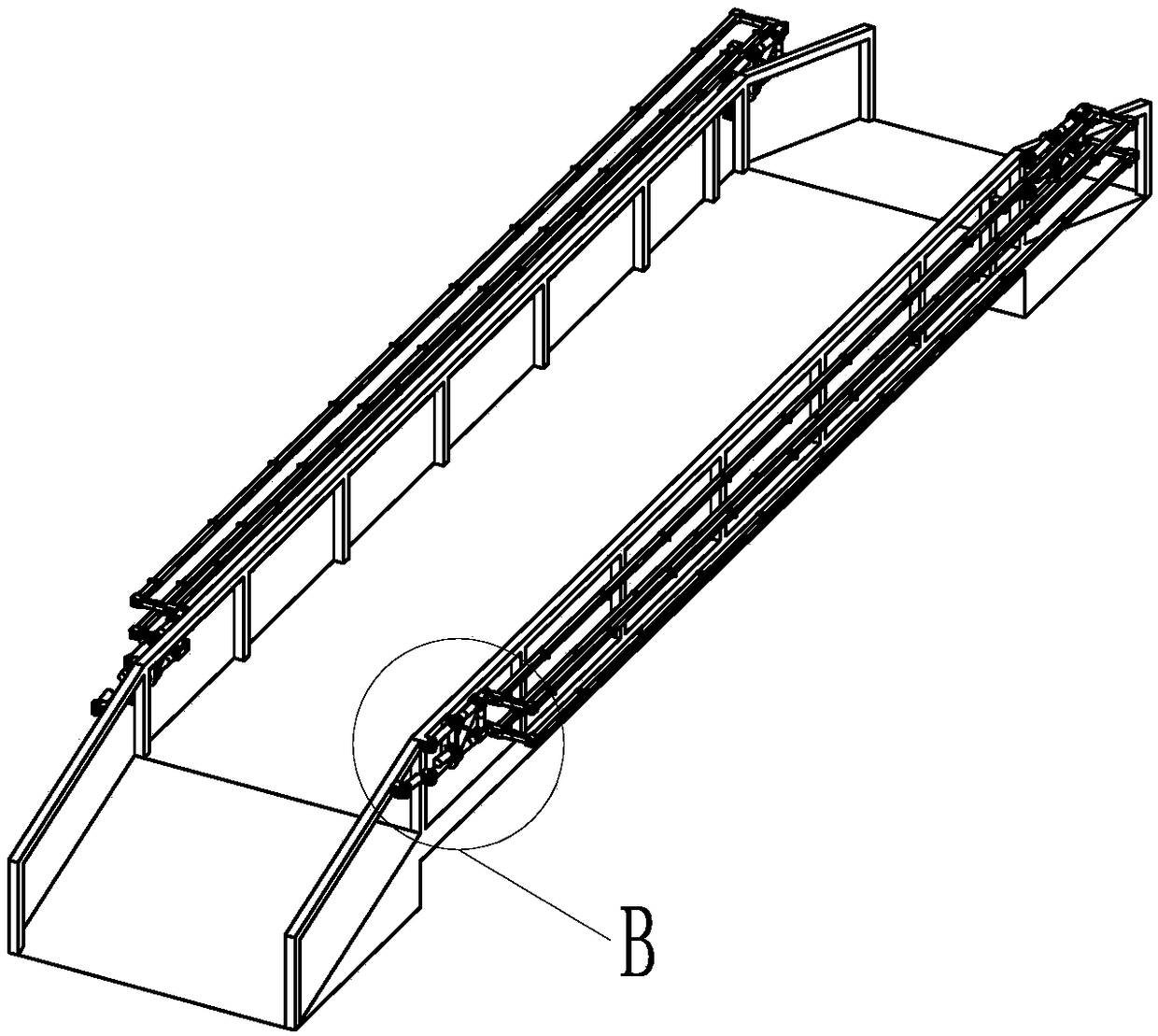

[0020] combine figure 1 — Figure 4 As shown, a steel bar positioner for a side wall of a tunnel is mainly composed of an inverted arch trestle 4, a steel bar positioning arm mechanism, a positioning rod 5 and a steel bar positioning clamp 6.

[0021] The inverted arch trestle 4 is divided into left and right sides, and two groups of reinforcing bar positioning arm mechanisms are respectively arranged on the left and right sides of the inverted arch trestle 4. On the same side of the inverted arch trestle 4, at least two groups of reinforcement positioning arm mechanisms should be set, but not limited to two groups.

[0022] Each set of reinforcing bar positioning arm mechanisms is composed of a large arm 1, a middle arm 2 and a small arm 3 which are sequentially hinged from inside to outside. The inner end of the boom 1 is hinged on the outside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com