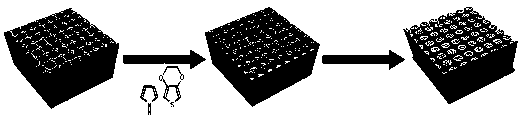

Pyrrole and 3,4-ethylenedioxythiophene copolymerized nanowire array and its preparation method

A dioxythiophene copolymerization nanometer and wire array technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor effect, limited effect of physical adsorption, and dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

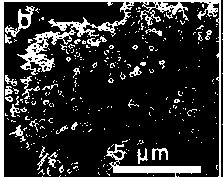

[0040]First, a layer of 1 μm thick Au was sputtered onto an alumina template with a pore diameter of 200 nm and a thickness of 60 mm as a conductive layer, and then using a three-electrode electrochemical deposition system, the alumina template was placed in an electrolytic cell as a conductive layer. Working electrode, silver / silver chloride electrode as reference electrode, platinum foil as counter electrode. Pyrrole and 3,4-ethylenedioxythiophene were reacted in chromatographically pure acetonitrile solution, the concentration of pyrrole was 10 mmol / L, the concentration of 3,4-ethylenedioxythiophene was 90 mmol / L, LiClO 4 The concentration is 0.1mol / L, using cyclic voltammetry, the scan rate is 0.05 V S -1 , the appropriate time to respond. After the reaction, the alumina template was selectively dissolved by 2mol / L NaOH solution, and then washed several times alternately with deionized water and ethanol. Finally, the obtained samples were rinsed several times with deioni...

Embodiment 2

[0042] First, a layer of 1 μm thick Au was sputtered onto an alumina template with a pore diameter of 200 nm and a thickness of 60 mm as a conductive layer, and then using a three-electrode electrochemical deposition system, the alumina template was placed in an electrolytic cell as a conductive layer. Working electrode, silver / silver chloride electrode as reference electrode, platinum foil as counter electrode. Pyrrole and 3,4-ethylenedioxythiophene were reacted in chromatographically pure acetonitrile solution, the concentration of pyrrole was 5 mmol / L, the concentration of 3,4-ethylenedioxythiophene was 70 mmol / L, LiClO 4 The concentration is 0.05mol / L, using cyclic voltammetry, the scan rate is 0.05 V S -1 , the appropriate time to respond. After the reaction, the alumina template was selectively dissolved by 2mol / L NaOH solution, and then washed several times alternately with deionized water and ethanol. Finally, the obtained samples were rinsed several times with deion...

Embodiment 3

[0044] First, a layer of 3 μm thick Au was sputtered onto an alumina template with a pore diameter of 200 nm and a thickness of 60 mm as a conductive layer, then using a three-electrode electrochemical deposition system, the alumina template was placed in an electrolytic cell as a conductive layer. Working electrode, silver / silver chloride electrode as reference electrode, platinum foil as counter electrode. Pyrrole and 3,4-ethylenedioxythiophene were reacted in chromatographically pure acetonitrile solution, the concentration of pyrrole was 20 mmol / L, the concentration of 3,4-ethylenedioxythiophene was 150 mmol / L, LiClO 4 The concentration is 0.5mol / L, using cyclic voltammetry, the scan rate is 0.05 V S -1 , the appropriate time to respond. After the reaction, the alumina template was selectively dissolved by 2mol / L NaOH solution, and then washed several times alternately with deionized water and ethanol. Finally, the obtained samples were rinsed several times with deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com