Programmable automatic control grouting pump for shield tunneling machine

A technology of shield machine and grouting pump, applied in machine/engine, pump, multi-cylinder pump, etc., can solve the problems of poor grouting pressure and continuity, high cost of control system, poor sealing performance of pump body, etc. performance, avoid mortar deposition, and reduce the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

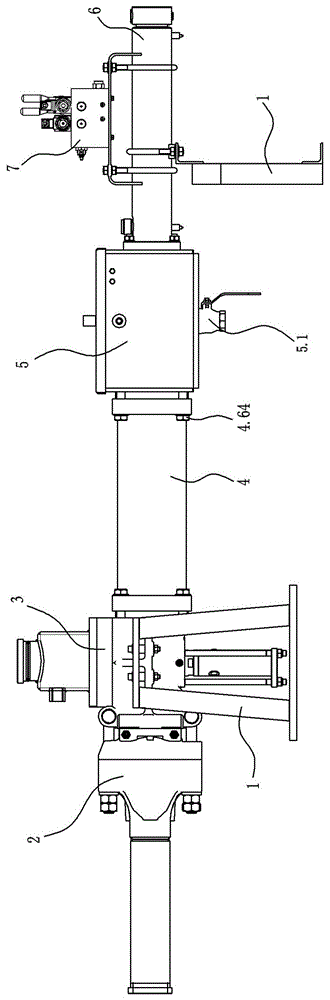

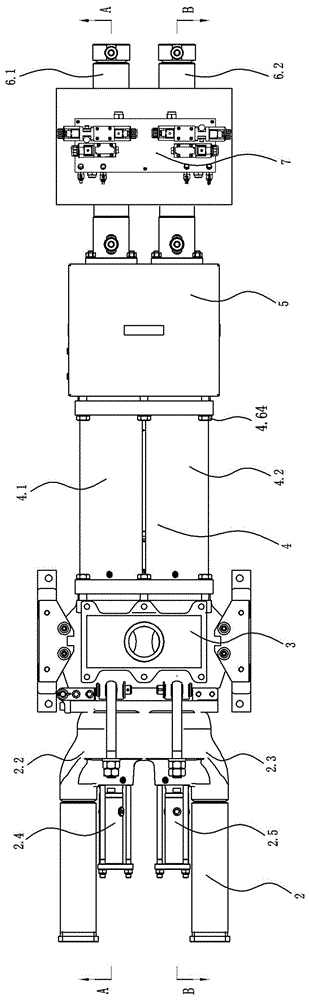

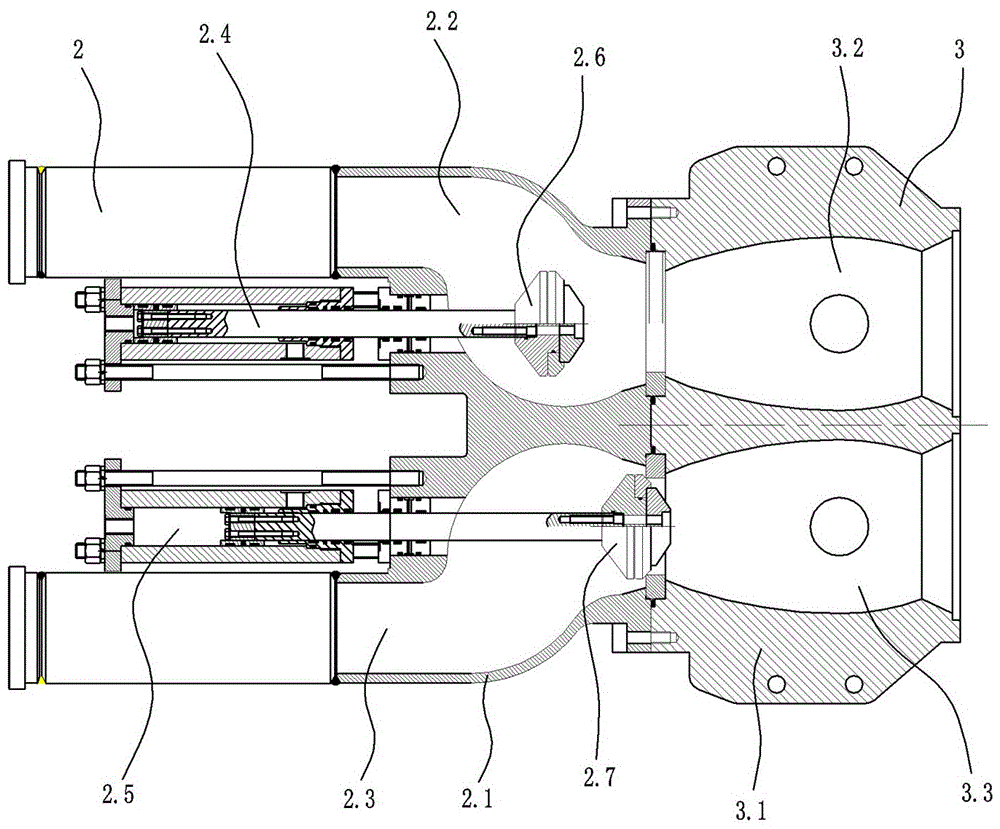

[0039] The programmable automatic control grouting pump for shield machine of the present invention is a programmable automatic control grouting pump for shield machine, comprising a support 1, which is fixedly installed on the shield machine, and also includes a discharge pump Mechanism 2, material suction mechanism 3, conveying cylinder mechanism 4, water tank 5, pumping oil cylinder 6 and hydraulic control valve group 7, the feeding end of the discharge mechanism 2 is fixed and communicated with one end of the material suction mechanism 3, and the material suction The other end of the mechanism 3 is fixed and communicated with one end of the delivery cylinder mechanism 4, the other end of the delivery cylinder mechanism 4 is fixed and communicated with the end of one side of the water tank 5, and the other end of the water tank 5 is fixedly installed with a pumping oil cylinder 6. The end of the piston rod of the oil delivery cylinder 6 passes through the interior of the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com