Automatic measurement system for external contour dimensions of motor vehicle and measurement method

A technology for automatic measurement of external dimensions, applied to measuring devices, instruments, optical devices, etc., can solve problems such as interference measurement, time-consuming and laborious, etc., and achieve the effects of safe and convenient use, fair guarantee, and novel system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

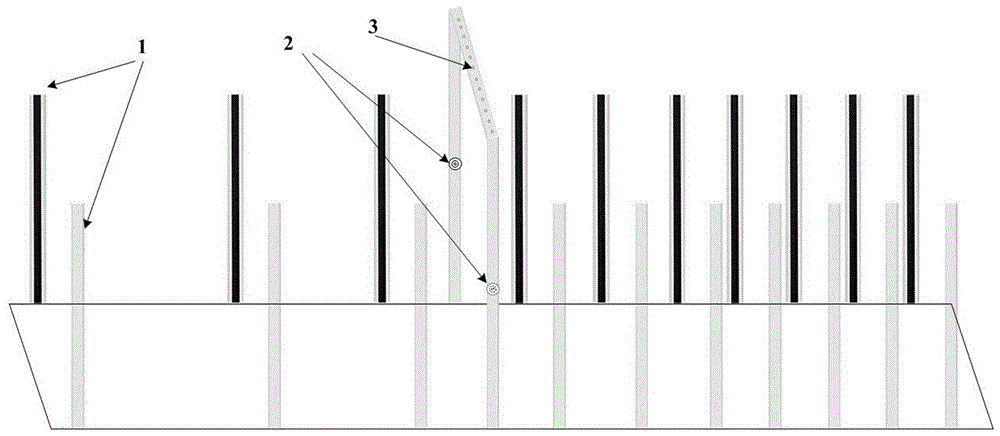

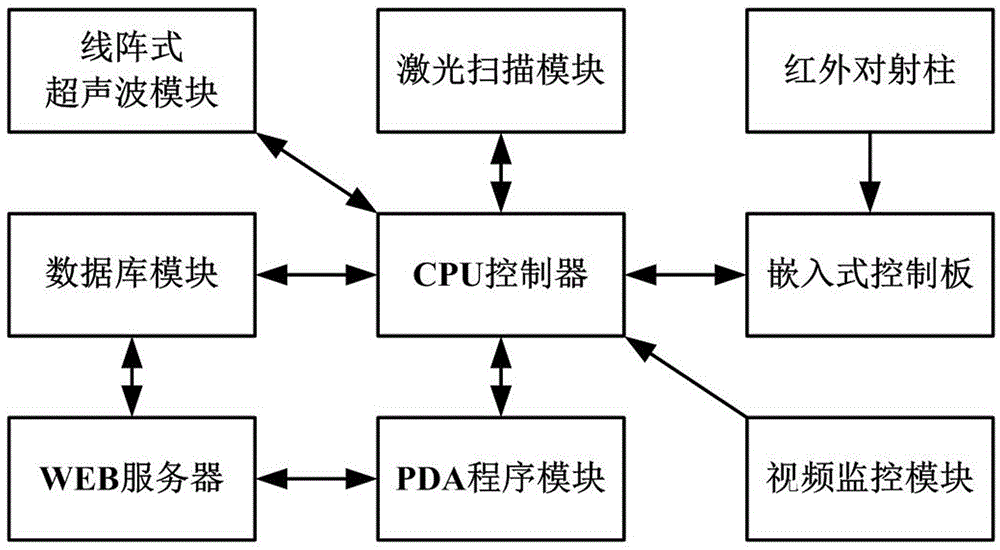

[0038] Such as figure 1 As shown in the figure, an automatic measurement system for the outer dimensions of a motor vehicle consists of multiple sets of infrared facing curtain walls as the length measurement mechanism, one set of linear array ultrasonic detection devices as the height measurement device, and two sets of laser distance measuring devices as the width measurement device. Embedded microprocessor composition.

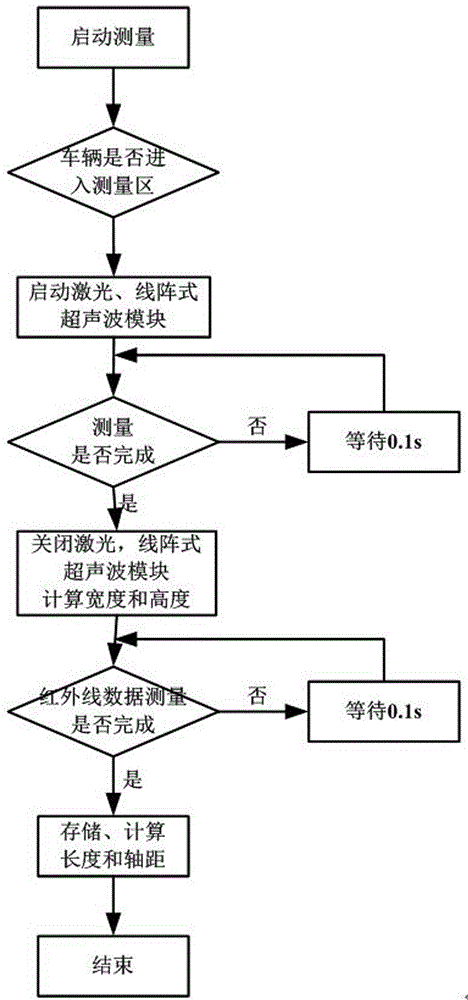

[0039] The multiple groups of infrared facing curtain walls are arranged in a non-equidistant manner and connected to the embedded microcontroller. When the vehicle passes through the measurement area at a speed of 10Km, the vehicle will block and not block (release) the infrared facing groups in turn, embedded The micro-controller collects real-time infrared signals, records the infrared group number and time blocked by the front end of the vehicle, records the infrared group number and time when the vehicle leaves, and the embedded microcontroller will co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com