Integral type multi-way valve and working method thereof

An integral, multi-way valve technology, used in the field of multi-way valves, can solve the problems of increasing pipeline layout, throwing trash cans, and large energy loss, reducing pipeline layout, avoiding bucket throwing, and easy mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

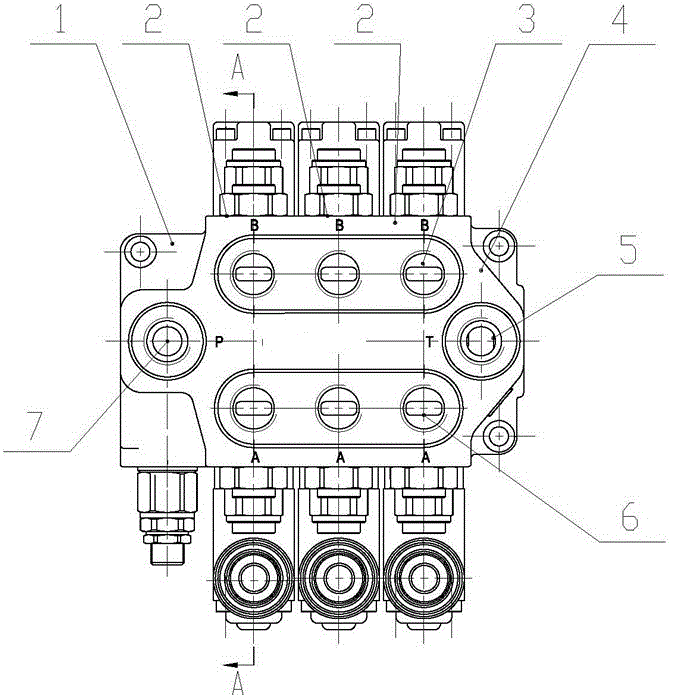

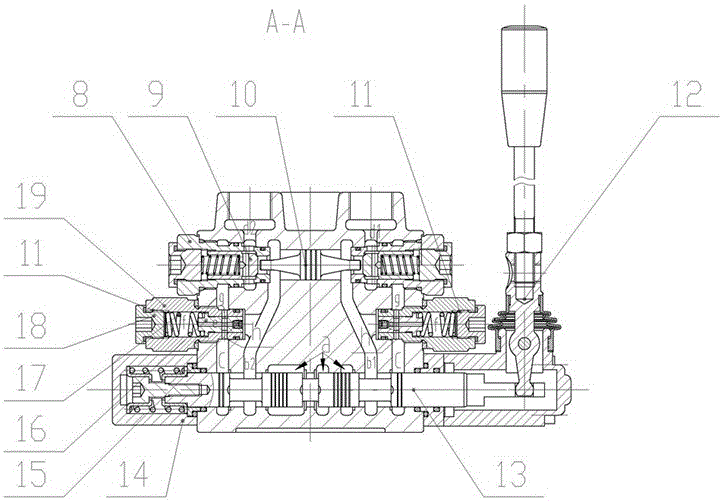

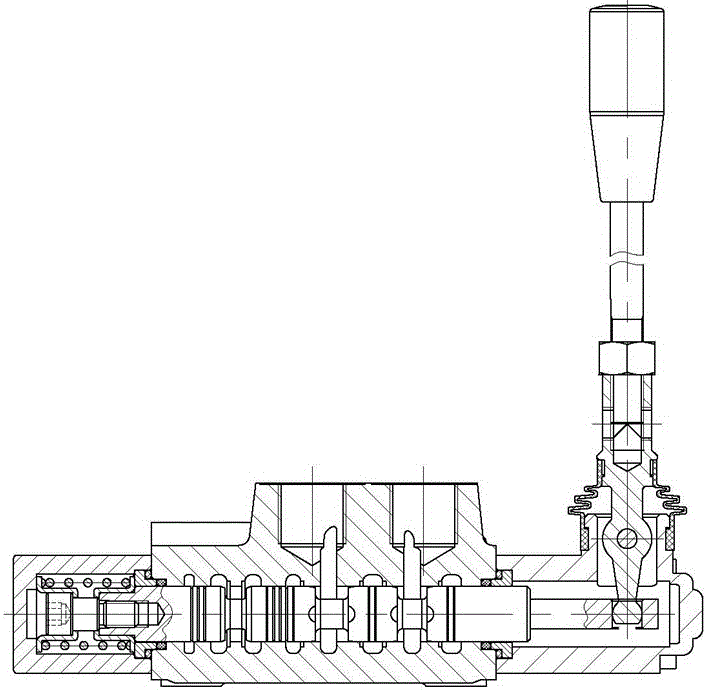

[0037] Such as figure 1 , 2 As shown, an integral multi-way valve includes an oil inlet valve unit 1, a plurality of working valve units 2 and an oil return valve unit 4; the plurality of working valve units 2 are arranged on the oil inlet valve unit 2 and Between the oil return valves 4; the oil inlet valve 1, the working valve 2 and the oil return valve 4 are integral structures; the oil inlet valve 2 is provided with an oil inlet P7, and the oil return valve The connection 4 is provided with an oil return port T5; each of the plurality of working valve connections 2 is provided with two working oil ports A6, B3; it is characterized in that: the working valve connection 2 is provided with a hydraulic lock 8, pressure compensation flow control The valve 11 and the reversing valve stem assembly 13 are arranged sequentially from top to bottom.

Embodiment 2

[0039] On the basis of Embodiment 1, a valve cavity is set in the working valve unit 2, and the hydraulic lock 8, the hydraulic lock control push rod 10, the pressure compensation flow control valve 11, and the reversing valve stem assembly 13 are all set in the valve cavity. Inside, the end cover 14 and the reversing operating mechanism 12 are placed outside the valve cavity through screw connection.

Embodiment 3

[0041] On the basis of Embodiment 1, the pressure-compensated flow control valve 11 is connected to the valve chamber through the thread on the valve sleeve 19, the throttle plug 15 is connected to the valve core 16 through the thread, and the valve core 16 is sleeved in the valve sleeve 19 , and withstand one end of the spring 17, and the other end of the spring 17 is provided with a plug 18.

[0042] Further, the valve core 16 is provided with an annular groove g, and the valve sleeve 19 is provided with a small hole h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com