SLD (superluminescent diode) light source test system

A test system and light source technology, applied in the direction of diode test, single semiconductor device test, etc., can solve the problems that cannot be directly used to measure system performance, cannot fully and accurately reflect the quality of SLD light source, and achieve direct and effective technical reference indicators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

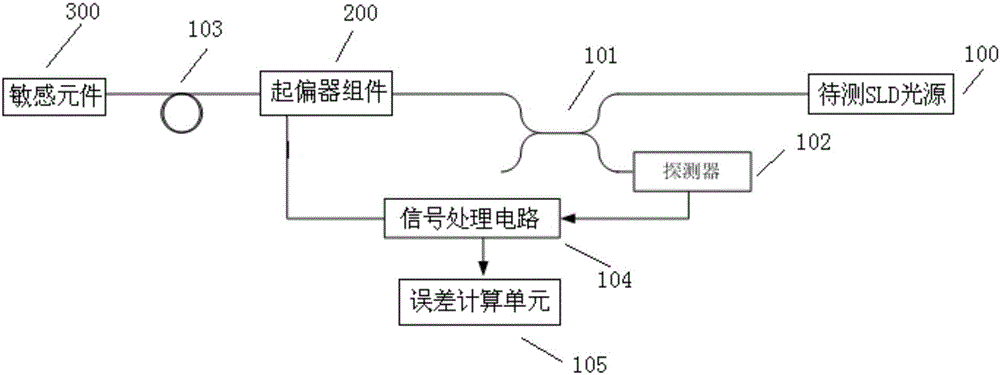

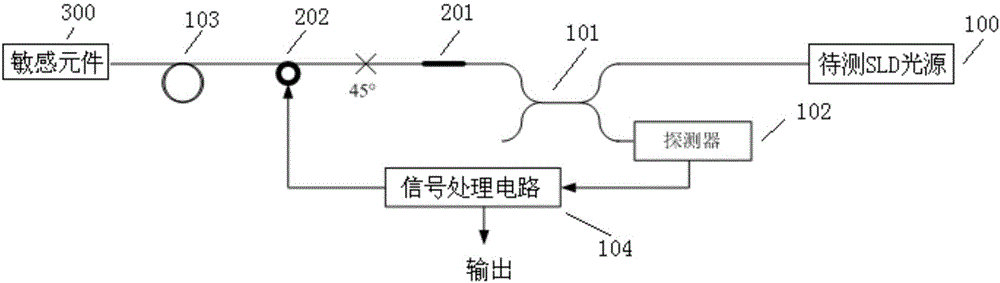

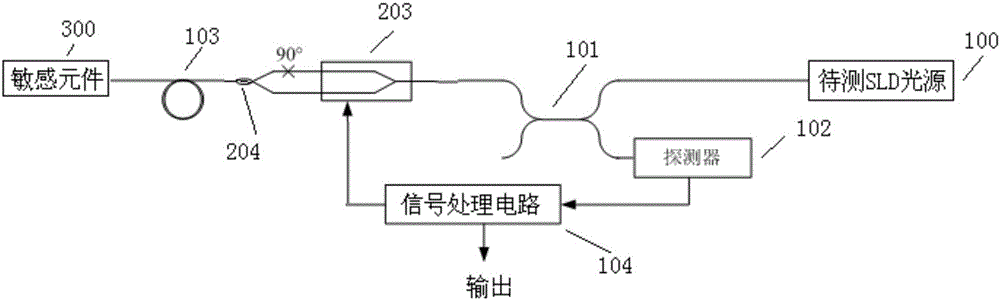

[0039] The present embodiment provides a kind of SLD light source testing system, such as figure 1 shown, including:

[0040] The first end of the coupler 101 receives the light emitted by the SLD light source 100 to be tested, and the second end is connected to the detector 102 .

[0041] The polarizer assembly 200 is connected to the third end of the coupler 101, and converts the light emitted by the SLD light source 100 to be tested into two beams of linearly polarized light, and the two beams of linearly polarized light are orthogonal.

[0042] Polarization maintaining fiber ring 103, its first end is connected with the output end of described polarizer assembly 200; Two beams of linearly polarized light enter described polarization maintaining fiber ring 103, along the fast axis and the fast axis of described polarization maintaining fiber ring res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com