A device and method for measuring the corrosion distribution characteristics of steel bar surface

A technique for distributing features, reinforcing bars, applied in measuring devices, employing optical devices, instruments, etc., to solve structural reliability performance (safety, serviceability and durability threats, structural bearing capacity and durability reduction, component bearing capacity and Deterioration of deformation performance and other problems, to achieve the effect of comprehensive automatic testing, improving accuracy and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

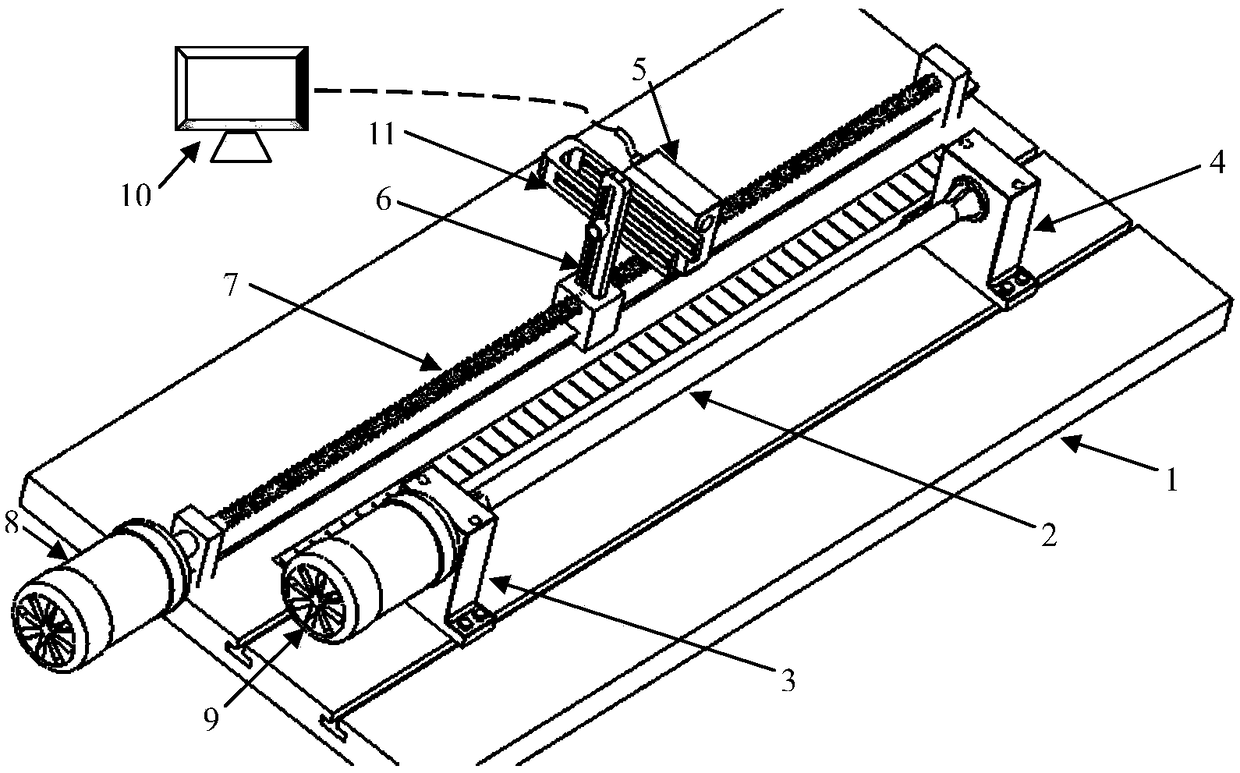

[0019] refer to figure 1 As shown, the device for measuring the corrosion distribution characteristics of steel bar surface of the present invention includes a base 1, a steel bar to be measured 2, and a laser distance measuring device 5. The steel base 1 has a slot that can be used for fixing and a scale that can be used for calibration. The laser sensing head of the distance measuring device 5 moves up and down, front and back, left and right on the base 1 through a moving device, the steel bar 2 to be measured is fixed on the base 1 by a clamping device, and the laser distance measuring device 5 is connected with a computer 10 . The laser distance measuring device has the advantages of high precision, large data collection and storage capacity. The laser sensor head emits laser light towards the surface of the steel bar to be tested and receives the reflected sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com