Method for measuring aging depth rang of composite insulator umbrella skirt material

A composite insulator, depth range technology, applied in the direction of weighing by removing certain components, can solve the problems of inability to evaluate the aging depth range of composite insulator shed materials, and the inability to accurately and objectively reflect the aging of insulator sheds, etc. Achieve the effect of quickly judging the aging trend and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

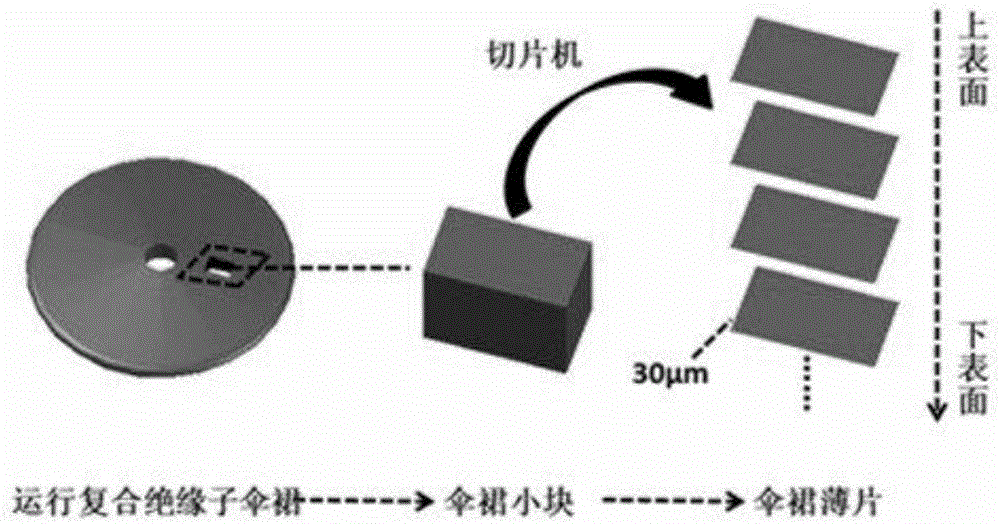

[0032] Take line A to run the composite insulator shed, whose main component content is unknown, and measure the aging depth range of the composite insulator shed material, including the following steps:

[0033] (1) Cut a piece of sample from the shed of the running composite insulator on line A, clean the dirty surface with absolute ethanol and dry it in a drying oven for 12 hours before use.

