Elevator sliding guide shoe liner testing machine

A sliding guide shoe and testing machine technology, which is applied in the direction of electromagnetic wave re-radiation, radio wave measurement system, measurement device, etc., can solve the problems of fewer stations and inability to detect wear on-line, and achieve the effect of protecting equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

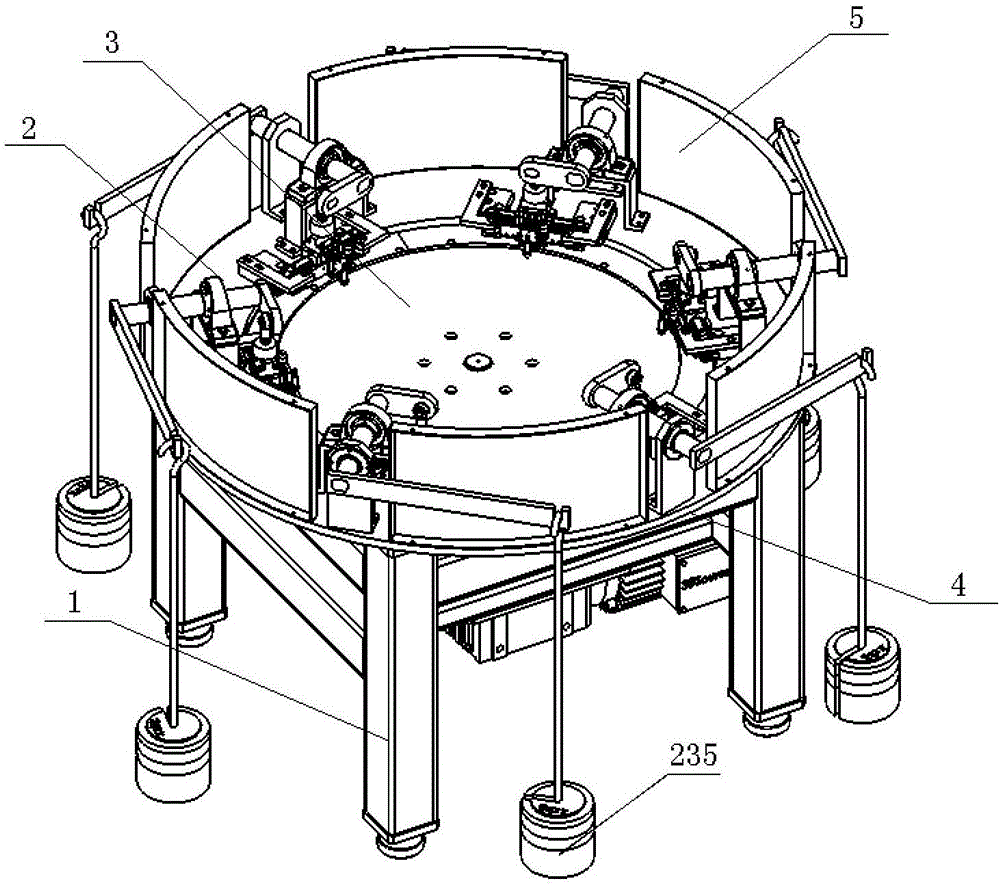

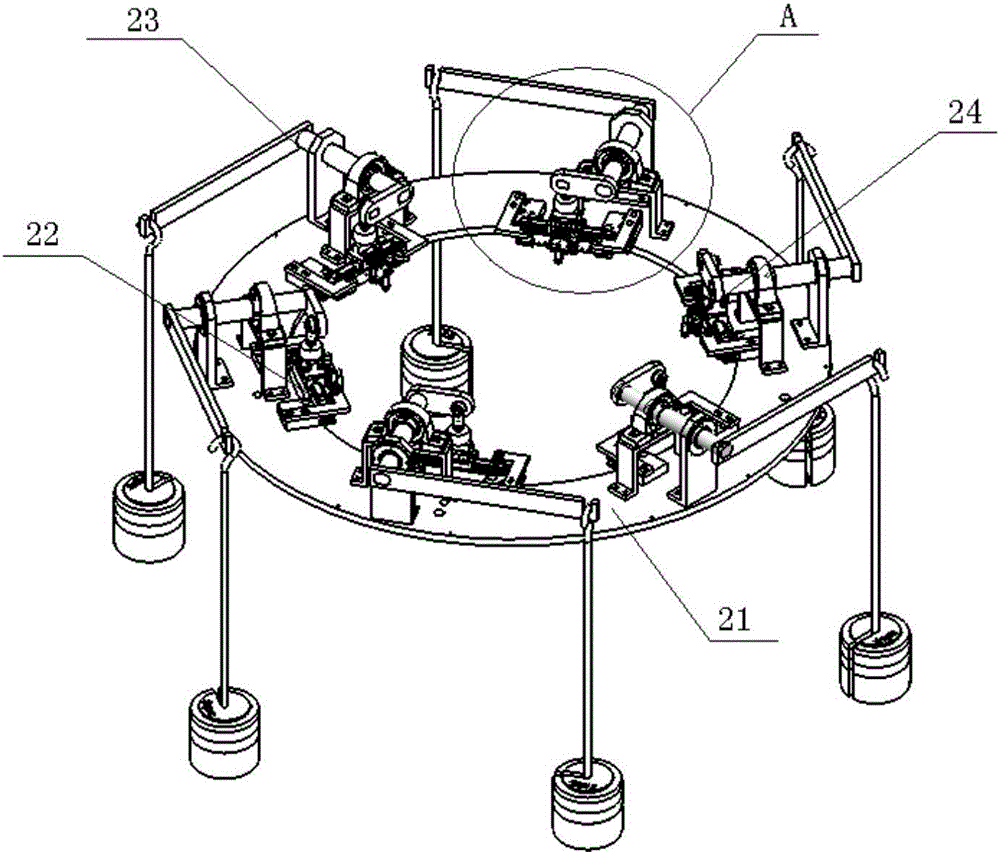

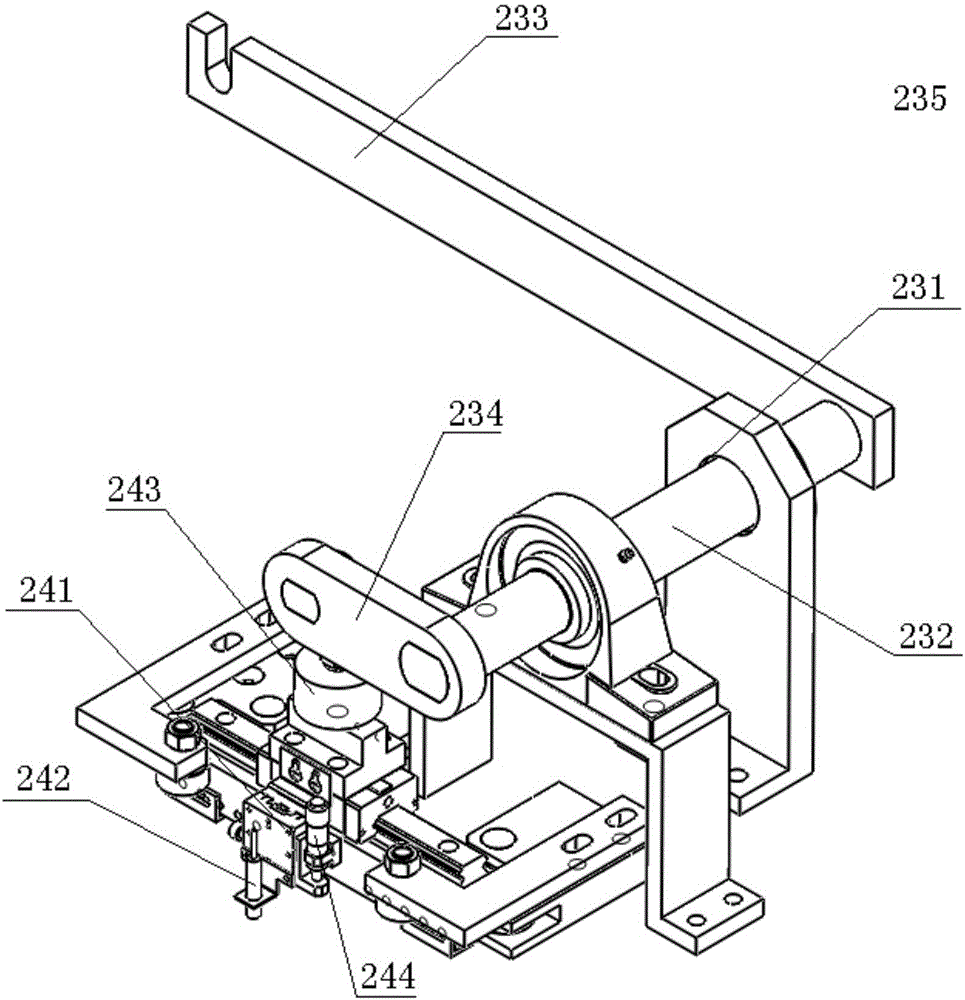

[0031] The present invention provides a testing machine for elevator sliding guide shoe linings, comprising: a work assembly system 1, a drive system 2 and a control system, the work assembly system 1 includes a work surface 21 and at least one A jig 22 for clamping the test shoe lining, at least one loading device 23 that gives the sample simulated pressure, and at least one wear measuring device 24 that can detect the amount of wear in real time online. The drive system 2 includes a drive motor 31 that will drive the motor The transmission shaft 32 of the kinetic energy output of 31 and the turntable 33 connected on the transmission shaft 32, the turntable 33 is fixedly installed with at least one detachable and detachable friction plate 34 in the shape of a simulated guide rail, and the control system is respectively connected to the loading device 23 , wear measuring device 24 and drive motor 31.

[0032] The working assembly system 1 includes multiple sets of test units c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com