A radiation-resistant optical fiber and its preparation process

A technology of anti-radiation and anti-radiation layer, which is applied in the direction of cladding optical fiber, multi-layer core/clad optical fiber, optics, etc., can solve the problems that have not been fundamentally solved, and achieve the goal of eliminating radiation interference and ensuring application safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

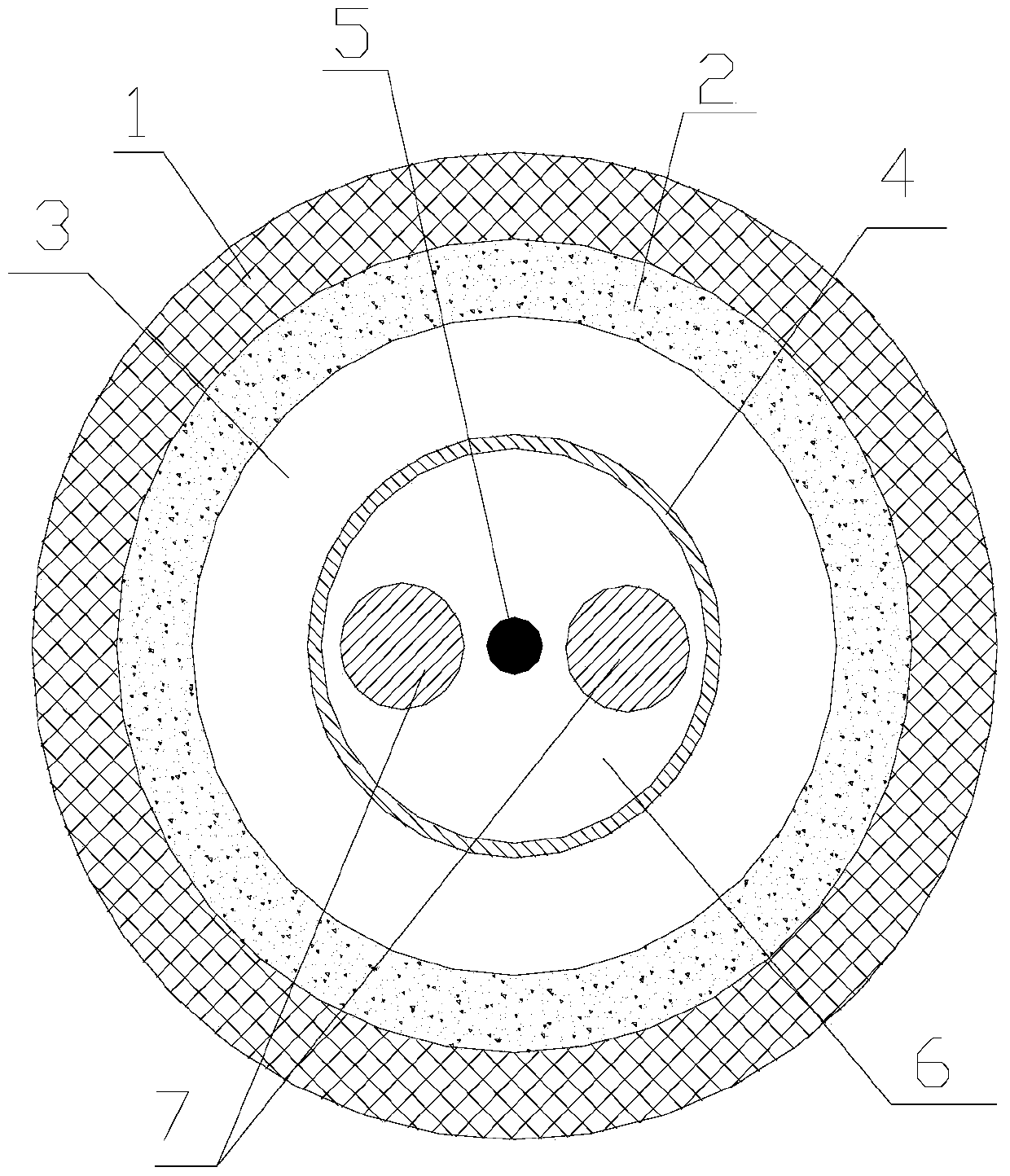

[0026] A radiation-resistant optical fiber, such as figure 1 As shown, it includes an optical fiber outer coating 1, an optical fiber inner coating 2, a quartz cladding 3, an anti-radiation layer 4, a stress region 7, an inner cladding 6 and a fiber core 5 arranged from outside to inside, wherein the quartz cladding 3 It is the outer cladding, wherein the outer coating is a polymeric organic compound doped with ions of variable valence metal elements, and the content is at the ppm level, wherein the optical fiber outer coating 1 contains 500ppm EuO, and the optical fiber inner coating 2 contains 400ppm EuO CeO 2 , containing 200ppm TiO in the anti-radiation layer 4 2 and used to compare the refractive index of the radiation resistant layer 4 with SiO 2 Flat fluorine, the core 5 contains Er with a mass ratio of 3:1 2 o 3 and CeO 2 and GeO to increase the refractive index of the core 2 , where CeO 2 The content is 600ppm, GeO 2 The content is 300ppm.

