Machine-developing concentrated solution kit chemical for industrial X-ray films

A concentrated solution and X-ray technology, which is applied in the field of industrial X-ray film machine washing concentrated solution and medicine, can solve the problems of low photographic performance of film, damage to human health, defect detection rate, etc., to improve the maximum degree of blackening, prevent Irritant gas, contrast-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] specific implementation

[0038] In order to understand the present invention, the present invention will be further described below in conjunction with embodiment: following embodiment is illustrative, not limiting, can not limit protection scope of the present invention with following embodiment.

[0039] An industrial X-ray film machine flushing concentrate kit, which is composed of a developing concentrate and a fixing concentrate, wherein the developing concentrate is composed of a developing concentrate A, a developing concentrate B and a developing concentrate C, and the fixing concentrate is composed of a fixing concentrate Liquid A and Fixing Concentrate B, the specific composition and content of the above ingredients are as follows:

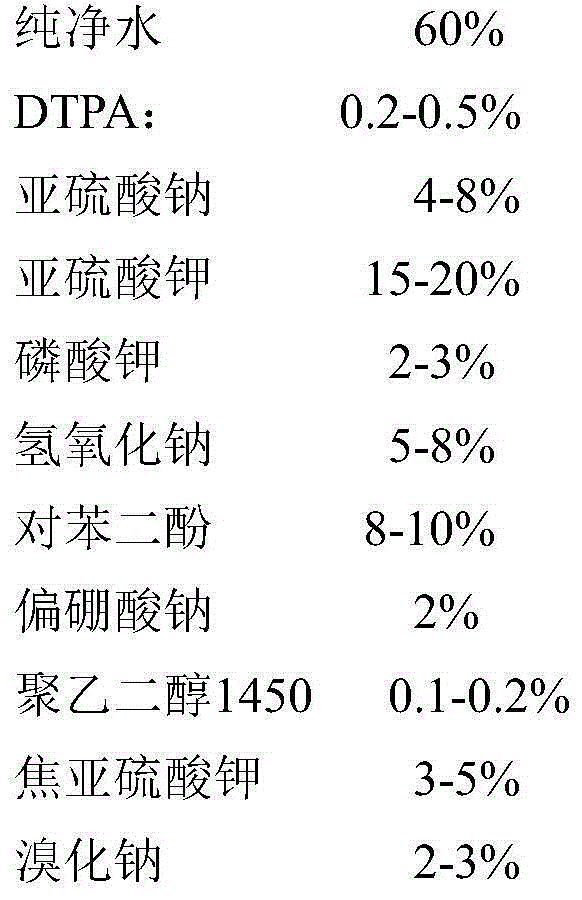

[0040] ⑴Development Concentrate A

[0041]

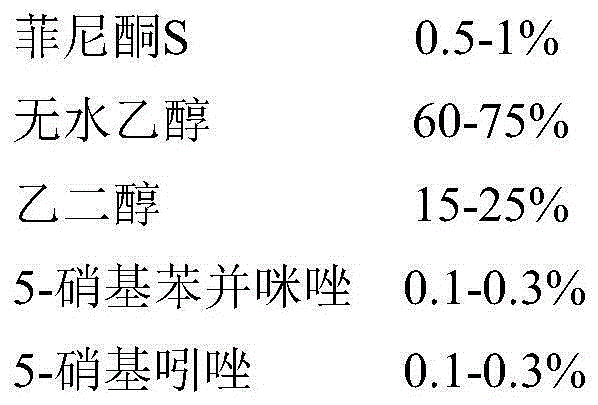

[0042] ⑵Development Concentrate B, the composition and content are as follows:

[0043]

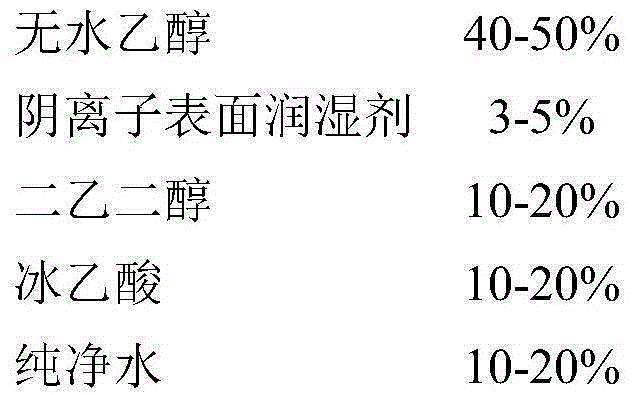

[0044] (3) Concentrated developing solution C, the composition and content are as foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| photosensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com