A thin film differential pressure core

A differential pressure, thin film technology, applied in the measurement of fluid pressure, fluid pressure measurement through mechanical components, elastic deformation meter type fluid pressure measurement, etc., can solve resistance drift, can not directly measure water vapor, water or other corrosive liquids Pressure, measurement error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

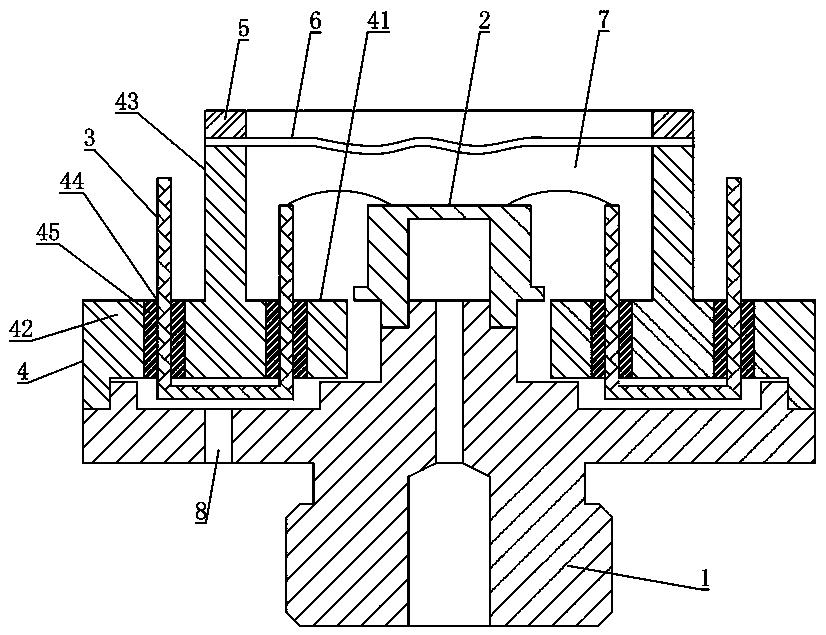

[0021] Such as figure 1 As shown, the film differential pressure core of this embodiment includes a tube base 1, a chip 2, a lead post 3 and a lead bracket 4, the chip 2 is installed in the middle of the tube base 1, and the lead bracket 4 includes an inner ring 41 and an outer ring 42 And the ring 43, the outer peripheral side of the outer ring 42 is sealed with the socket 1, the ring 43 is located between the inner ring 41 and the outer ring 42 and protrudes from the front surface of the chip 2, and the end of the ring 43 is equipped with a pressure ring 5 A corrugated diaphragm 6 is sealed between the end of the ring 43 and the pressure ring 5, wherein the pressure ring 5 cooperates with the end of the ring 43 to seal and install the corrugated diaphragm 6; the corrugated diaphragm 6, the tube seat 1 and the lead bracket 4 enclosing and for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com