A temperature and pressure reduction device

A technology for temperature reduction, pressure reduction, and pressure, which is applied in safety devices, steam engine devices, combined combustion mitigation, etc., can solve the problems of low energy cascade utilization efficiency and low thermal efficiency of units, so as to reduce the amount of steam used for three-extraction, improve thermal efficiency, The effect of improving unit economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

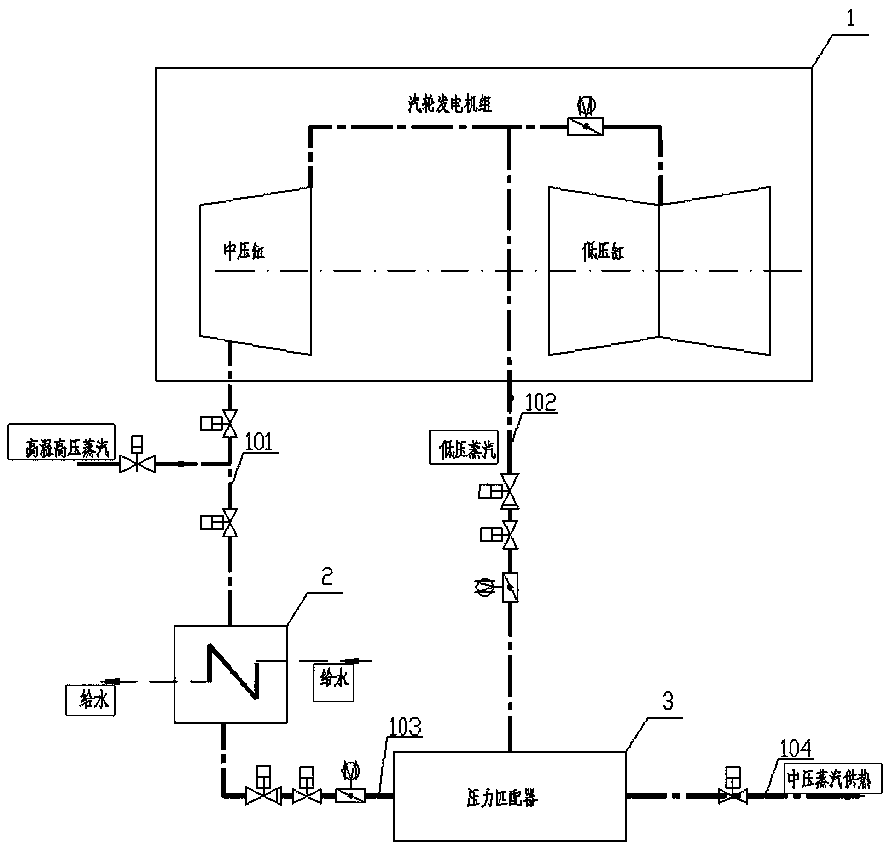

[0027] as attached figure 1 And attached figure 2 As shown, a kind of temperature and pressure reduction device of the present invention includes a condensing steam turbine 1, an external steam cooler 2, and a pressure matching device 3. The steam pipeline 101 is delivered to the external steam cooler, and the exhaust steam of the external steam cooler is delivered to the pressure matching device through the pipeline 103 and the connecting pipe of the medium and low pressure cylinder of the condensing steam turbine through the steam extraction pipeline 102, and the pressure The exhaust steam from the matcher is output through pipeline 104 for heat supply.

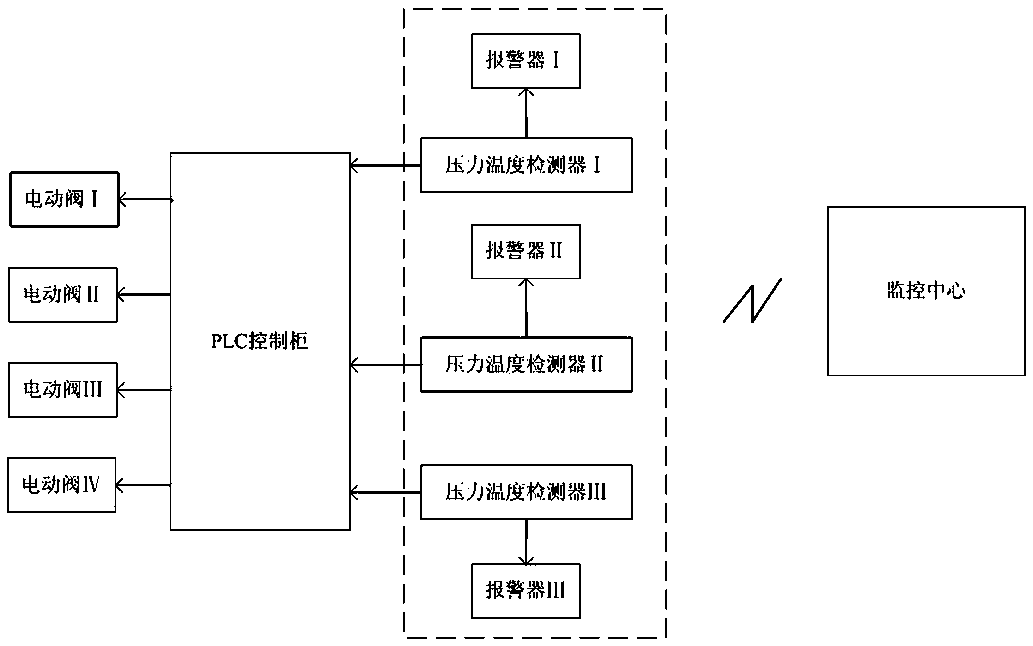

[0028] A temperature and pressure reduction device includes a PLC control cabinet, four electric valves, three pressure and temperature detectors, three alarms and a monitoring center; wherein, the inlet pipe of the return water heater 2 is provided with an electric valve Ⅰ, and pressure temperature detector Ⅰ, the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com