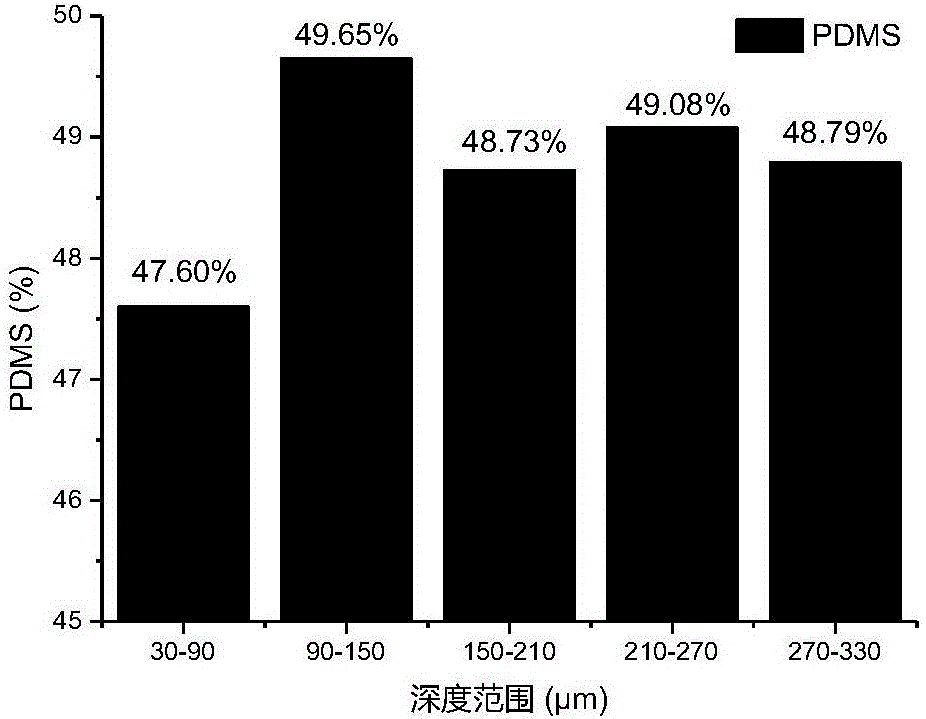

[0034] (2) Use the YD-2508A rotary microtome to slice the samples from the upper surface and sort and number them sequentially. In order to eliminate the influence of contamination on the experiment, remove the first slice, and then make two sets of slices to obtain 5 sets of slices in turn. sample.

[0035] (3) Place 5 groups of sliced samples in an electric drying oven, dry them at 30°C for 12 hours, cool to room temperature and transfer them to a drying cabinet; take out the samples one by one, cut them into tiny pieces and Put it into the German Netzsch STA449 comprehensive the...

Embodiment 2

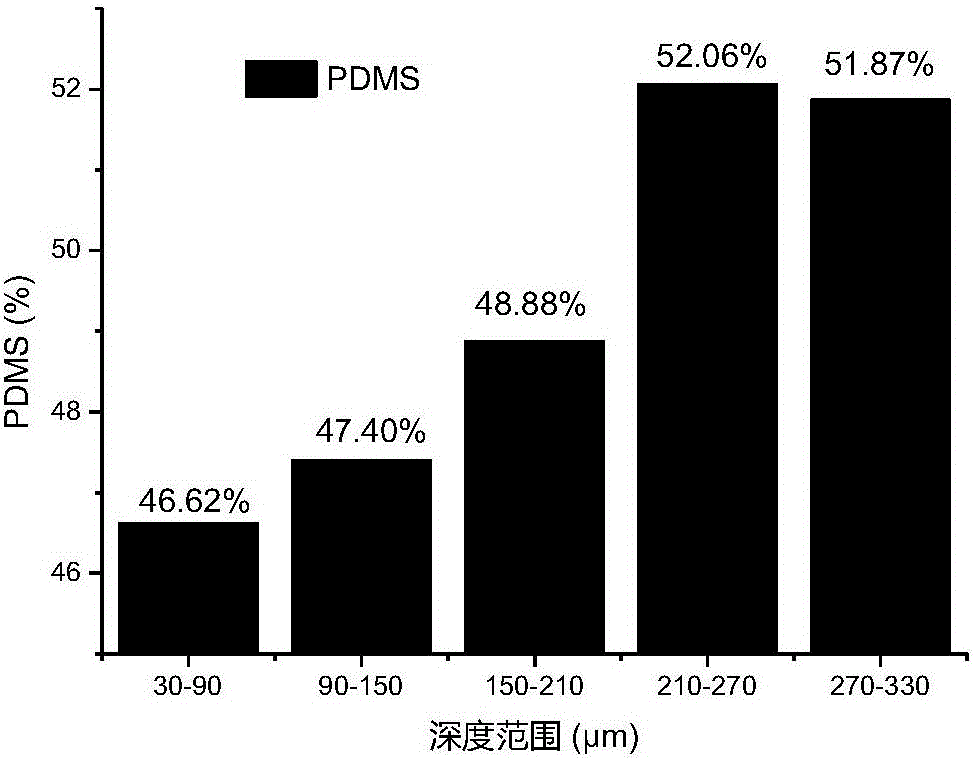

[0044] The shed of the composite insulator with broken strings running on line B is taken. The shed has obvious signs of ablation near the broken part, and the aging is relatively serious; the content of its main components is unknown. The aging depth range of the silicone rubber material in the shed is measured, including the following step:

[0045] (1) Cut a piece of sample from the composite insulator shed of broken strings running on line B, clean the dirty surface with absolute ethanol, and dry it in a drying oven for 12 hours before use.

[0046] (2) Use the YD-2508A rotary microtome to slice the samples from the upper surface and sort and number them sequentially. In order to eliminate the influence of contamination on the experiment, remove the first slice, and then make two sets of slices to obtain 5 sets of slices in turn. sample.

[0047] (3) Place 5 groups of sliced samples in an electric drying oven, dry them at 30°C for 12 hours, cool to room temperature and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com