A kind of preparation method of civil ferrofluid

A ferrofluid and civil technology, applied in the field of ferrofluid, can solve problems such as product unevenness, toxic environment, pollution, etc., and achieve the effect of increasing life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

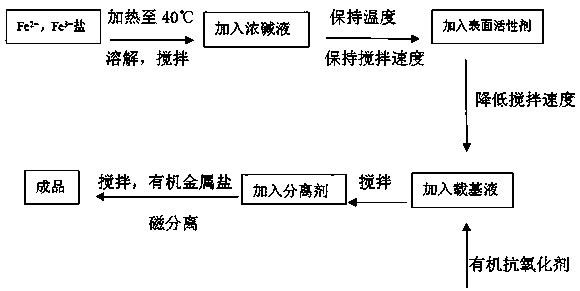

[0018] A preparation method of civil ferrofluid, the method comprises the following steps:

[0019] (1) Add Fe with a weight ratio of 1:1 to the three-necked flask 2+ , Fe 3+ salt, and dilute it to a total iron concentration of 0.5-2mol / L;

[0020] (2) Heating to 40°C under the condition that the mechanical stirring speed is 700-1500r / min;

[0021] (3) After stirring for 10-40min at 40°C, add 20-50ml of concentrated lye, and stir for 20-90min;

[0022] (4) Heat to 60-95°C and add 1-5ml of surfactant, reduce the stirring speed to 200-500r / min and keep stirring for 0.5-24h;

[0023] (5) After the stirring is completed, add the carrier liquid dissolved with organic antioxidant, continue to stir for 10-35mim, add 5-30ml of separating agent, stir for 10min, then add the organic metal salt solution accounting for 5-20% of the weight of the carrier liquid, Cool to room temperature and separate the two phases with a magnet.

Embodiment 1

[0032] A method for preparing civil magnetic fluid, the method is composed of the following steps:

[0033] (1) Add Fe with a weight ratio of 1:1 to the three-necked flask 2+ , Fe 3+ salt, and dilute it to a total iron concentration of 0.5mol / L;

[0034] (2) Heating to 40°C under the condition that the mechanical stirring speed is 700r / min;

[0035] (3) After stirring at 40°C for 10 minutes, add 20ml of concentrated lye, and stir for 20 minutes;

[0036] (4) Then heat to 60°C and add 1ml of surfactant, reduce the stirring speed to 200r / min and keep stirring for 0.5h;

[0037] (5) After the stirring is completed, add the carrier liquid dissolved with organic antioxidant, continue to stir for 10 minutes, add 5ml of separating agent, after stirring for 10 minutes, add an organic metal salt solution accounting for 5% of the weight of the carrier liquid, cool to room temperature and separate with a magnet Two phases are enough.

Embodiment 2

[0039] A method for preparing civil magnetic fluid, the method is composed of the following steps:

[0040] (1) Add weight ratio 1:1e to the three-necked flask 2+ , Fe 3+ salt, and dilute it so that the total iron concentration is 2mol / L;

[0041] (2) Heating to 40°C under the condition that the mechanical stirring speed is 1500r / min;

[0042] (3) After stirring at 40°C for 40 minutes, add 50ml of concentrated lye, and stir for 90 minutes;

[0043] (4) Then heat to 95°C and add 5ml of surfactant, reduce the stirring speed to 500r / min and keep stirring for 24h;

[0044] (5) After the stirring is completed, add the carrier liquid dissolved with organic antioxidants, continue to stir for 35 minutes, add 30ml of separating agent, and after stirring for 10 minutes, add an organic metal salt solution accounting for 20% of the weight of the carrier liquid, cool to room temperature and separate with a magnet Two phases are enough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com