A chain type rotor hydraulic motor

A hydraulic motor and chain technology, applied in the field of chain-type rotor hydraulic motors, can solve the problems of reducing the mechanical efficiency of the hydraulic motor, reducing the volumetric efficiency of the hydraulic motor, and the arrangement of the plunger is not compact enough to achieve high torque, improve mechanical efficiency and reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

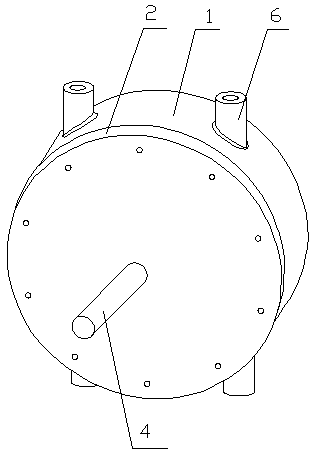

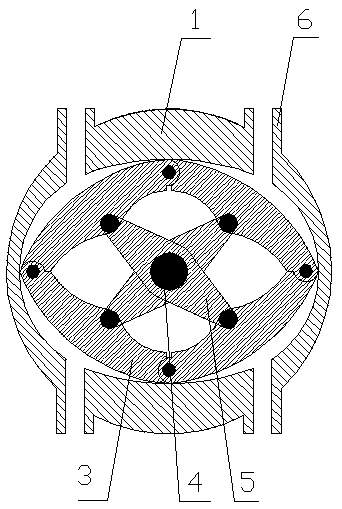

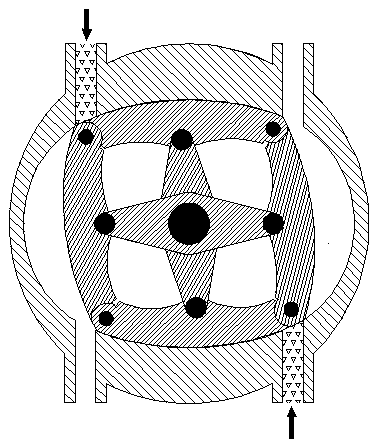

[0020] Such as figure 1 and figure 2 As shown, a chain-type rotor hydraulic motor of the present invention includes a cylinder body 1 and a chain-type rotor 5 arranged in the cylinder body 1, and the chain-type rotor 5 includes four arc-shaped chains 3 and a center shaft 4. The four chains 3 are hinged end to end to form a ring, and a hinged link 5 with a through hole in the center is provided between the two opposite chains 3, and the two ends of the hinged link 5 are respectively hinged on the opposite two chains. The middle part of the chain 3, the hinge connection of four chains 3 and two articulated connecting rods 5 jointly form the torque transmission mechanism of the present invention. The middle part of the central axis 4 is arranged in the through holes on the two hinged connecting rods 5 and is fixedly connected with one of the hinged connecting rods 5. In this embodiment, the central axis 4 and one of the hinged connecting rods 5 pass through The spline structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com