[0027] The concre...

Embodiment 2

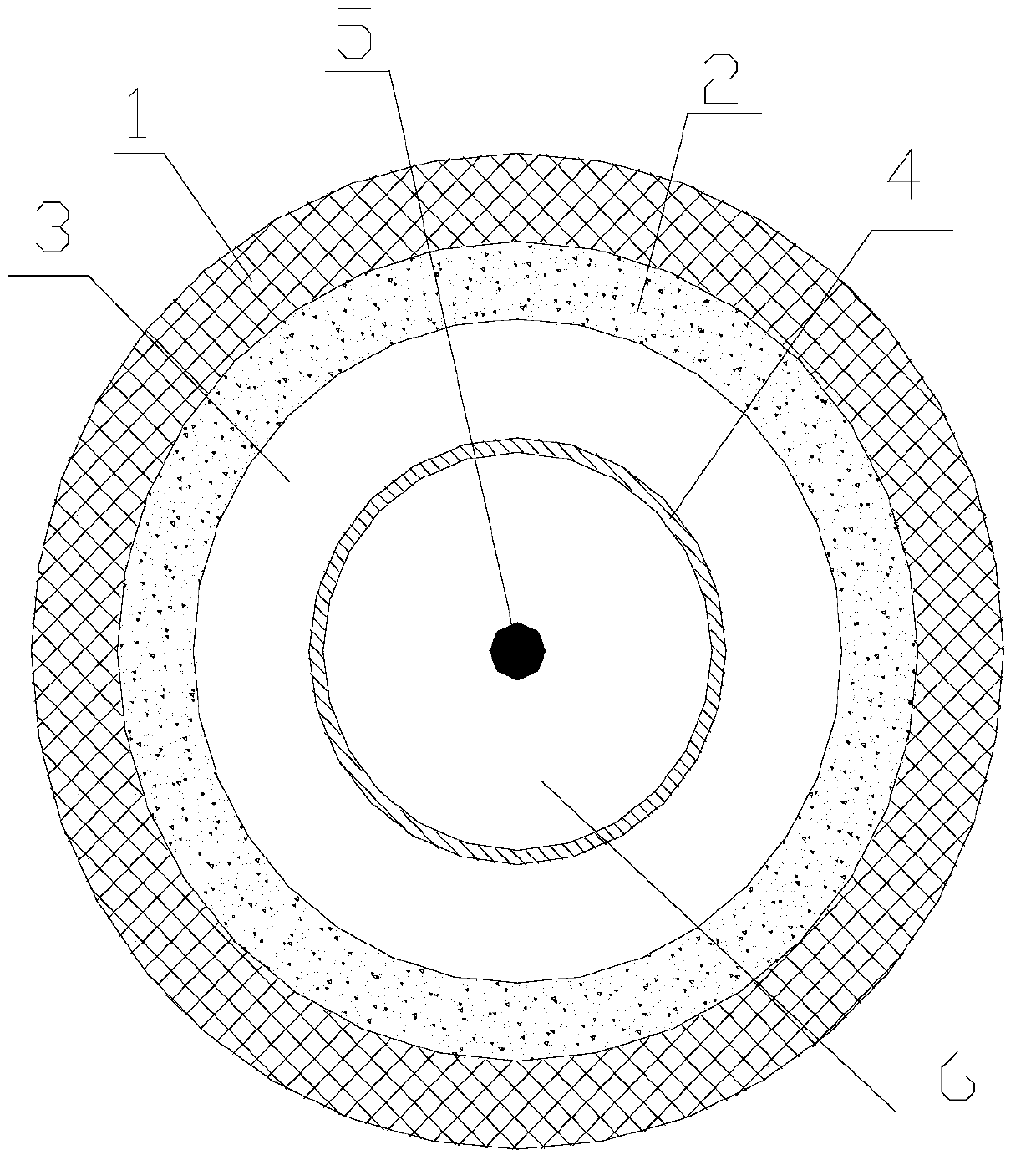

[0037] This embodiment is basically the same as Embodiment 1, except that the optical fiber structure of this embodiment does not include the stress zone 7 . The invention adds materials capable of anti-radiation effect to the outer layer coating, the outer cladding layer and the fiber core to form three anti-radiation defense lines, which can effectively resist the radiation.

Embodiment 3

[0039] This embodiment is similar to the steps of embodiment 1, by controlling the flow rate of the gaseous raw material that is introduced to generate deposits, the optical fiber outer coating 1 of the prepared optical fiber contains 200ppm Ce 2 o 3 , the fiber inner coating 2 contains 600ppm of PbO, and the anti-radiation layer 4 contains 300ppm of CeO 2 and used to compare the refractive index of the radiation resistant layer 4 with SiO 2 Flat fluorine, the core 5 contains Yb with a mass ratio of 3:1 2 o 3 and CeO 2 and GeO to increase the refractive index of the core 2 , where CeO 2 The content is 300ppm, GeO 2 The content is 400ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com